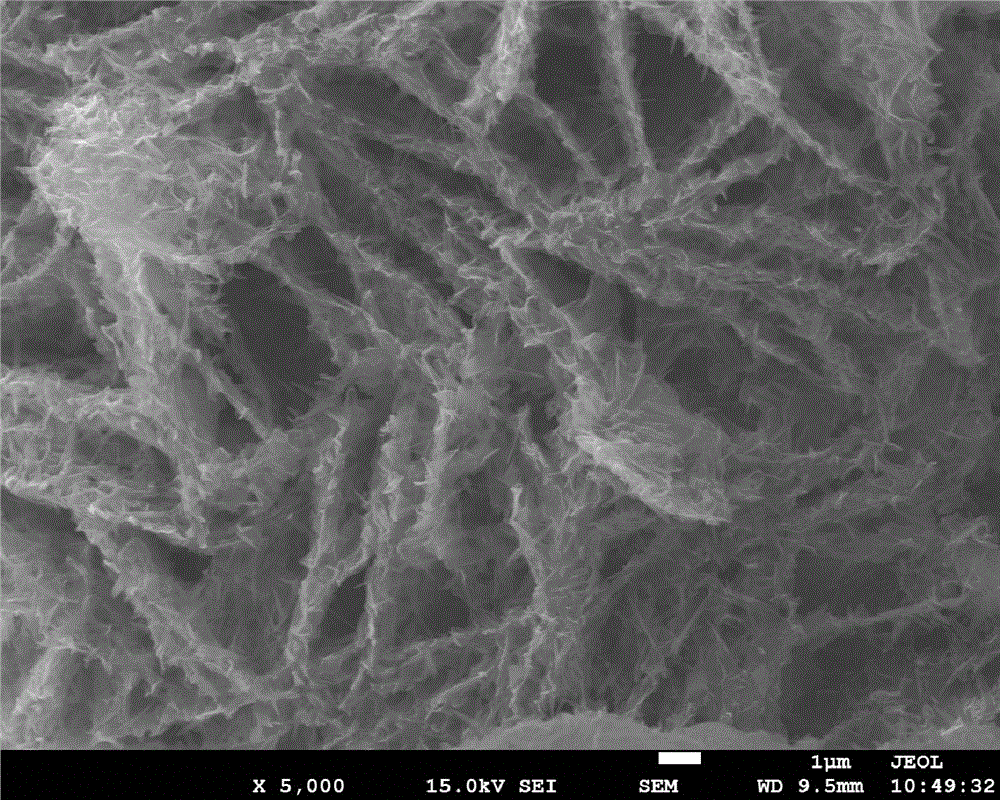

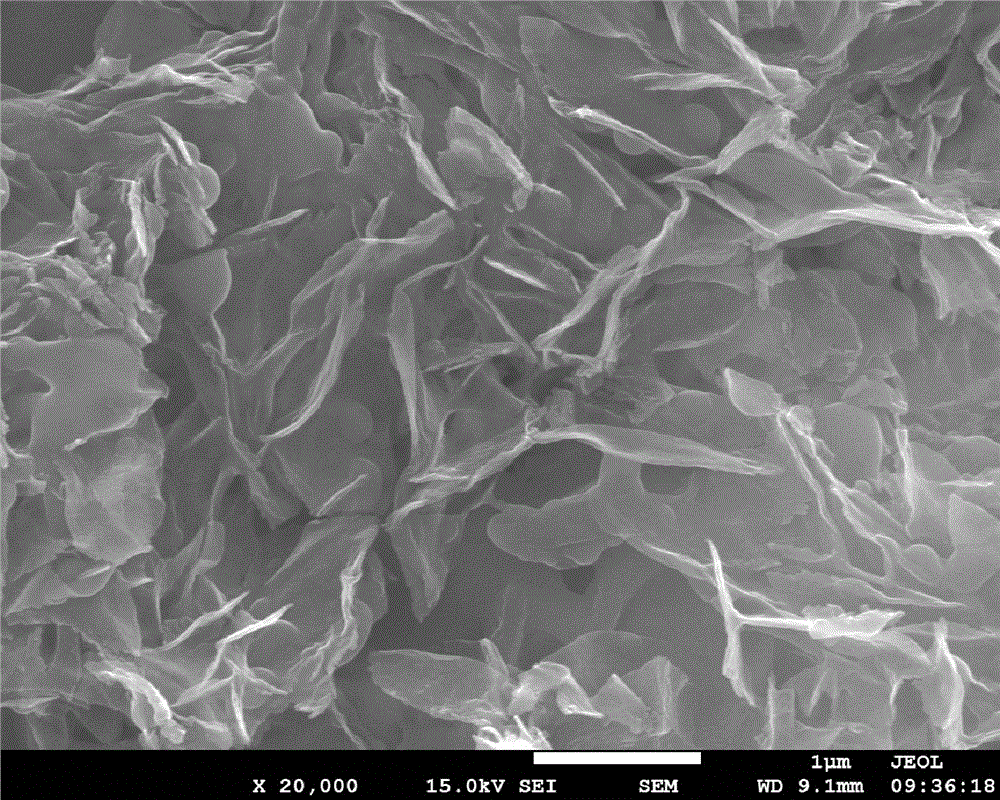

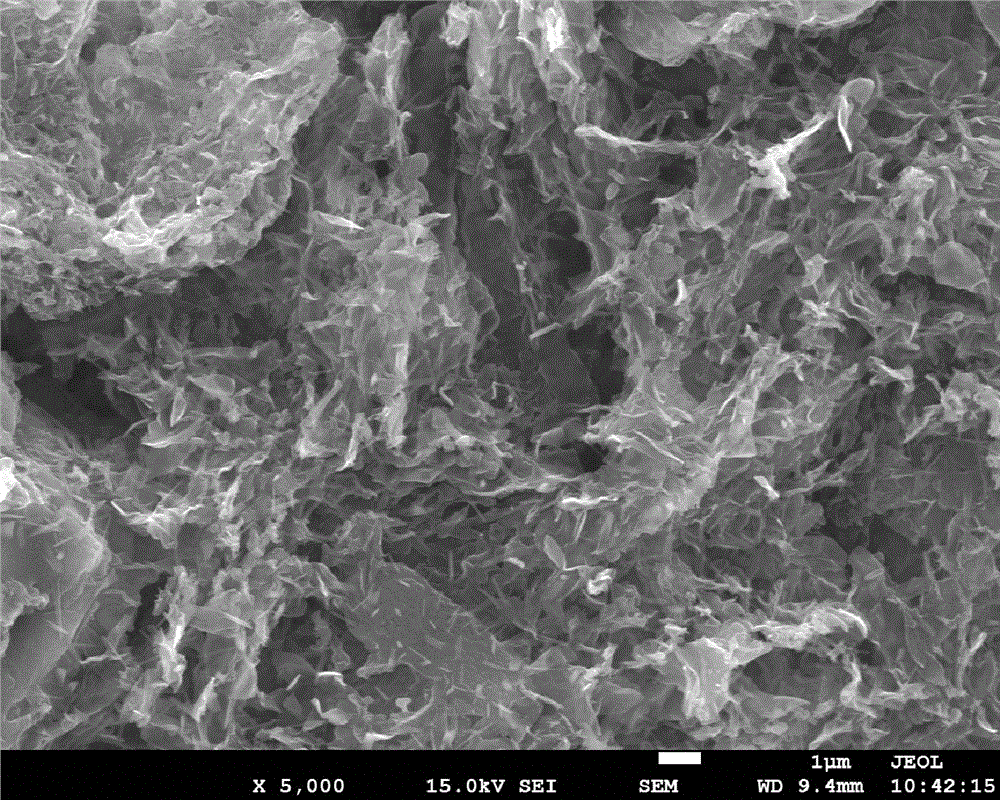

Method for preparing nano flaky nitrogen-containing porous carbon material

A technology of nano-flaky and porous carbon, which is applied in the preparation of sugar derivatives, chemical instruments and methods, and other chemical processes. It can solve the problems of porous carbon material pore structure changes, pore volume reduction, and high production costs. volume, promoting the formation of pores, and the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0023] Weigh the amount of potassium hydroxide and urea in Table 1 and dissolve them in 100ml of water, add the amount of cellulose in Table 1, disperse and mix evenly, after drying at 80°C, carbonize at 600°C, wash the carbonized product with water to obtain nano-sheet Nitrogen-containing porous carbon materials, test conditions and performance test results are shown in Table 1.

[0024]

Embodiment 7-12

[0026] Weigh the hydroxide or oxide in the amount in Table 2, dissolve it with urea in 100ml of water, add the cellulose in the amount in Table 2, disperse and mix evenly, dry at 80°C, carbonize at 700°C, and wash the carbonized product with water , to obtain nano-flaky nitrogen-containing porous carbon materials. The test conditions and performance test results are shown in Table 2.

[0027]

Embodiment 13-18

[0029] Weigh the amount of potassium hydroxide in Table 3 and the water-soluble amine-containing compound and dissolve them in 100ml of water, add the amount of cellulose in Table 3, disperse and mix evenly, dry at 80°C, carbonize at 800°C, wash the carbonized The product was obtained as a nano-flaky nitrogen-containing porous carbon material. The test conditions and performance test results are shown in Table 3.

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com