Lightweight concrete material and preparation method thereof

A lightweight concrete and lightweight aggregate technology, applied in the field of building materials, can solve the problems that the durability of materials cannot be completely and effectively improved, affect the normal use of engineering structures, and poor bonding and compactness, so as to improve mechanical strength, bonding The effect of performance improvement and mechanical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

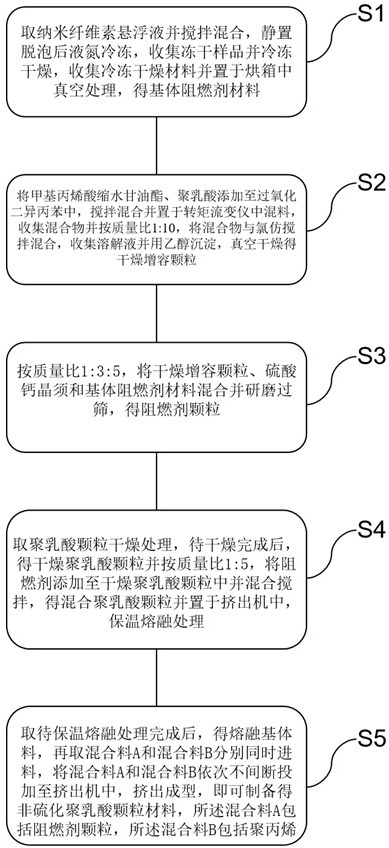

Method used

Image

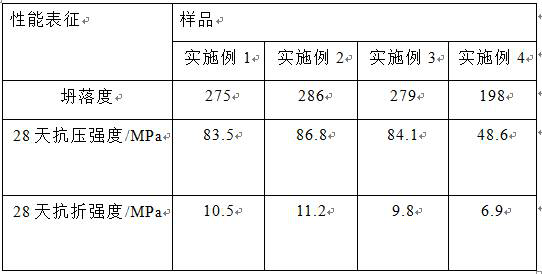

Examples

Embodiment 1

[0034] In terms of parts by weight, weigh 45 parts of POE resin, 35 parts of PX105 wax and 35 parts of EVA resin, mix them in a drying oven, and then dry them at 25°C for 1 hour, mix them and place them in an internal mixer, and control the density. The temperature zone of the mixing machine is 135°C and the speed is 45r / min. After banburying and blending for 15 minutes, the mixed elastomer is collected; in parts by weight, 45 parts of deionized water, 10 parts of peach gum and 3 parts of carbonic acid Sodium hydrogen was stirred and mixed at room temperature and swelled for 6 hours. The mixed solution was collected and homogenized to obtain a homogeneous solution; in parts by weight, 45 parts of homogeneous solution, 15 parts of kaolin, and 45 parts of diatomaceous earth were weighed. Mix with 6 parts of tungsten slag in a mixer and grind through a 200-mesh sieve, collect the sieved slurry and granulate it, control the granulation particle size to 3mm, collect the mixed partic...

Embodiment 2

[0036]In parts by weight, 47 parts of POE resin, 37 parts of PX105 wax and 37 parts of EVA resin were weighed and mixed in a drying oven, and then dried at 27°C for 1 hour, mixed and placed in an internal mixer, and the density was controlled. The temperature zone of the mixing machine is 135°C, the speed is 47r / min, and after banburying and blending for 17 minutes, the mixed elastomer is collected; in parts by weight, 47 parts of deionized water, 12 parts of peach gum and 4 parts of carbonic acid Sodium hydrogen was stirred and mixed at room temperature and swelled for 7 hours. The mixed solution was collected and homogenized to obtain a homogeneous solution; in parts by weight, 47 parts of homogeneous solution, 17 parts of kaolin, and 47 parts of diatomaceous earth were weighed. Mix with 7 parts of tungsten slag in a mixer and grind them through a 200-mesh sieve, collect the sieved slurry and granulate, control the granulation particle size to 4mm, collect the mixed particles...

Embodiment 3

[0038] In parts by weight, 50 parts of POE resin, 40 parts of PX105 wax and 40 parts of EVA resin were weighed and mixed in a drying oven, and then dried at 30°C for 2 hours, mixed and placed in an internal mixer, and the density was controlled. The temperature zone of the mixing machine is 135°C, the speed is 50r / min, after banburying and blending for 20min, the mixed elastomer is collected; in parts by weight, 50 parts of deionized water, 15 parts of peach gum and 5 parts of carbonic acid Sodium hydrogen was stirred and mixed at room temperature and swelled for 8 hours. The mixed solution was collected and homogenized to obtain a homogeneous solution; in parts by weight, 50 parts of homogeneous solution, 20 parts of kaolin, and 50 parts of diatomaceous earth were weighed. Mix with 8 parts of tungsten slag in a mixer and grind them through a 200-mesh sieve, collect the sieved slurry and granulate, control the granulation particle size to 5mm, collect the mixed particles and pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com