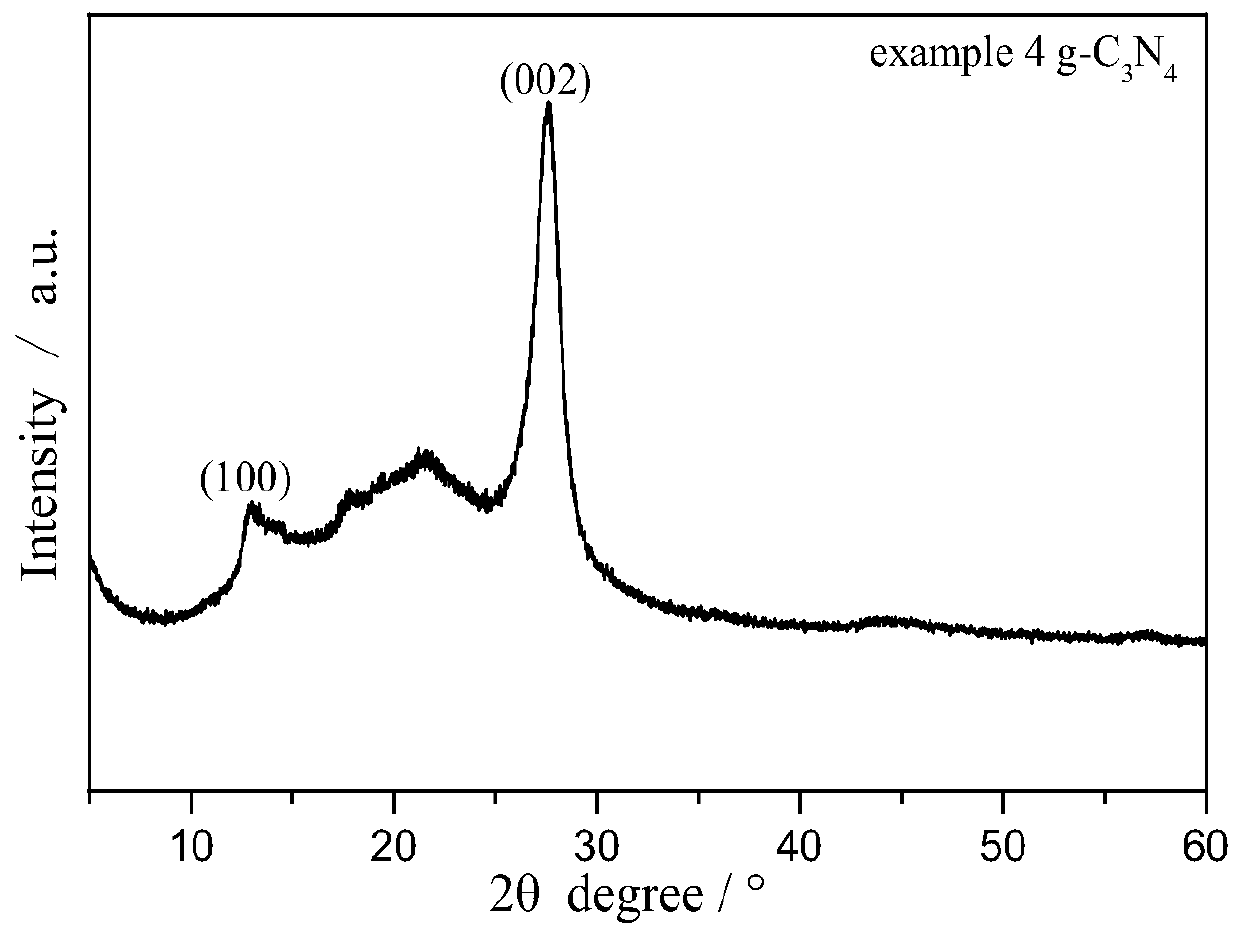

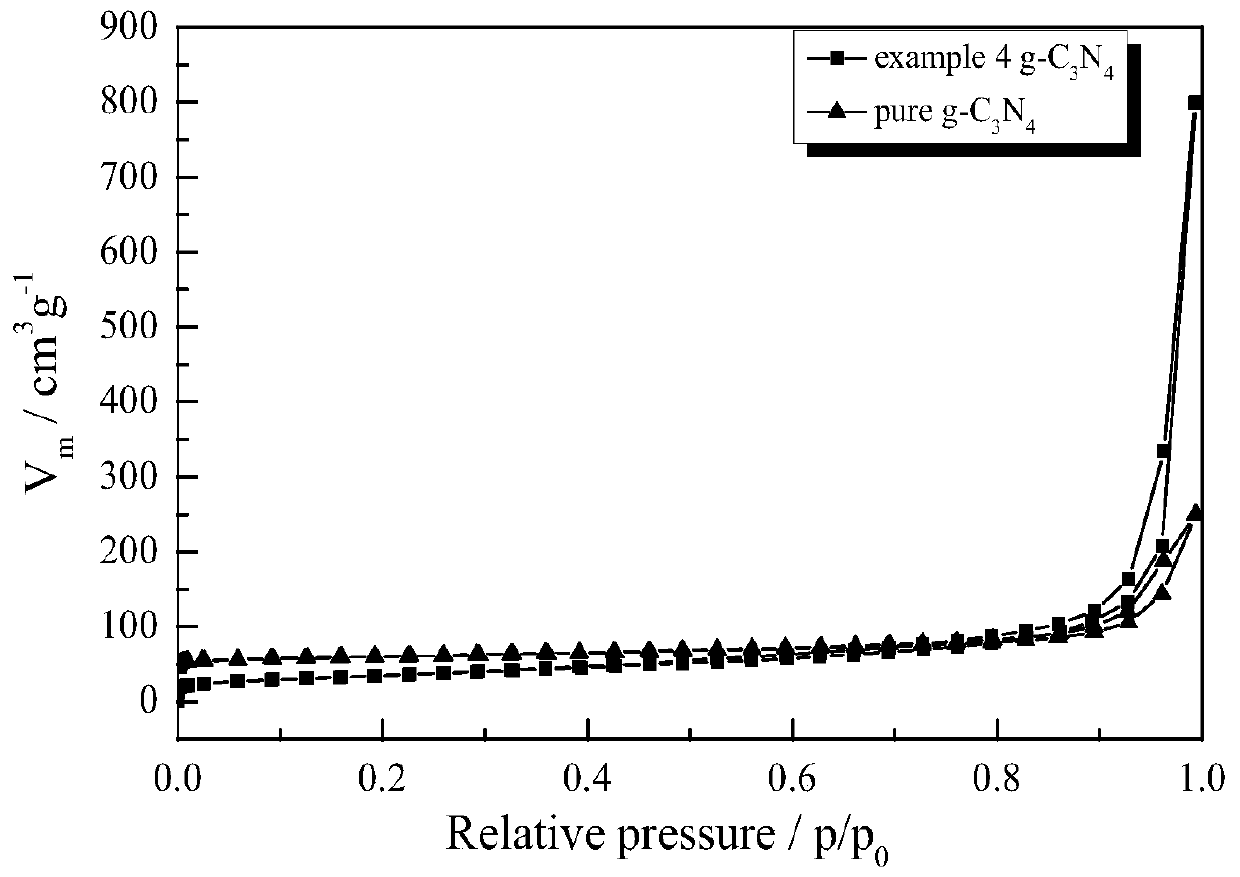

Preparation method of graphite-phase carbon nitride with large specific surface area

A technology of graphite phase carbon nitride and large specific surface area, which is applied in the fields of chemical instruments and methods, inorganic chemistry, hydrogen production, etc. It can solve the problems that the template agent does not conform to green chemistry, is volatile and corrosive, and improves the specific surface area. , to avoid structural defects and environmental pollution, fast transfer speed, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of graphite phase carbon nitride with large specific surface area is implemented as follows:

[0029] (1) Take a certain amount of nitrogen-containing precursor into a three-necked flask;

[0030] (2) Put the three-necked flask containing the nitrogen-containing precursor into the oil bath, and heat and stir for 0.5-2h under the heating condition of 135~180℃;

[0031] (3) After the heating and stirring are completed, take the three-necked flask out of the oil bath, wait for the molten urea to cool and crystallize at room temperature, grind the obtained solid crystals into powder, and then roast it in an air atmosphere;

[0032] The specific steps are as follows: in the muffle furnace, the temperature is raised to 200°C at a temperature rise rate of 5-20°C / min and kept for 0.5-2h. After keeping it for a certain period of time, the temperature is increased to 400-650°C at a heating rate of 5-20°C / min, and it is calcined for 1 to 4 hours.

[0033] In the abov...

Embodiment 1

[0044] (1) Put the three-necked flask containing 25g of urea into the oil bath, the temperature of the oil bath is 135 o C, heating and stirring for 2h. The molten urea is cooled and crystallized at room temperature.

[0045] (2) Grind the obtained solid crystals into powder, put them in a crucible and cover them, and put the covered crucible into the muffle furnace. o C / min heating rate, first heating up to 200 o Keep C for 1h, then heat up to 400 o C, roasting for 4h. It is naturally cooled to room temperature, and the solid product is ground to obtain graphite phase carbon nitride with a large specific surface area.

Embodiment 2

[0047] (1) Put the three-necked flask with 25g of urea into the oil bath, the temperature of the oil bath is 140 o C, heating and stirring for 1.5h. The molten urea is cooled and crystallized at room temperature.

[0048] (2) Grind the obtained solid crystal into powder, put it in a crucible, cover it, put the covered crucible into the muffle furnace, and reduce it to 10 o C / min heating rate, first heating up to 200 o Keep C for 1h, then heat up to 450 o C, roasting for 3h. It is naturally cooled to room temperature, and the solid product is ground to obtain graphite phase carbon nitride with a large specific surface area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com