High-activity graphite-phase carbon nitride material and preparation method thereof

A graphite-phase carbon nitride and high-activity technology, applied in chemical instruments and methods, chemical/physical processes, special compound water treatment, etc., can solve the problem of low efficiency of photocatalytic degradation of pollutants, difficulty in effectively regulating the preparation process, Thermal polymerization duration and other issues, to achieve excellent photocatalytic activity, excellent adsorption performance, and reduce the effect of carrier recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

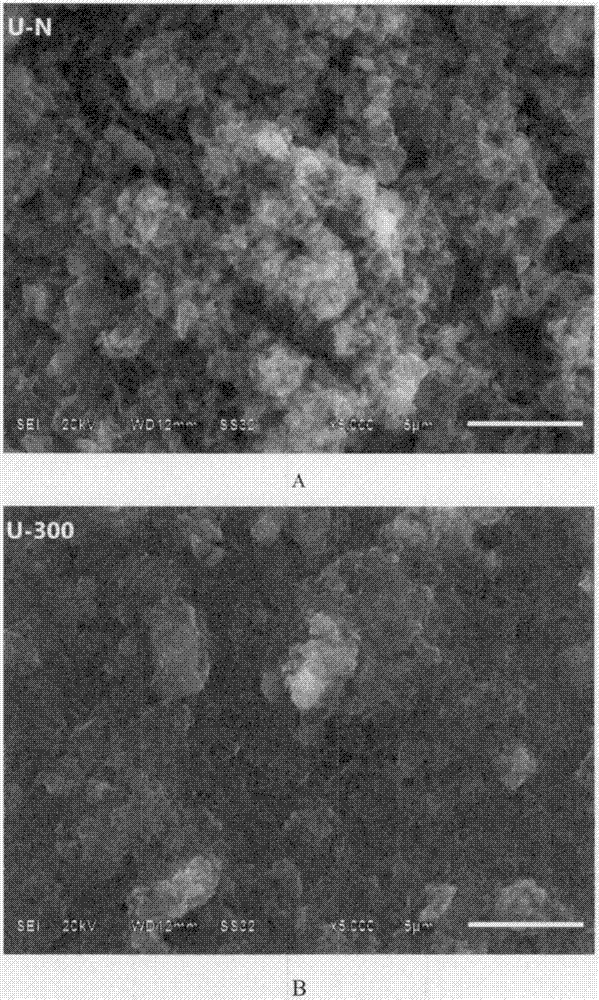

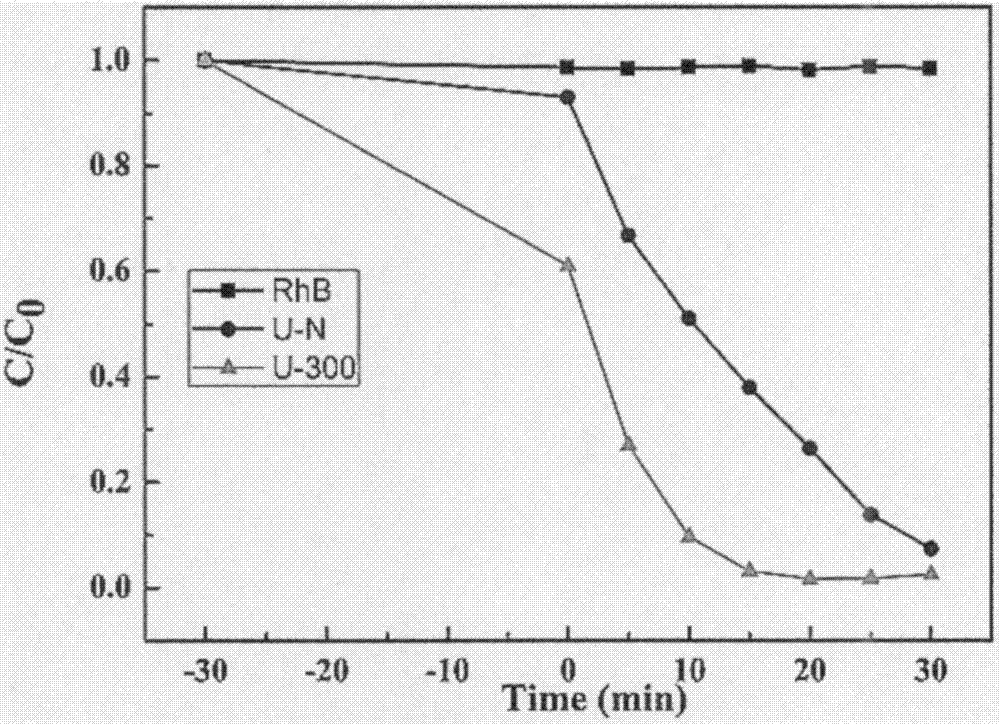

[0060] A method for preparing a highly active graphite phase carbon nitride material provided in an embodiment of the present invention comprises the following steps:

[0061] (1) Take 5 grams of urea and put it in a capped quartz porcelain boat, and place it in a tubular graphite furnace;

[0062] (2) Under the protection of nitrogen flow, the temperature was programmed to rise to 300°C at a heating rate of 5°C / min, and the feeding of nitrogen gas was immediately stopped to keep the heating rate constant;

[0063] (3) Continue to heat up to 550°C and keep for 4h;

[0064] (4) After cooling, grind to obtain a light yellow powder, which is the porous graphite phase carbon nitride material (U-300).

Embodiment 2

[0068] A method for preparing a highly active graphite phase carbon nitride material provided in an embodiment of the present invention comprises the following steps:

[0069] (1) Take 5 grams of urea and put it in a capped quartz porcelain boat, then place it in a tubular graphite furnace;

[0070] (2) Under the protection of nitrogen flow, the temperature was programmed to rise to 400°C at a heating rate of 5°C / min, and the feeding of nitrogen gas was immediately stopped to keep the heating rate constant;

[0071] (3) Continue to heat up to 550°C and keep for 4h;

[0072] (4) After cooling, grind to obtain a light yellow powder, which is the porous graphite phase carbon nitride material (U-400).

Embodiment 3

[0076] A method for preparing a highly active graphite phase carbon nitride material provided in an embodiment of the present invention comprises the following steps:

[0077] (1) Take 5 grams of urea and put it in a capped quartz porcelain boat, then place it in a tubular graphite furnace;

[0078] (2) Under the protection of nitrogen flow, the temperature was programmed to rise to 500°C at a heating rate of 5°C / min, and the feeding of nitrogen gas was immediately stopped to keep the heating rate constant;

[0079] (3) Continue to heat up to 550°C and keep for 4h;

[0080] (4) After cooling, grind to obtain light yellow powder, which is the porous graphite phase carbon nitride material (U-500).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com