Birotor permanent magnet motor and washing machine

A technology of permanent magnet motor and double rotor, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of inability to realize washing machines at the same time, limited rotor speed, etc., and achieve the effect of overcoming loud noise and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

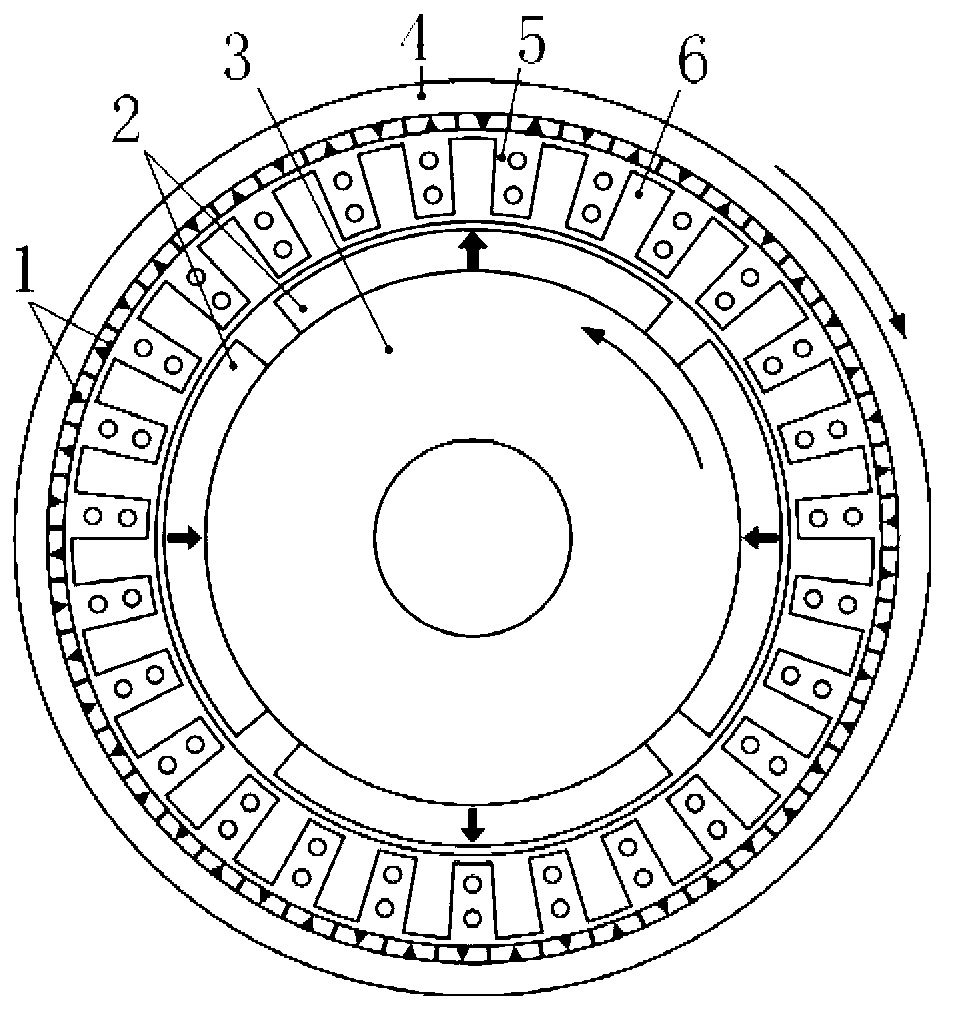

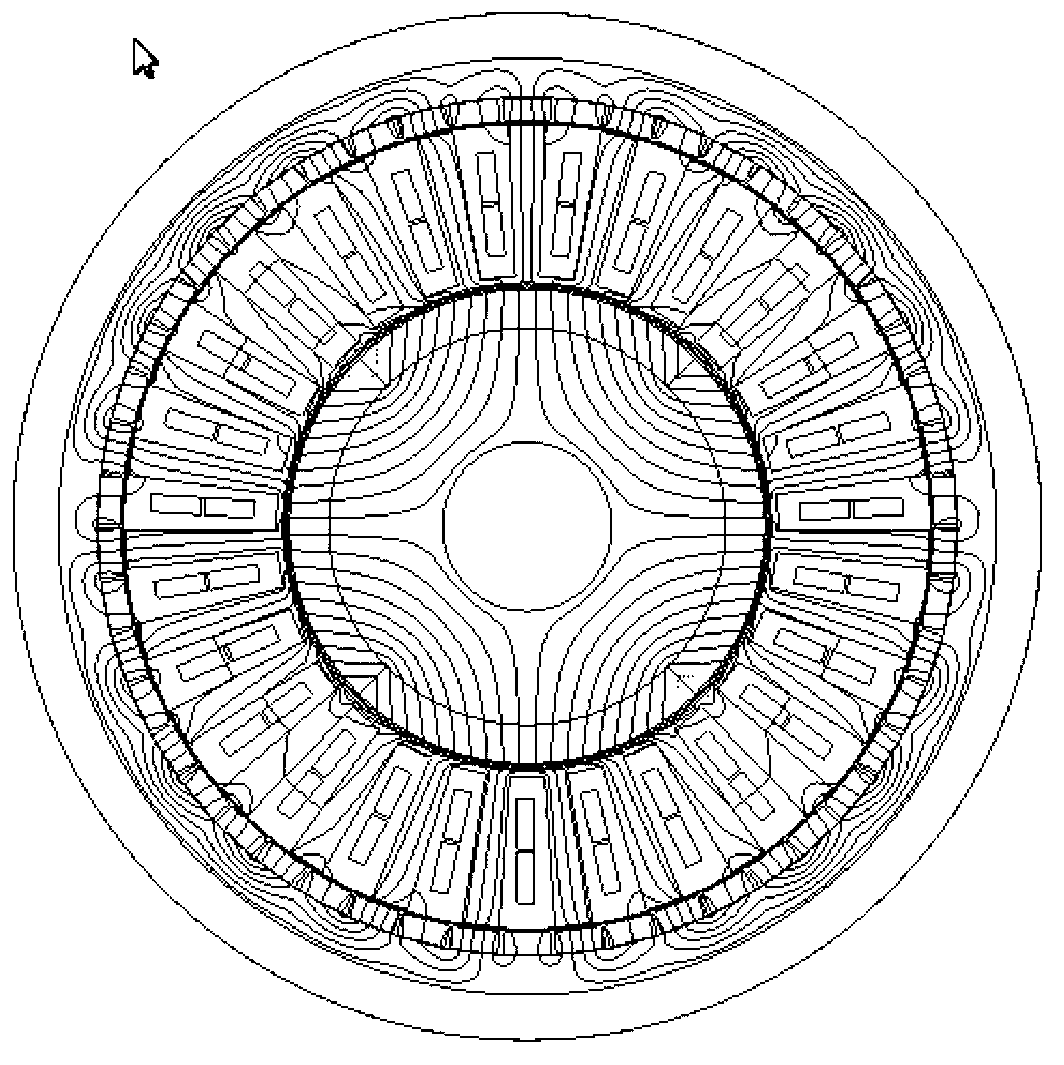

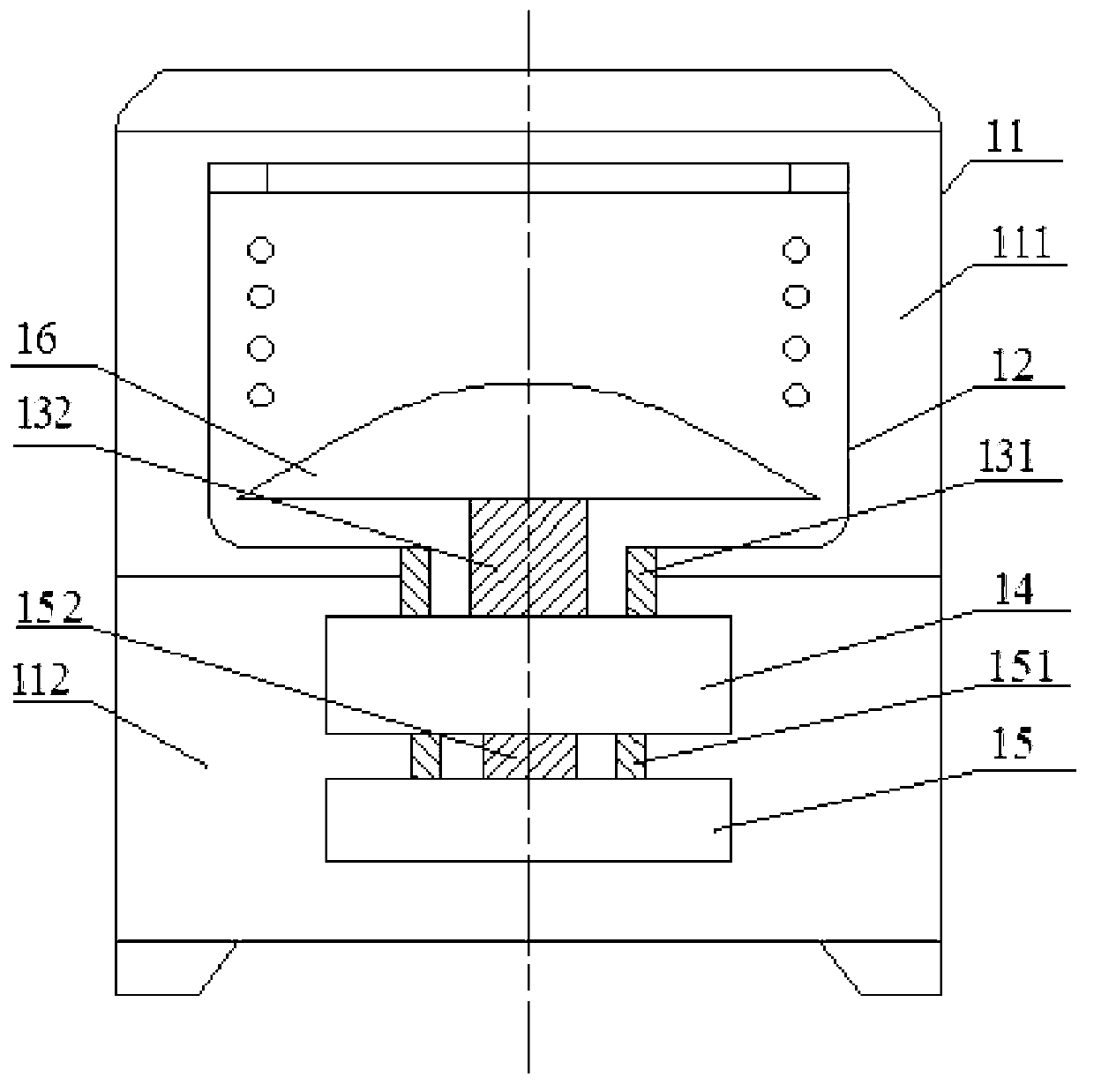

[0029] Such as figure 1 As shown, a double-rotor permanent magnet motor according to an embodiment of the present invention includes an inner rotor, a stator, and an outer rotor arranged sequentially from the inside to the outside, that is, the stator is located in the air gap between the inner rotor and the outer rotor, and the inner and outer rotors are connected to the stator. There are also air gaps between them.

[0030] The outer rotor punching plate 4 and the outer rotor permanent magnet 1 form the outer rotor; the inner rotor iron yoke 3 and the inner rotor permanent magnet 2 form the inner rotor; the magnetic modulation ring and the stator winding 5 form the stator, and the magnetic modulation ring belts are evenly distributed along the circumferential direction. There are a plurality of magnetization adjusting teeth 6, and there are tooth slots between adjacent magnetic tuning teeth, and each effective side of the stator winding is arranged in the corresponding tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com