Rotary milling vibration measuring instrument

A technology of vibration measurement and milling, which is applied in the field of metal cutting and can solve problems such as long distances and different vibration signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

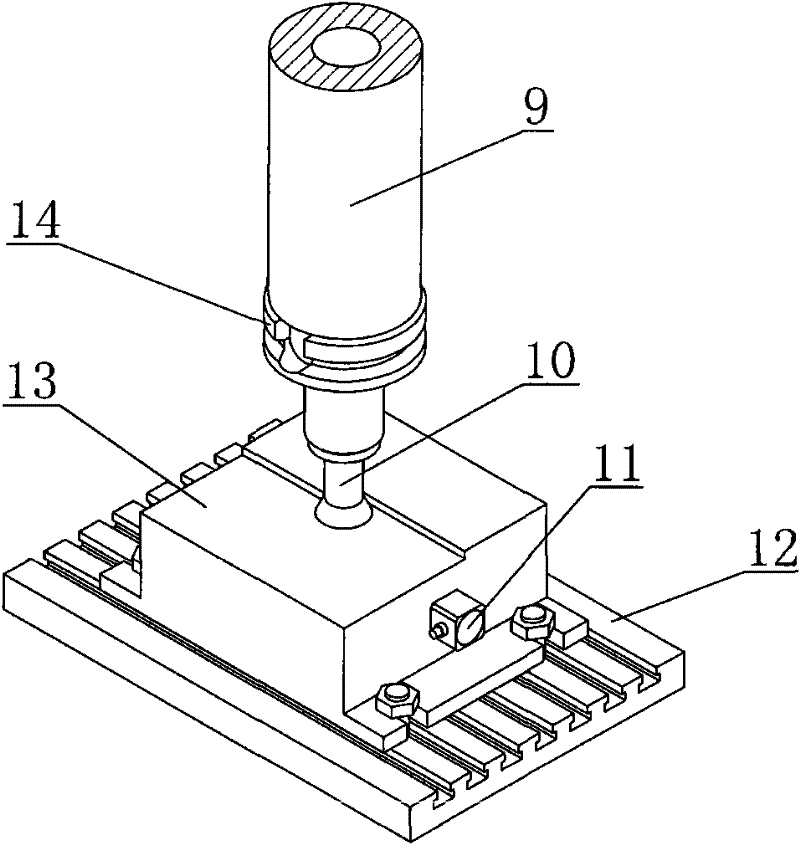

[0037] The present invention will be further described below in conjunction with the examples shown in the accompanying drawings. The rotary milling vibration measuring instrument of the present invention comprises:

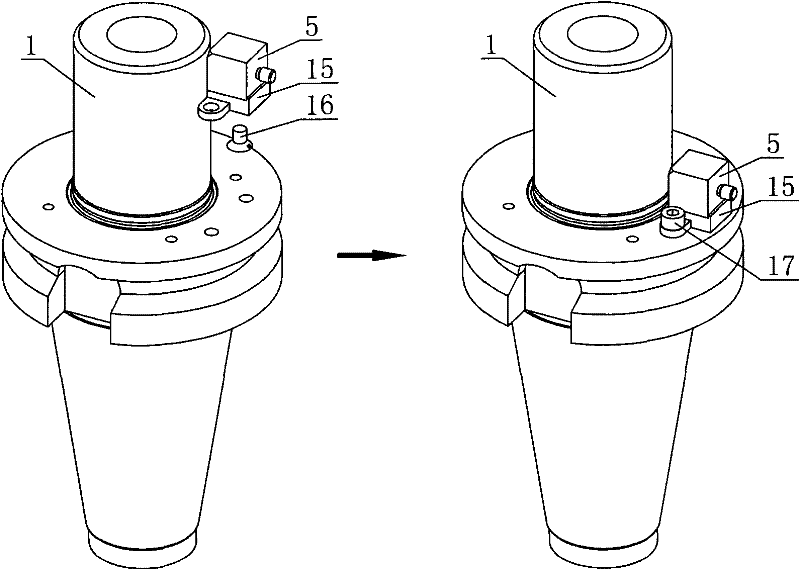

[0038] 1. Install the vibration sensor on the milling cutter holder

[0039] Install the vibration sensor Milling tool holder 1 is the main body of the rotary vibration measuring instrument, which is used to connect the rotary vibration measuring instrument to the spindle of the machine tool (through the taper surface) and install the tool, see figure 2 , The conical shank of the milling cutter holder 1 with the vibration sensor installed complies with the BT50 national standard (GB / T 10944.1-2006). First, the built-in IC piezoelectric crystal acceleration sensor 5 and the sensor mounting base 15 are fixed together by screws 16, and then the combination of the built-in IC piezoelectric crystal acceleration sensor 5 and the sensor mounting base 15 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com