Sixteen-color weft selecting device

A sixteen-color, weft-selecting technology, which is applied in textiles, textiles, papermaking, looms, etc., can solve problems such as the electromagnetic coil is easily damaged, the action and inertia of the color selection mechanism are large, and it can reduce broken ends, increase the number, and enrich The effect of fabric patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

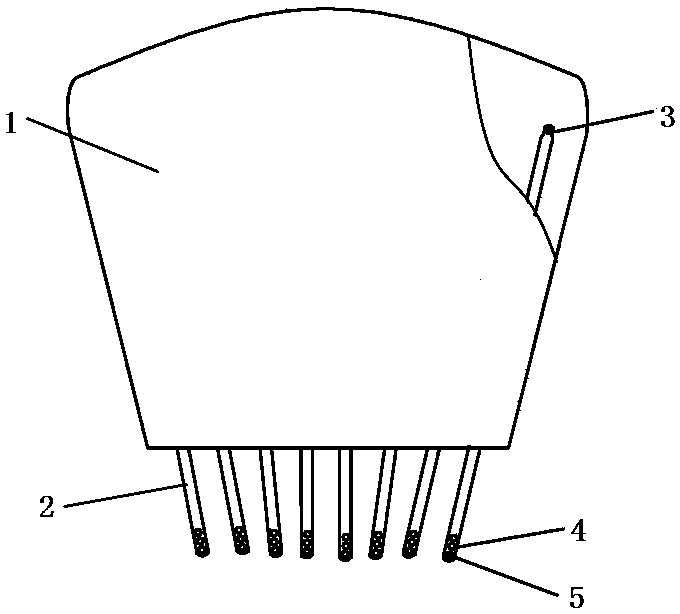

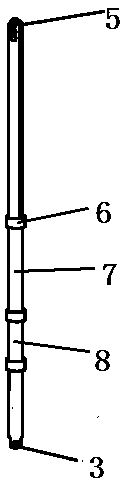

[0020] see Figure 1-2 , a sixteen-color weft selection device, comprising two rows of weft selection needles 2 arranged in parallel, the weft selection needles 2 are installed in a fan-shaped housing 1, and the number of weft selection needles 2 in each row is 8, characterized in that: Described weft selection needle 2 comprises needle head 4, guide rod 7, inertia impact rod 8 and needle tail 3, and described needle head 4, guide rod 7, inertia impact rod 8 and needle tail 3 are connected by boss 6, and described guide rod 7 is a hollow structure, which has a compression spring inside, and exerts force on the contact surface of the inertial impact rod 8, so that the compression spring abuts and engages with one end of the inertial impact rod 8, and the inner diameter of the guide rod 7 is larger than that of the inertial impact rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com