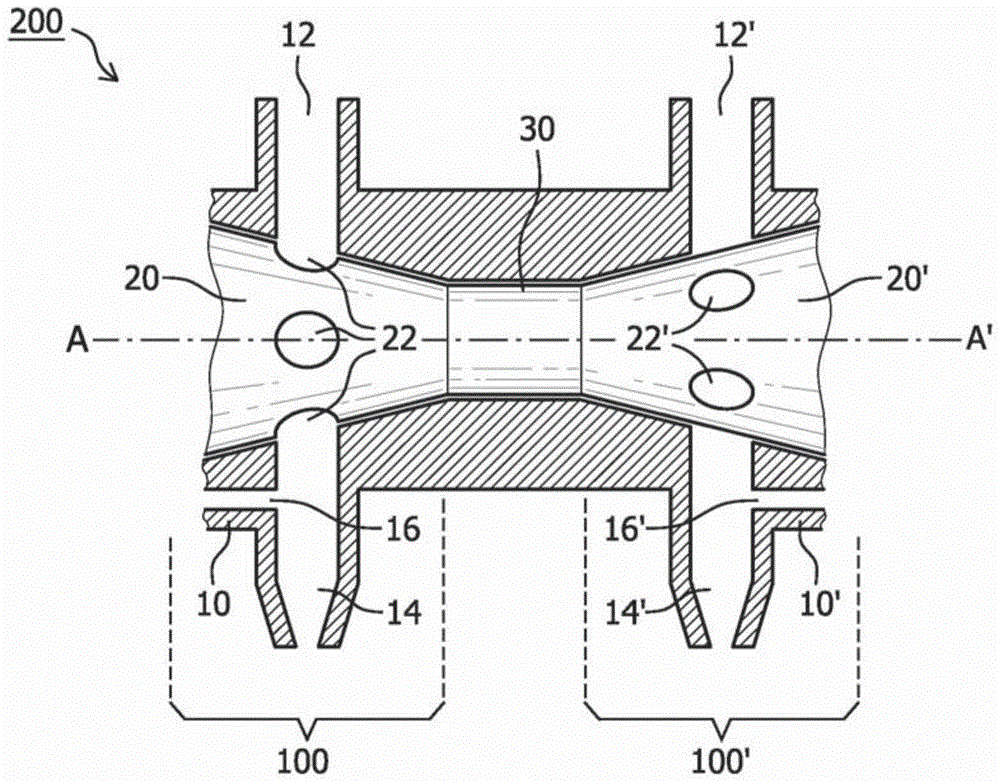

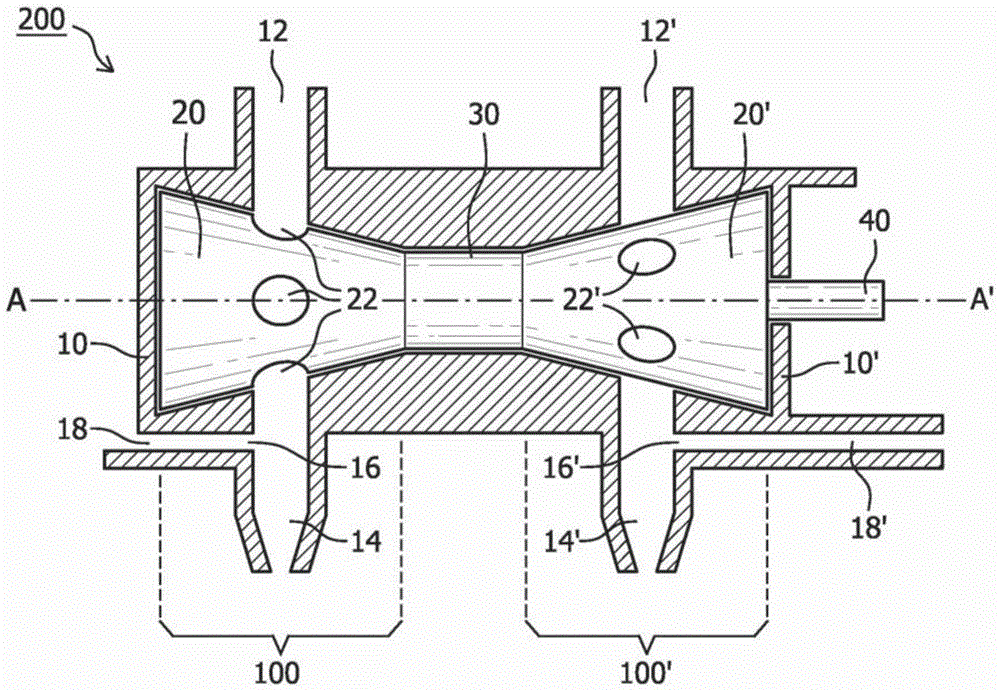

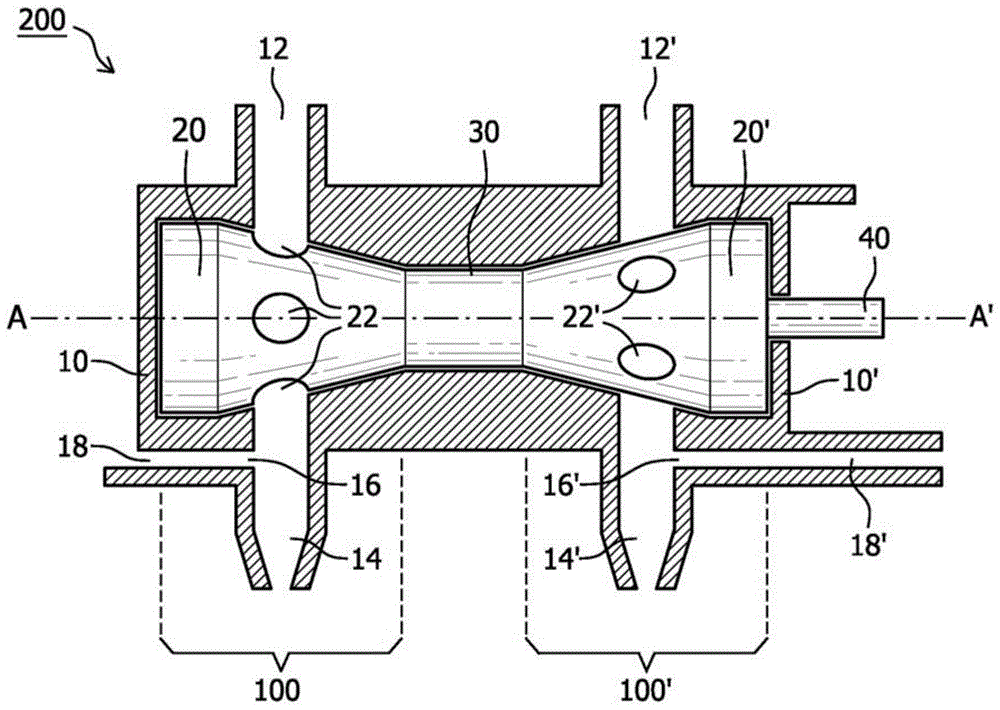

Continuous feed metering device

A technology of granular materials and rotors, applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of downstream applications, unstable reactor operation, unstable catalyst feeding, etc., to reduce wear, reduce The effect of rotation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0103] Calculation of cavity volume.

[0104] The cavity of the rotor can have a volume that depends on several factors including desired dispense rate, rotor speed, size and application. As a general guide, when the application is distributing catalyst for a polymerization reactor, the cavity of the rotor may have a diameter of about 1 to about 100 cm 3 , preferably about 20 to about 70 cm 3 , more preferably from about 20 to about 100 cm 3 volume.

[0105] The cavity of the rotor may have a volume calculated according to equation [1]. For a reactor with a production capacity Q (ton / h), a catalyst with a productivity P (gPE / g catalyst), and a catalyst bulk density MVA (g / cm 3 ), the rotational speed RPM of rotor, calculate volume V, it is the required volume in one rotation of the device of the present invention that comprises two rotors:

[0106] V = Q . 10 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com