Golf ball

a golf ball and ball technology, applied in the field of golf balls, can solve the problems of increasing spin rate, poor controllability and diminished feel, difficult to achieve an increased distance, etc., and achieve the effect of reducing the spin rate on shots, good distance, and suitable spin rate on shots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

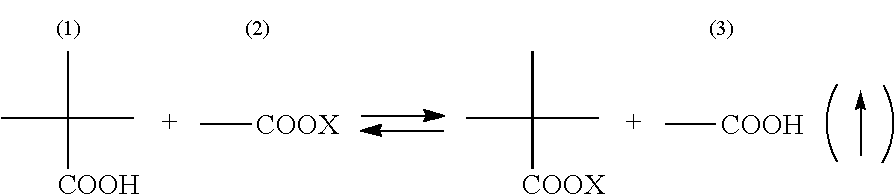

Method used

Image

Examples

examples

[0110]The following Examples and Comparative Examples are provided by way of illustration and not by way of limitation.

examples 1 to 3

, Comparative Examples 1 to 4

Formation of Core

[0111]Solid cores were fabricated by preparing the rubber compositions shown in Table 1 below, then molding and vulcanizing at 155° C. for 15 minutes.

TABLE 1FormulationNo. 1No. 2FormulationPolybutadiene100100(pbw)Dicumyl peroxide1.21.2Zinc oxide18.0219.142,2′-Methylenebis(4-methyl-6-t-0.10.1butylphenol)Zinc diacrylate32.7129.99Zinc salt of pentachlorothiophenol0.100.10

[0112]Details on the materials in Table 1 are given below.[0113]Polybutadiene: Available under the trade name “BR 730” from JSR Corporation.[0114]Dicumyl peroxide: Available under the trade name “Percumyl D” from NOF Corporation.[0115]Zinc oxide: Available from Sakai Chemical Industry Co., Ltd.[0116]2,2′-Methylenebis(4-methyl-6-t-butylphenol): Available under the trade name “Nocrac NS-6” from Ouchi Shinko Chemical Industry Co., Ltd.[0117]Zinc diacrylate: Available from Nihon Jyoryu Kogyo Co., Ltd.[0118]Zinc salt of pentachlorothiophenol:[0119]Available from Tokyo Kasei Kogy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com