Novel humidity adjusting anti-bacterial environment-friendly diatom ooze wall material and preparing method thereof

A technology for diatom mud and wall materials, which is applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problems of limited air purification ability, insignificant humidity control effect, and insignificant antibacterial effect. , to achieve the effect of simple preparation method, excellent humidity control performance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

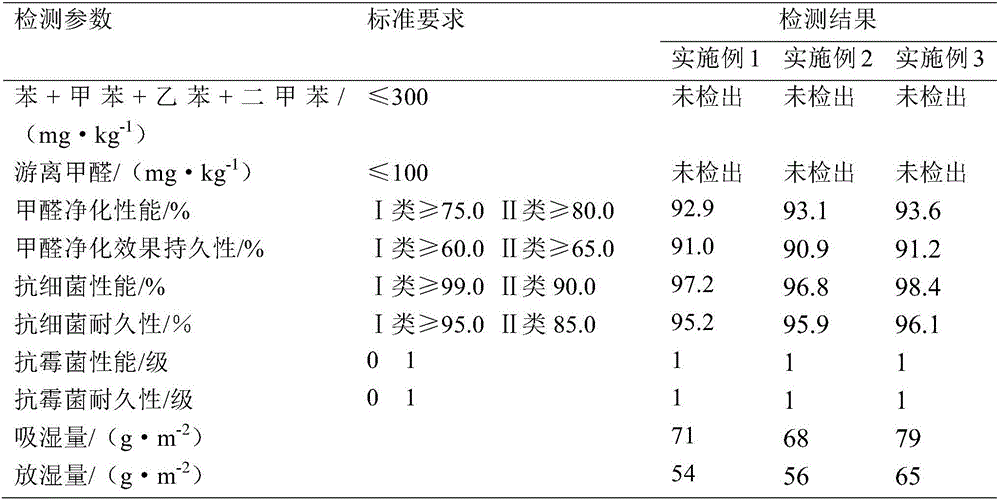

Embodiment 1

[0028] Example 1 Preparation of a novel humidity-adjusting, antibacterial, and environmentally friendly diatom mud wall material

[0029] (1) Weigh each raw material according to each quality, put it into a high-speed disperser at a speed of 900r / min, stir for 2min, and mix evenly to obtain a mixed dry powder material:

[0030] Diatomite 50kg, quartz sand 5kg, wollastonite powder 15kg, redispersible latex powder 5kg, sodium hexametaphosphate dispersant 1.5kg, negative ion powder 15kg, carbon fiber 10kg, humidity control agent 10kg, cold catalyst 5kg, graphene 5kg ;

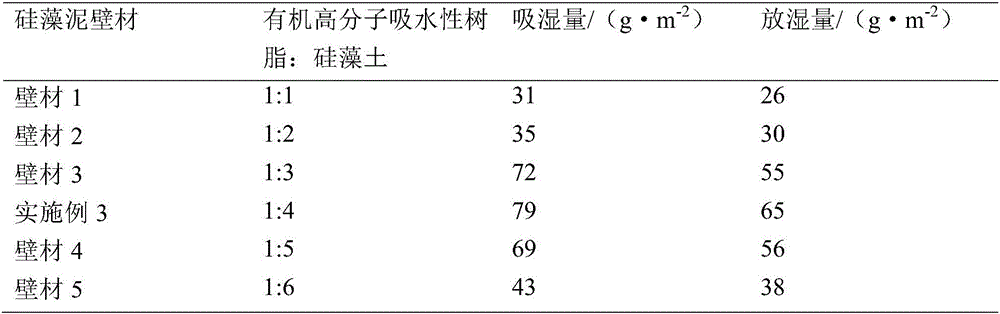

[0031] Wherein, the humidity conditioner is prepared by uniformly mixing organic polymer water-absorbing resin and diatomaceous earth at a mass ratio of 1:3;

[0032] The superabsorbent resin is formed by reacting acrylic acid, acrylamide, crosslinking agent N, N-methylenebisacrylamide through initiator potassium persulfate;

[0033] (2) According to the mass ratio of water and mixed dry powder material of 1:1.3...

Embodiment 2

[0034] Example 2 Preparation of a novel humidity-adjusting, antibacterial, and environmentally friendly diatom mud wall material

[0035] (1) Weigh each raw material according to each quality, put it into a high-speed disperser at a speed of 1200r / min, stir for 2-3min, and mix evenly to obtain a mixed dry powder material:

[0036] Diatomite 60kg, quartz sand 15kg, wollastonite powder 25kg, redispersible latex powder 10kg, sodium hexametaphosphate dispersant 2kg, negative ion powder 20kg, carbon fiber 15kg, humidity control agent 25kg, cold catalyst 10kg, graphene 10kg;

[0037] Wherein, the humidity conditioner is prepared by uniformly mixing organic polymer water-absorbing resin and diatomaceous earth at a mass ratio of 1:5;

[0038] The superabsorbent resin is formed by reacting acrylic acid, acrylamide, crosslinking agent N, N-methylenebisacrylamide through initiator potassium persulfate;

[0039] (2) According to the mass ratio of water and mixed dry powder material of 1:...

Embodiment 3

[0040] Example 3 Preparation of a novel humidity-adjusting, antibacterial, and environmentally friendly diatom mud wall material

[0041] (1) Weigh each raw material according to each quality, put it into a high-speed disperser at a speed of 1000r / min, stir for 2.5min, and mix evenly to obtain a mixed dry powder material:

[0042] Diatomite 55kg, quartz sand 10kg, wollastonite powder 20kg, redispersible latex powder 7.5kg, sodium hexametaphosphate dispersant 1.75kg, negative ion powder 17kg, carbon fiber 13kg, humidity control agent 17kg, cold catalyst 8kg, graphene 8kg;

[0043] Wherein, the humidity-conditioning agent is prepared by uniformly mixing organic polymer water-absorbing resin and diatomaceous earth at a mass ratio of 1:4;

[0044]The superabsorbent resin is formed by reacting acrylic acid, acrylamide, crosslinking agent N, N-methylenebisacrylamide through initiator potassium persulfate;

[0045] (2) According to the mass ratio of water and mixed dry powder mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com