Cleaning agent for removing emulsion deposits and preparation method and application of cleaning agent

A sediment and cleaning agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex process, difficult operation, and consumption of cleaning agents, and achieve simple preparation process, good stability, and environmentally friendly formula Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

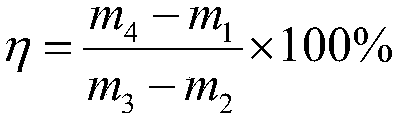

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a cleaning agent for removing latex deposits, which is prepared by the following method:

[0049] 30 kg of ethylene glycol monobutyl ether, 40 kg of didecyl dimethyl ammonium chloride, 1 kg of polyetheramine (D230) with a molecular weight of 230, 5 kg of oleic acid imidazoline corrosion inhibitor, 5 kg of poly Dimethylsiloxane (PMX-200) defoamer, 19 kilograms of sodium bicarbonate solution with a mass concentration of 0.5% were placed in a reaction kettle, and stirred at 100 r / min for 15 minutes at 20 ° C to obtain this example cleaning agent.

Embodiment 2

[0051] This embodiment provides a cleaning agent for removing latex deposits, which is prepared by the following method:

[0052] 20 kg of ethylene glycol dibutyl ether, 20 kg of didecyl dimethyl ammonium chloride, 10 kg of didodecyl dimethyl ammonium bromide, 0.5 kg of polyether amine (D2000) with a molecular weight of 2000 , 10 kilograms of castor oil alkyd amide corrosion inhibitor, 10 kilograms of polyoxyethylene and polyoxypropylene block copolymer (GPE30) defoamer, 29.5 kilograms of mass concentration are 0.5% sodium chloride solution placed in the reactor , and stirred at 600 r / min for 10 min under the condition of 22° C. to obtain the cleaning agent of this embodiment.

Embodiment 3

[0054] This embodiment provides a cleaning agent for removing latex deposits, which is prepared by the following method:

[0055] With 30 kilograms of diethylene glycol monobutyl ether, 30 kilograms of didecyl dimethyl ammonium chloride, 5 kilograms of molecular weight polyetheramine (D400) of 400, 2 kilograms of coconut oil alkylamine corrosion inhibitor, 3 Kilograms of polydimethylsiloxane (PMX-200) defoamer, 30 kilograms of mass concentration are 0.5% sodium carbonate solution placed in the reactor, stirred at 500r / min for 10min under the condition of 24°C to obtain the present implementation Examples of cleaning agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com