Rubber insole and preparation method thereof

An insole and rubber technology, applied in the field of rubber insole and its preparation, can solve the problems of easy occurrence of foot odor, foot sweat, insufficient wearing comfort, poor rebound effect, etc., and achieves light weight, good air permeability, and environmentally friendly formula Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

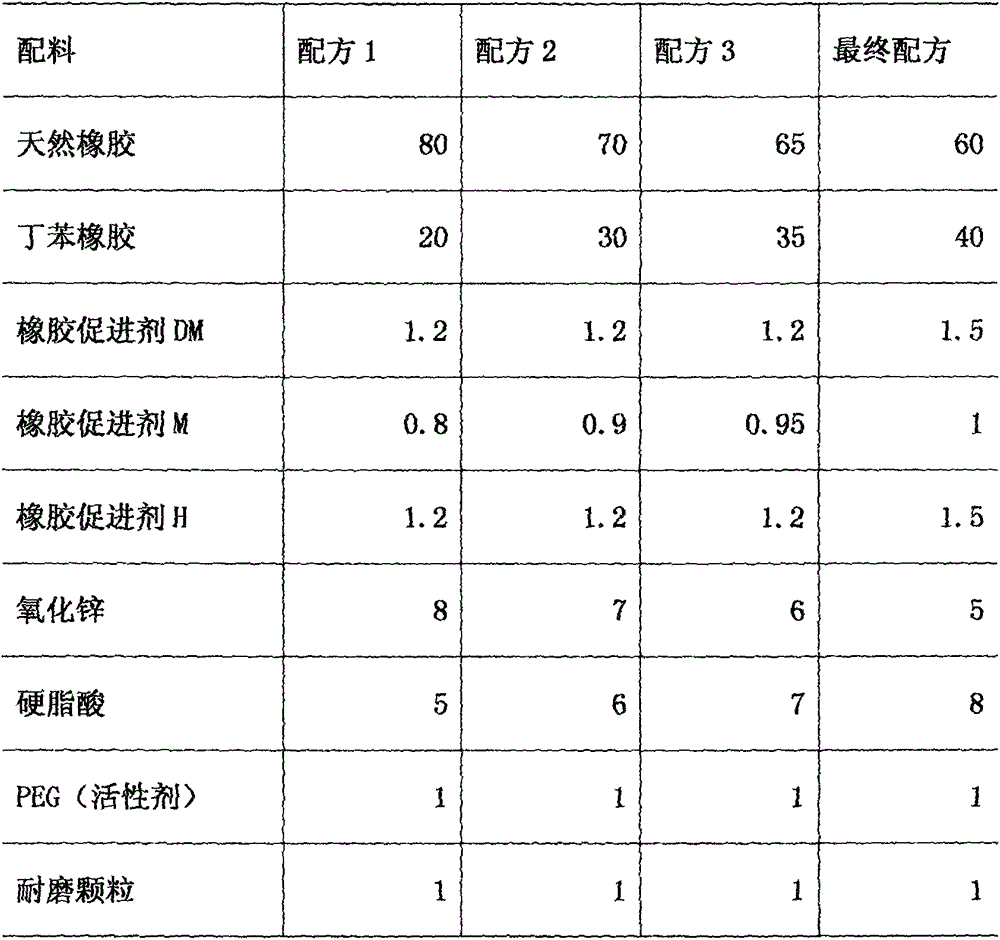

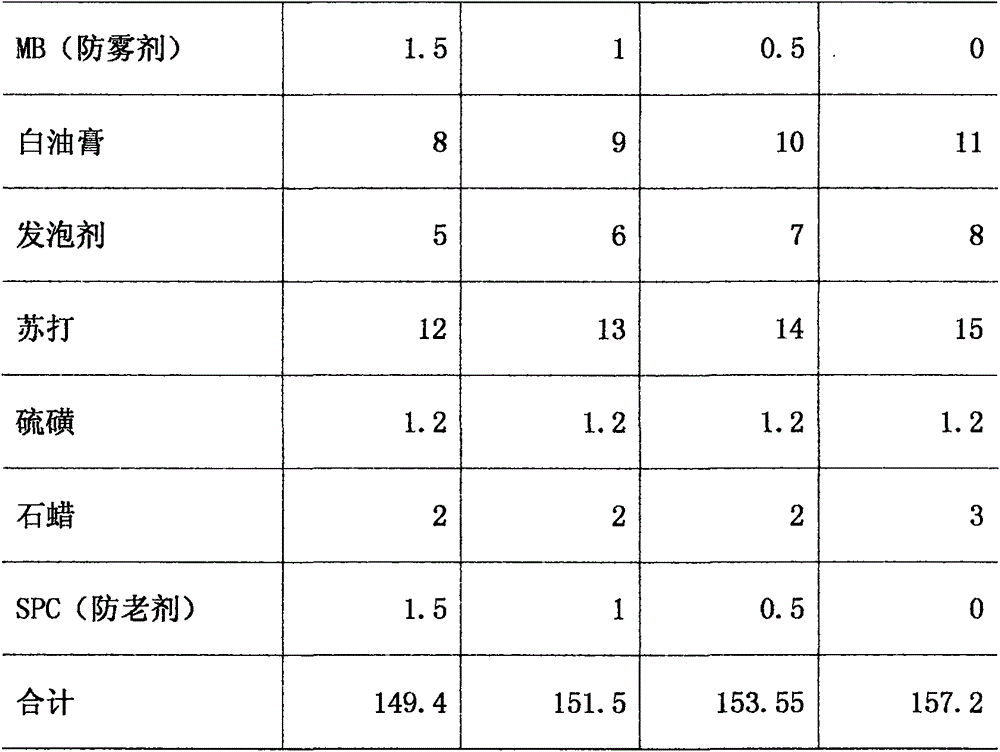

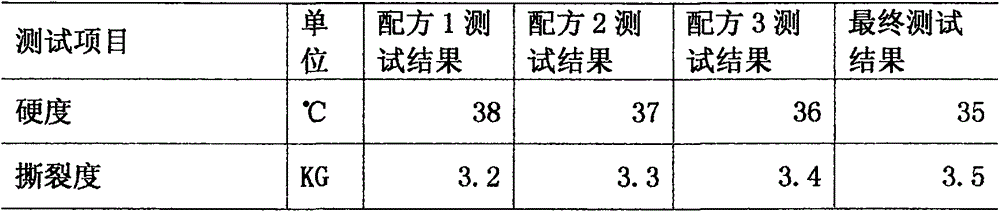

[0017] A rubber insole and a preparation method thereof, characterized in that: the rubber insole is formulated according to the following components by weight

[0018] Natural rubber 60-80, styrene-butadiene rubber 20-40, rubber accelerator DM1.2-1.5, rubber accelerator M0.8-1, rubber accelerator H1.2-1.5, zinc oxide 5-8, stearic acid 5 -8, PEG active agent 1, wear-resistant particles 1, MB anti-fog agent 0-1.5, white ointment 8-11, foaming agent 5-8, soda 12-15, sulfur 1.2, paraffin wax 2-3, SPC anti-aging Agent 0-1.5.

[0019] A rubber insole and a preparation method thereof, characterized in that: comprising the following process steps

[0020] (5) Prepare foamed rubber sheet: put the sole raw material of each weight part described in the formula into a rubber mixer and knead for 30-35min to obtain foamed rubber sheet;

[0021] (6) Prepare upper mold and bottom mold;

[0022] (7) Put the rubber foam sheet prepared in step (1) into the bottom mold, press the upper mold t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com