Low-heat polyurethane grouting reinforcement material

A reinforcement material, polyurethane technology, applied in the field of low-heat two-component polyurethane grouting reinforcement materials, can solve problems such as catalyst failure, high reaction temperature, underground rescue failure, etc., to reduce overall cost, lower reaction temperature rise, and easy to obtain sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of component A: Weigh 60 parts by weight of polymeric MDI, 20 parts by weight of palm oil, and 20 parts by weight of oleic acid ester, add them in order to a common single-layer stirred tank, stir for 20 minutes at normal temperature and pressure, and then directly pack Put it into a 25kg / barrel PE drum and seal it for later use.

[0037] Preparation of component B: weigh 22.8 parts by weight of polyether diol, 3.7 parts by weight of polyether triol, 15 parts by weight of polymer polyol POP, 20 parts by weight of castor oil, and 0.2 parts by weight of organic lead Catalyst (lead triacetate), aluminum hydroxide powder of 2 parts by weight, modified graphite powder of 3 parts by weight. Put the above-mentioned ingredients into the ordinary single-layer stirred tank in order, stir for 20 minutes at normal temperature and pressure, and then put them into 25kg / barrel PE barrels and seal them for later use.

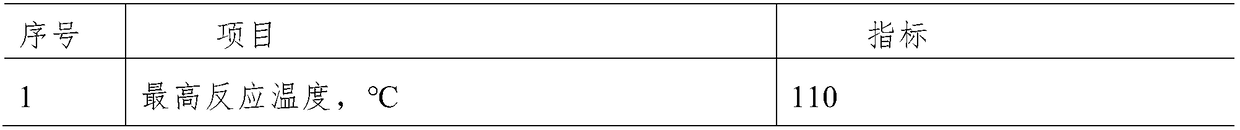

[0038] Samples were prepared and tested according to t...

Embodiment 2

[0044] Preparation of component A: Weigh 70 parts by weight of polymeric MDI, 20 parts by weight of oleic acid ester, and 10 parts by weight of soybean oil, and add them into a common single-layer stirred tank in sequence, stir for 20 minutes at normal temperature and pressure, and then pack directly Put it into a 25kg / barrel PE drum and seal it for later use.

[0045] Preparation of component B: weigh 20 parts by weight of polyether diol, 4 parts by weight of polyether triol, 20 parts by weight of polymer polyol POP, 9.8 parts by weight of soybean oil, 20 parts by weight of epoxy resin soybean oil, 0.2 parts by weight of organic lead catalyst (lead triacetate), 1 part by weight of aluminum hydroxide powder, 1 part by weight of fumed silica, and 3 parts by weight of modified graphite powder. Put the above-mentioned ingredients into the ordinary single-layer stirred tank in order, stir for 20 minutes at normal temperature and pressure, and then put them into 25kg / barrel PE barr...

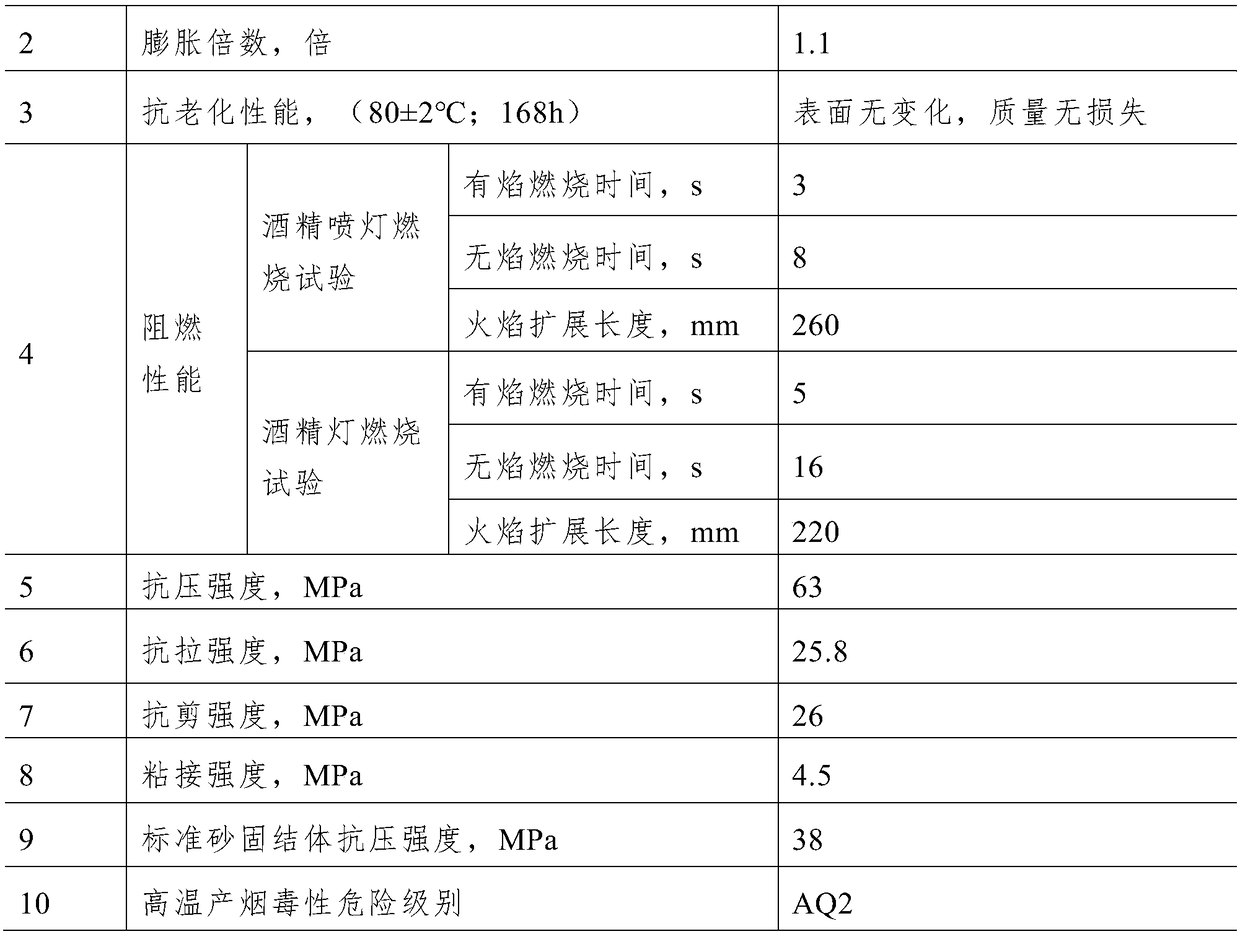

Embodiment 3

[0051] Preparation of component A: Weigh 80 parts by weight of polymeric MDI, 10 parts by weight of corn oil, and 10 parts by weight of oleic acid ester, add them in order to a common single-layer stirred tank, stir at room temperature and pressure for 20 minutes, and then pack directly Put it into a 25kg / barrel PE drum and seal it for later use.

[0052] Preparation of component B: weigh 15 parts by weight of polyether diol, 4 parts by weight of polyether triol, 9.6 parts by weight of polymer polyol POP, 30 parts by weight of castor oil, and 0.2 parts by weight of organic lead Catalyst (lead triacetate), 0.2 parts by weight of organic potassium (potassium tert-butoxide), 2 parts by weight of magnesium oxide powder, 1 part by weight of fumed silica, and 2 parts by weight of silicon carbide powder. Put the above-mentioned ingredients into the ordinary single-layer stirred tank in order, stir for 20 minutes at normal temperature and pressure, and then put them into 25kg / barrel P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com