Water-based thermosetting glass printing ink and preparation method thereof

A printing ink and thermosetting technology, applied in the field of water-based thermosetting glass printing ink and its preparation, can solve the problems of affecting paint film performance, poor adhesion, high glass transition temperature, achieve water resistance and wear resistance, meet industrial production, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

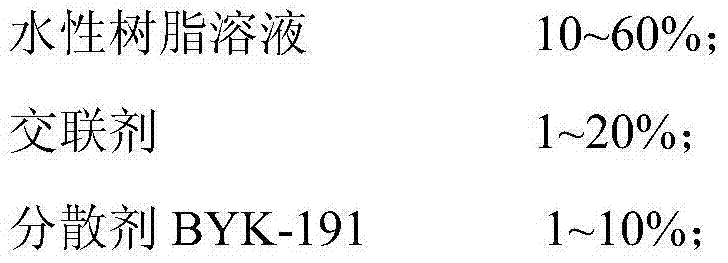

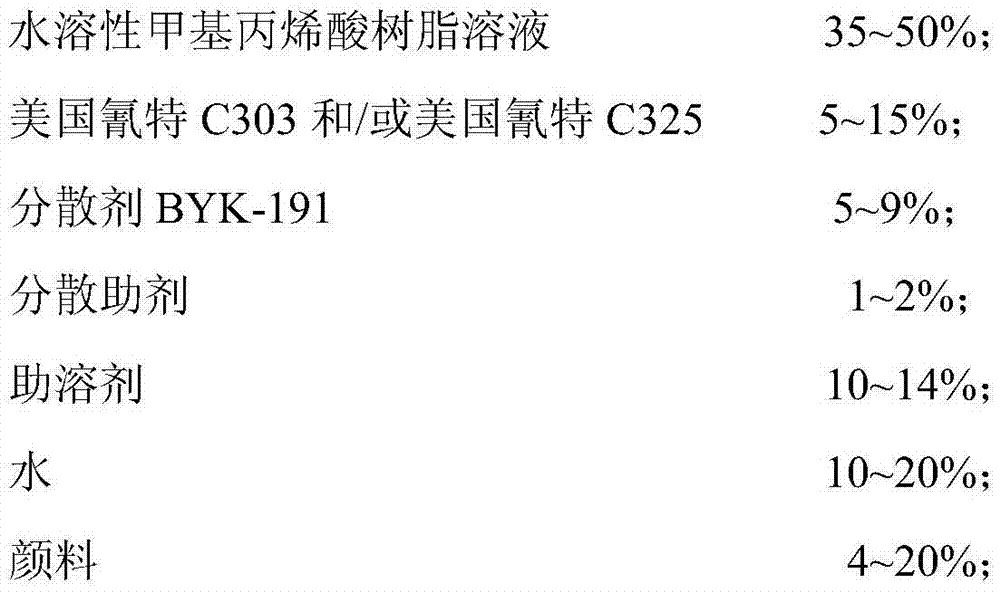

[0025] According to the following formula composition, the water-based thermosetting glass printing ink of the present invention is prepared: the water-based resin solution (about 70% of the total mass of the water-based resin solution is added first), mixed with the dispersant BYK-191, auxiliary agents and pigments, and added to the container, Obtain a slurry with a solid particle size of no more than 20 microns in the solution through high-speed shear dispersion; then add the remaining part of the aqueous resin solution, as well as additives, cross-linking agents and water to the slurry, stir well, and adjust the viscosity to the specified value, and filter through a sieve of 300 mesh or more to obtain water-based thermosetting glass screen printing ink products.

[0026] Formulas 1 to 8 are all calculated as 100 parts.

[0027]

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com