Organic-inorganic compoiste proton exchange film and preparing method

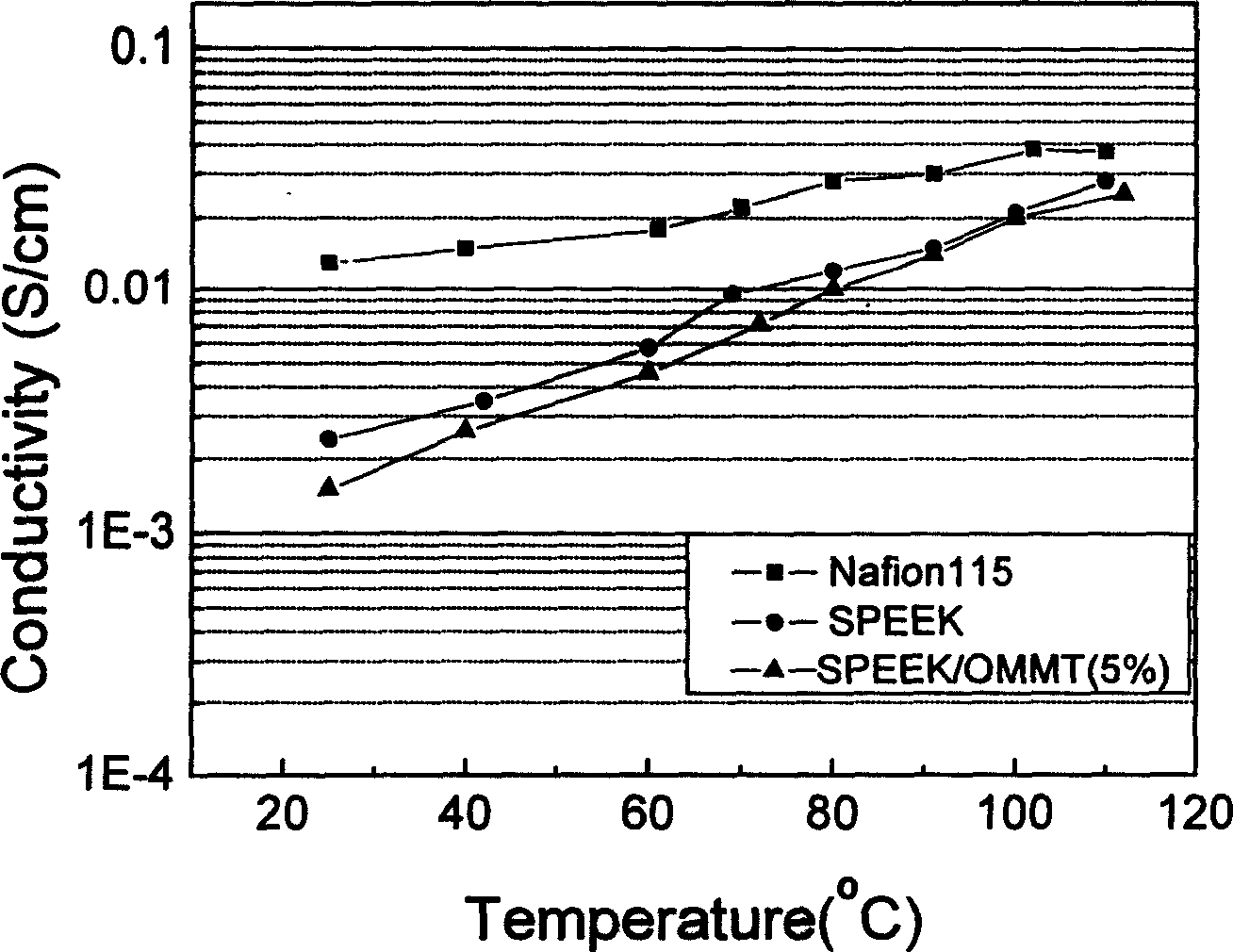

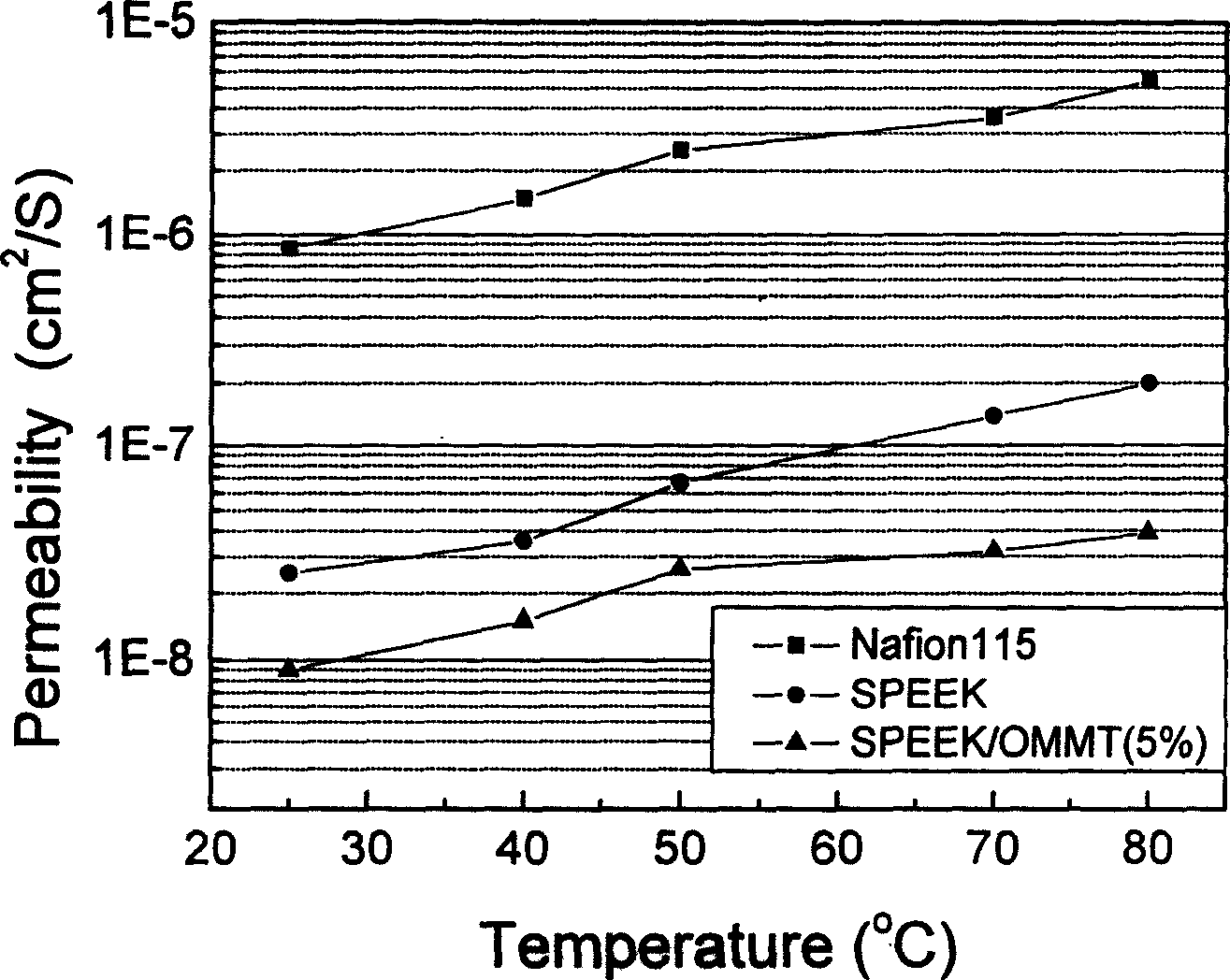

A proton exchange membrane and composite technology, which is used in the field of organic-inorganic composite proton exchange membranes for direct methanol fuel cells and their preparation, can solve the problem of small phase separation between hydrophilic and hydrophobic phases, changes in the three-dimensional size of the membrane, and the Mechanical strength reduction and other problems, to achieve the effects of excellent alcohol resistance, narrow proton channel, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Sulfonation of polymer: in parts by weight, dissolve 1 part of polyetherketone (PEEK) pellets in 50 parts by weight of concentrated sulfuric acid with a concentration of 95% to 98%, stir vigorously at 20°C, and continue After sulfonation for 48 hours, the reaction solution was poured into ice water, the volume of ice water was at least 5 times that of the reaction solution, the product was filtered, washed repeatedly with distilled water until the pH was neutral, and finally vacuum-dried at 60°C for 24 hours to obtain Sulfonated polymers;

[0023] (2) Organic modification of montmorillonite: disperse montmorillonite (MMT) in water, make a suspension with a concentration of 5% by weight, stir vigorously for 1 hour, let it stand for swelling for 24 hours, and take the upper suspension solution, and cetyltrimethylammonium chloride was added, the molar ratio of the organic intercalation agent to the metal cation between the montmorillonite sheets was 2:1, stirred and re...

Embodiment 2

[0030] (1) Sulfonation of polymers: in parts by weight, 1 part of polyphenylene ether pellets was dissolved in 30 parts by weight of concentrated sulfuric acid with a concentration of 95-98%, vigorously stirred at 50°C, and continuously sulfonated for 10 After 1 hour, pour the reaction solution into ice water, the volume of ice water is at least 5 times that of the reaction solution. After the product is filtered, it is washed repeatedly with distilled water until the pH is neutral, and finally vacuum-dried at 60°C for 24 hours to obtain sulfonated polymer thing;

[0031] (2) Organic modification of montmorillonite: disperse montmorillonite (MMT) in water, make a suspension with a concentration of 10% by weight, stir vigorously for 1 hour, let it stand for swelling for 24 hours, and take the upper suspension solution, and dodecyltrimethylammonium chloride was added, the molar ratio of the organic intercalation agent to the metal cation between the montmorillonite sheets was 1:...

Embodiment 3

[0036] (1) Sulfonation of polymers: in parts by weight, dissolve 1 part of polyphenylene sulfide pellets in 40 parts by weight of concentrated sulfuric acid with a concentration of 95-98%, stir vigorously at 30°C, and continue sulfonation After 20 hours, pour the reaction solution into ice water. The volume of ice water is at least 5 times that of the reaction solution. After the product is filtered, it is washed repeatedly with distilled water until the pH is neutral. Finally, it is vacuum-dried at 60°C for 24 hours to obtain the sulfonated polymer;

[0037] (2) Organic modification of montmorillonite: disperse montmorillonite (MMT) in water, make a suspension with a concentration of 10% by weight, stir vigorously for 1 hour, let it stand for swelling for 24 hours, and take the upper suspension solution, and dodecyltrimethylammonium chloride was added, the molar ratio of the organic intercalation agent to the metal cation between the montmorillonite sheets was 1.5:1, stirred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com