Patents

Literature

41 results about "Stripping membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stripping the membranes is a way to induce labor. It involves your doctor sweeping their (gloved) finger between the thin membranes of the amniotic sac in your uterus. This motion helps separate the sac. It stimulates prostaglandins, compounds that act like hormones and can control certain processes in the body.

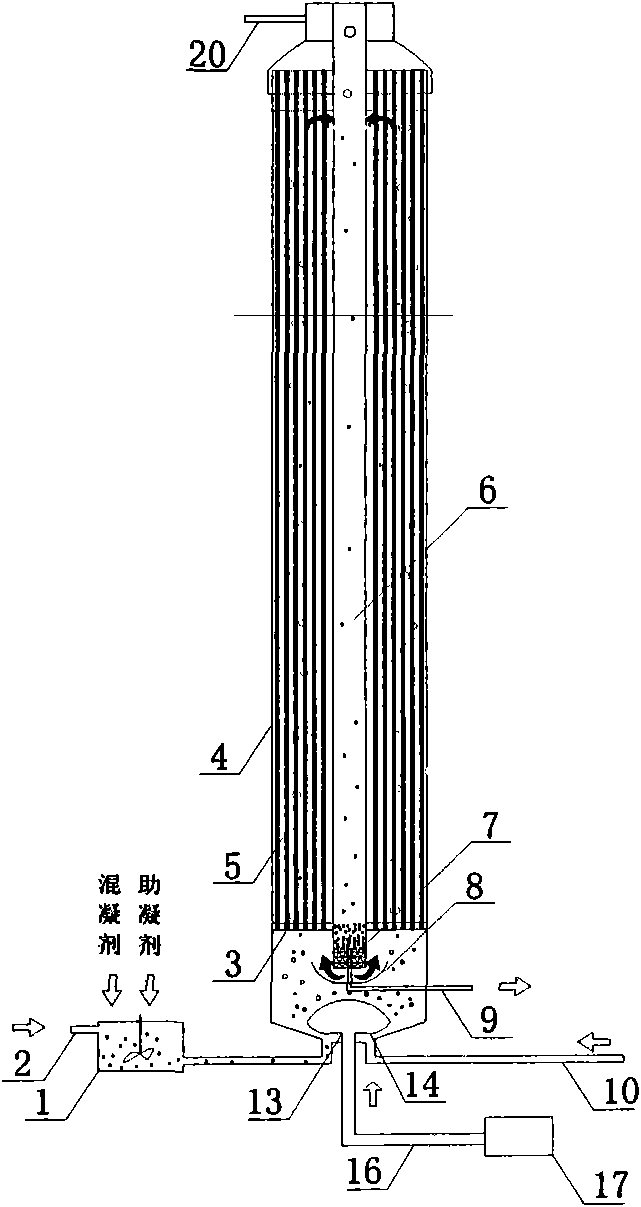

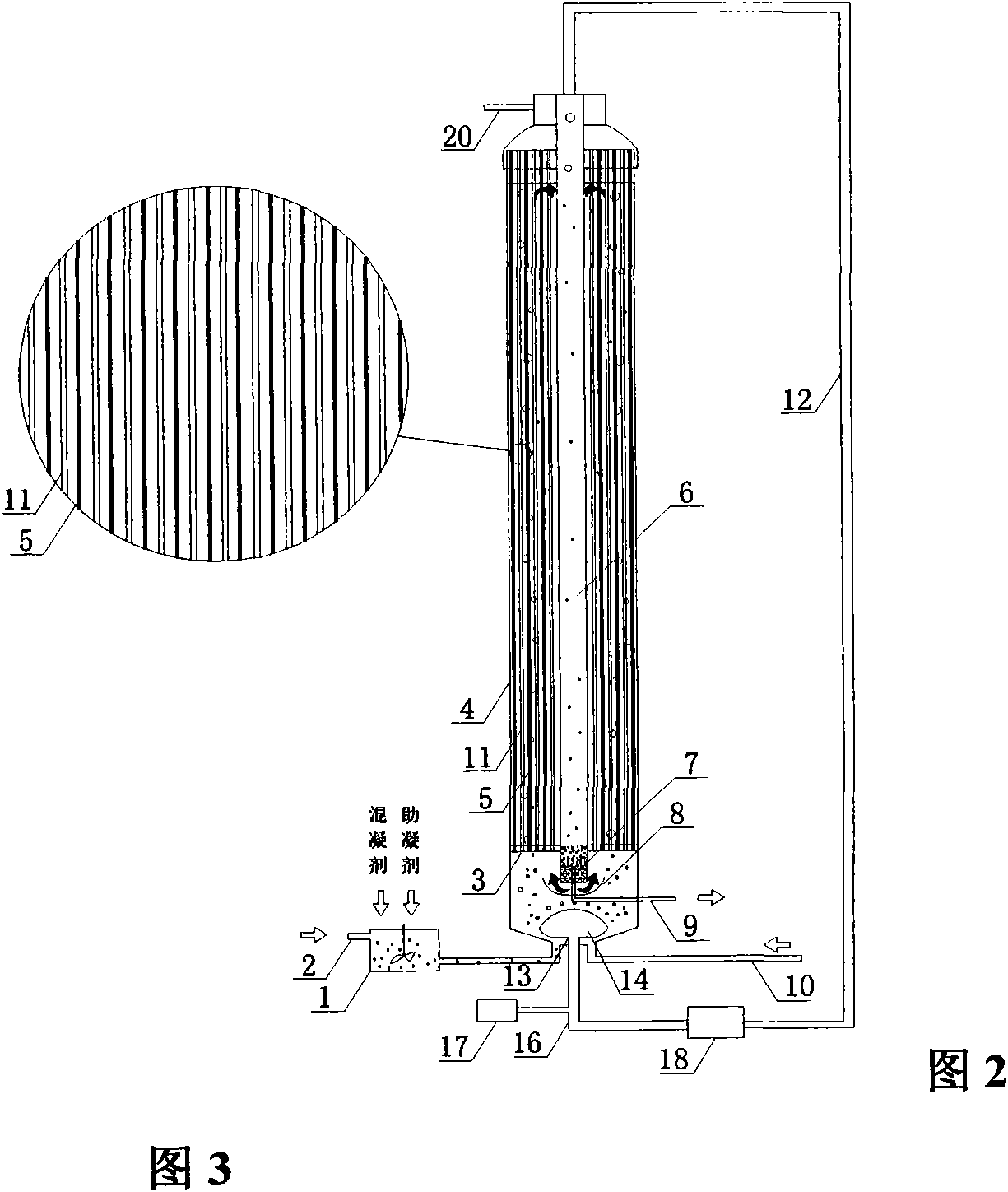

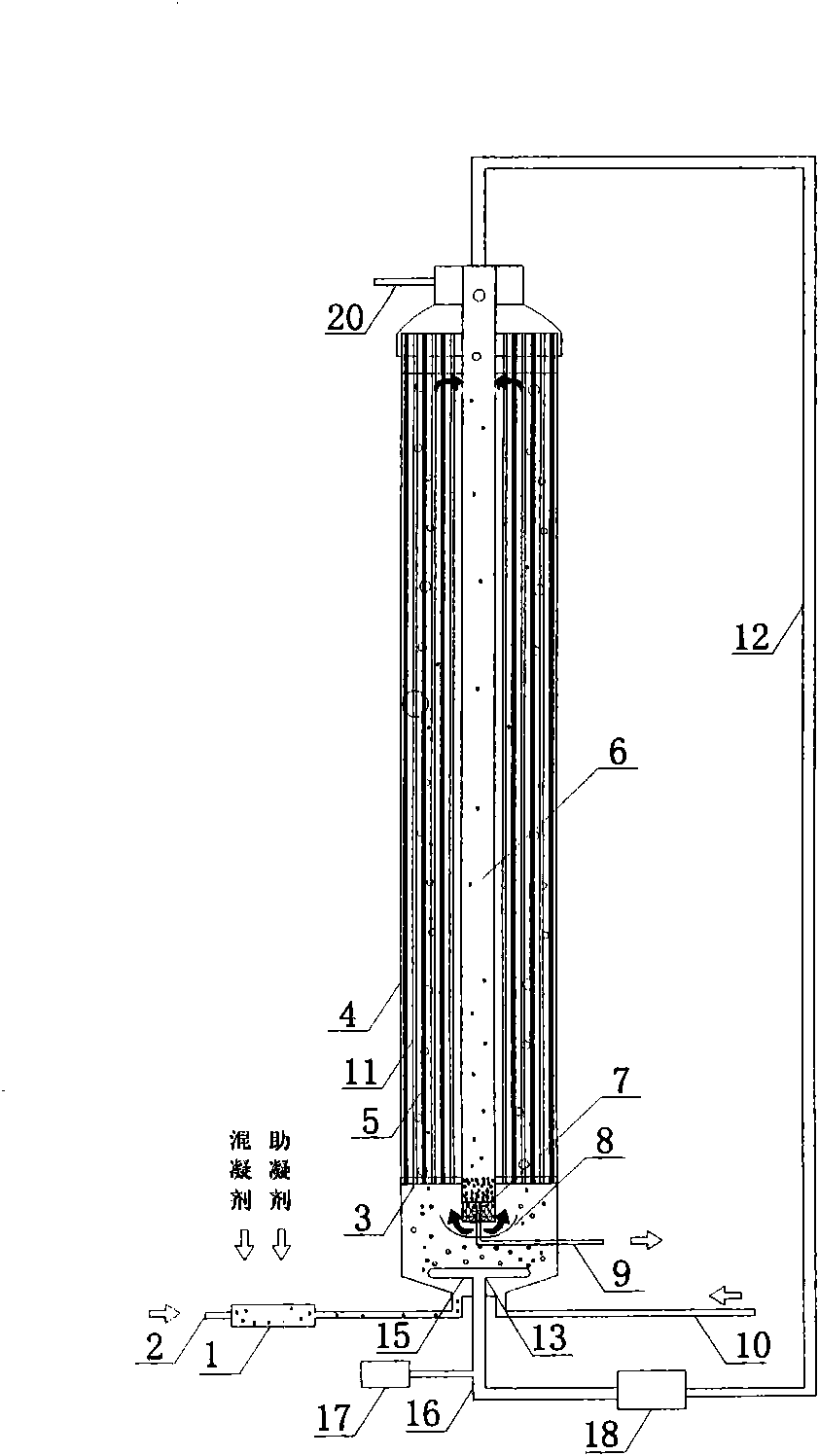

Enhanced coagulation-gas stripping-membrane integration method and device for lightening membrane pollution

InactiveCN101774731AReduce cloggingImprove processing efficiencyTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationEngineering

The invention discloses an enhanced coagulation-gas stripping-membrane integration method for lightening membrane pollution. In the method, a coagulating agent and a coagulant aid are added into raw water and undergo enhanced coagulation reaction by applying hydraulic condition, and airflow circulation and lift treatment is performed while an external pressure hollow fiber membrane component is used for filtration. The invention also discloses an integration device designed according to the method. Through the technical measures of throwing the coagulating agent and the coagulant aid into the raw water, positioning gas stripping type aeration treatment under the filtering of the external pressure hollow fiber membrane component and the like, the method improves the pollutant removal rate and the water treatment effect, greatly lightens the membrane pollution, saves energy consumption of membrane component operation, prolongs the operating cycle of the membrane component, shortens the cleaning time, reduces the back washing cost, has small occupied area, low investment cost and simple and flexible implementation, is applicable to water treatment for large cities, and is also applicable to vast cities and towns and rural regions with imperfect water treatment process and small treatment scale.

Owner:SICHUAN UNIV

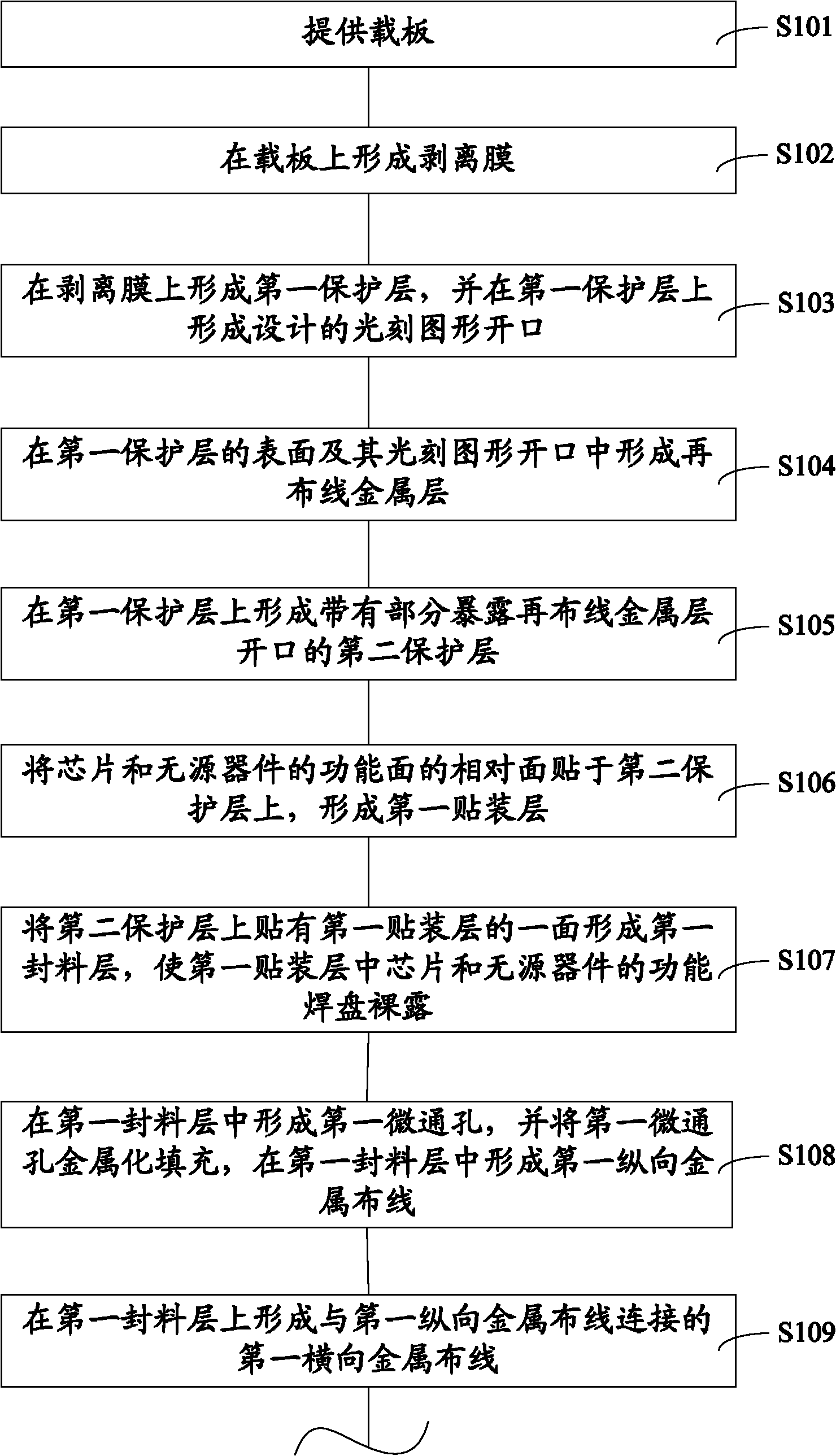

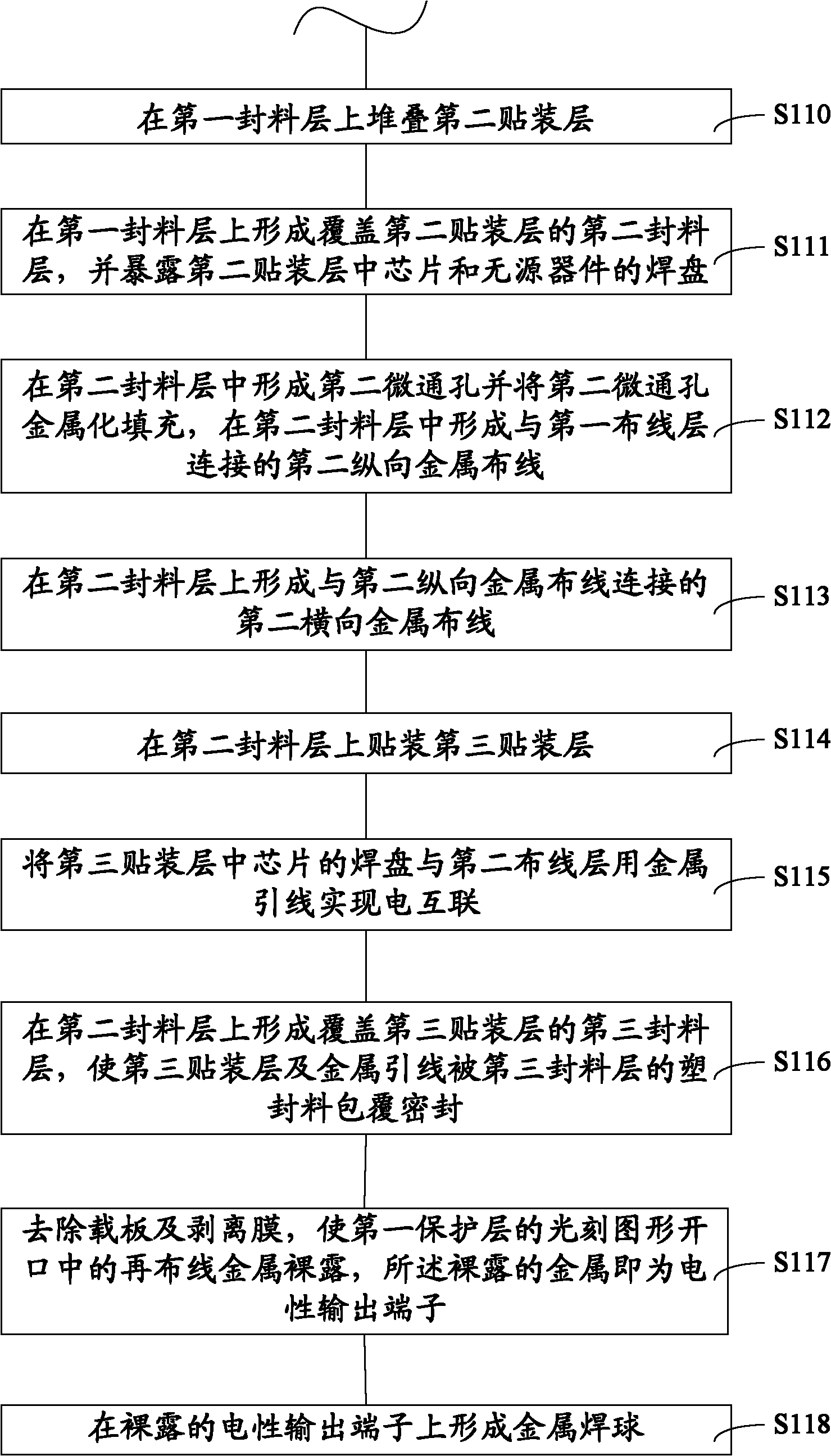

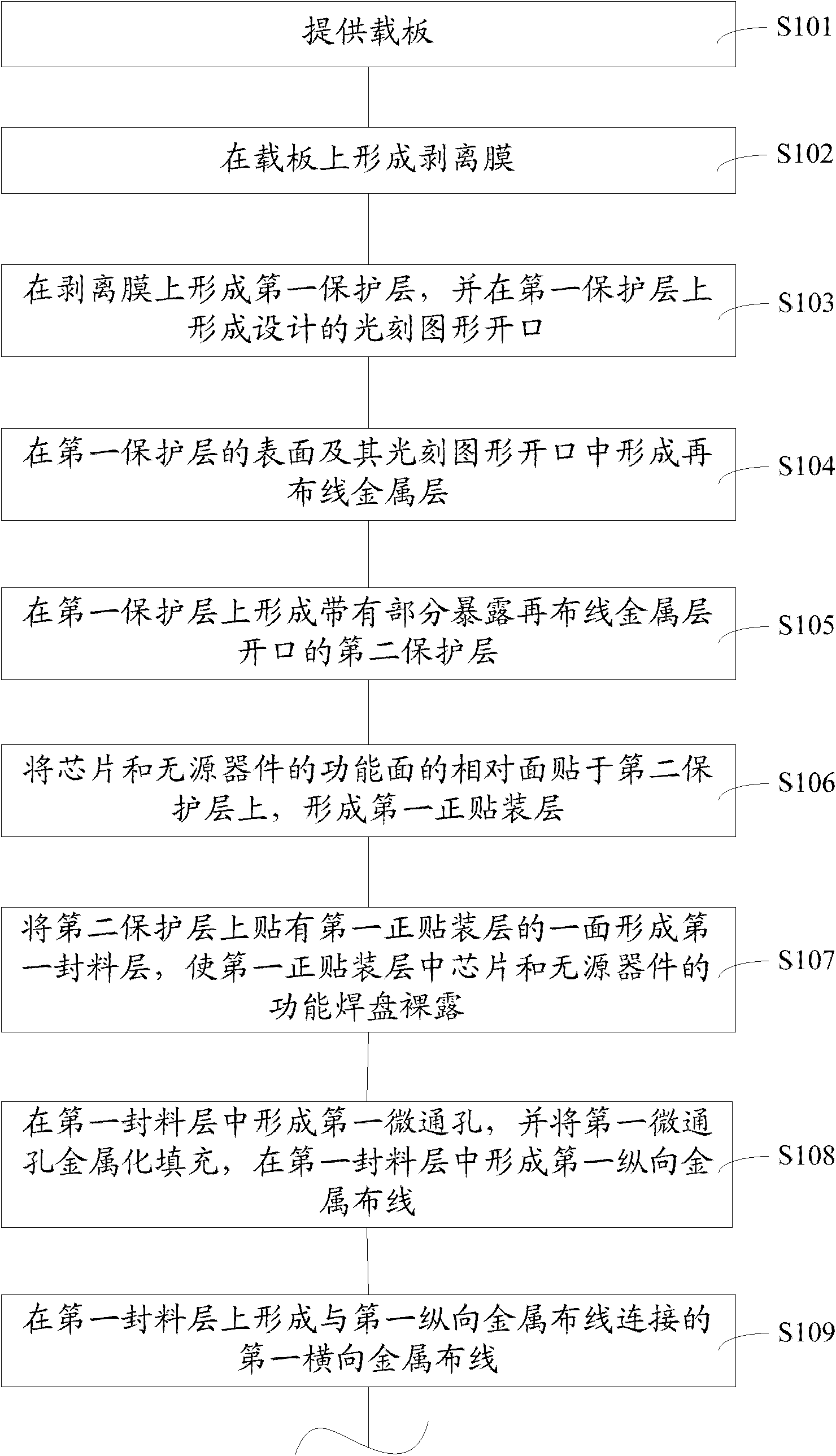

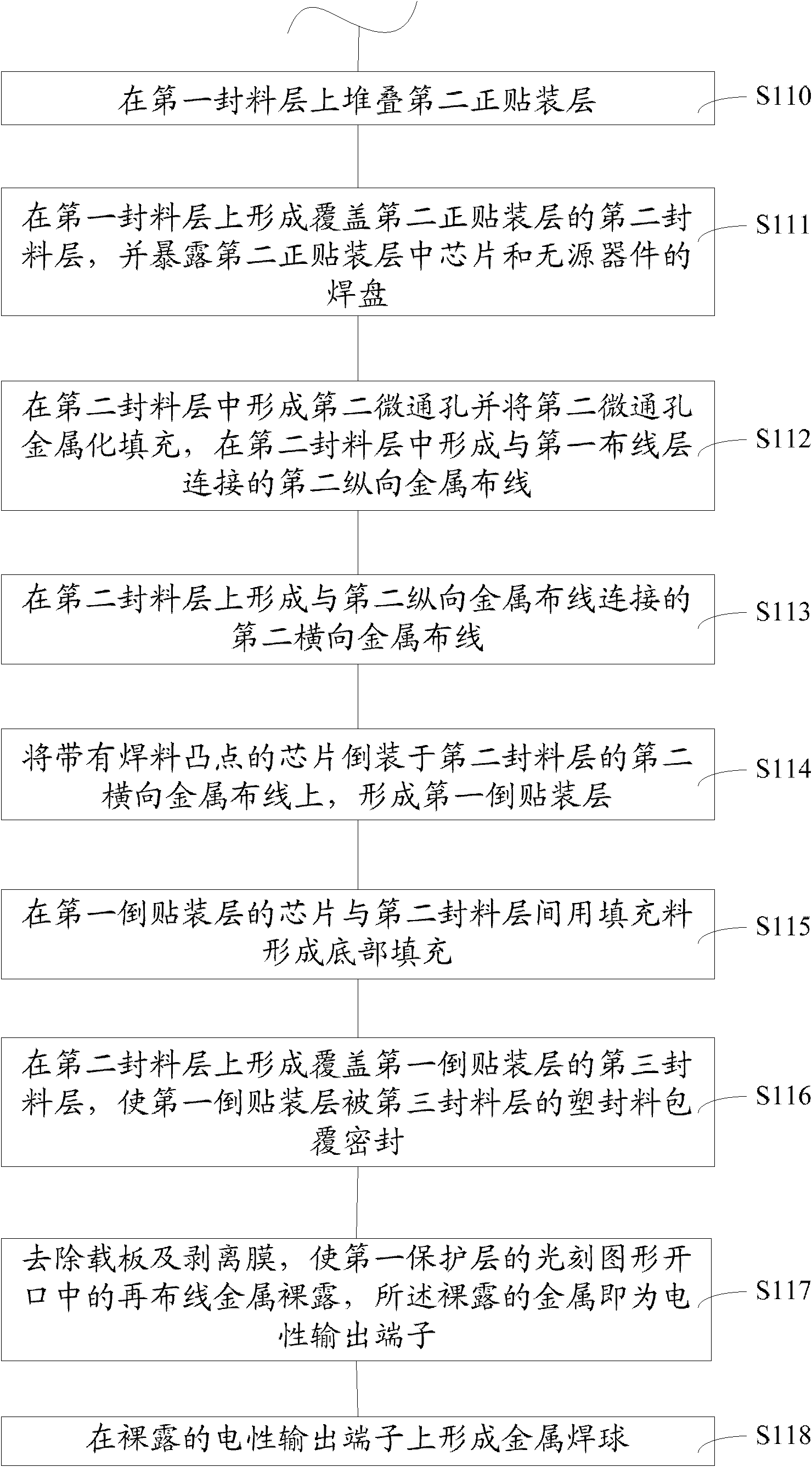

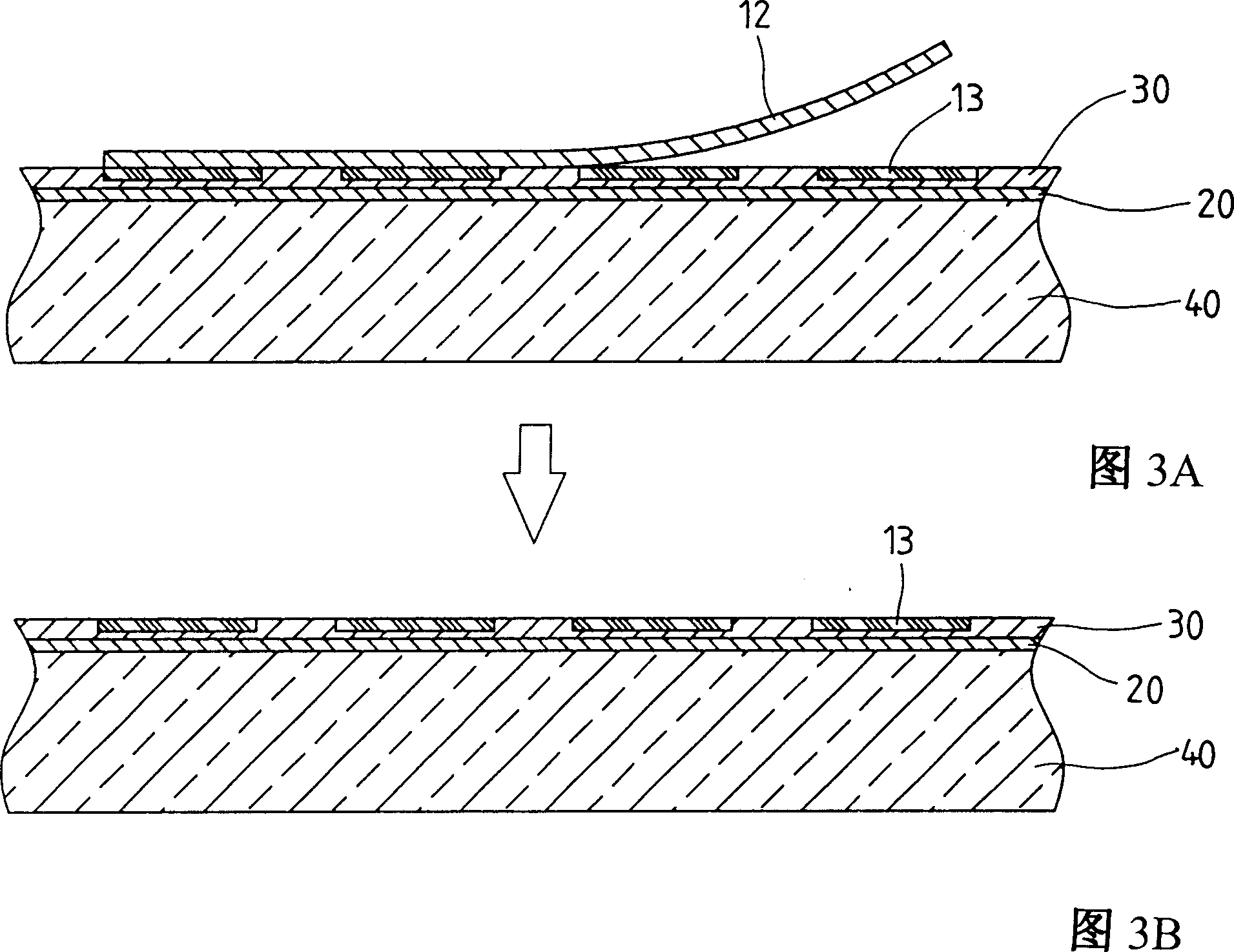

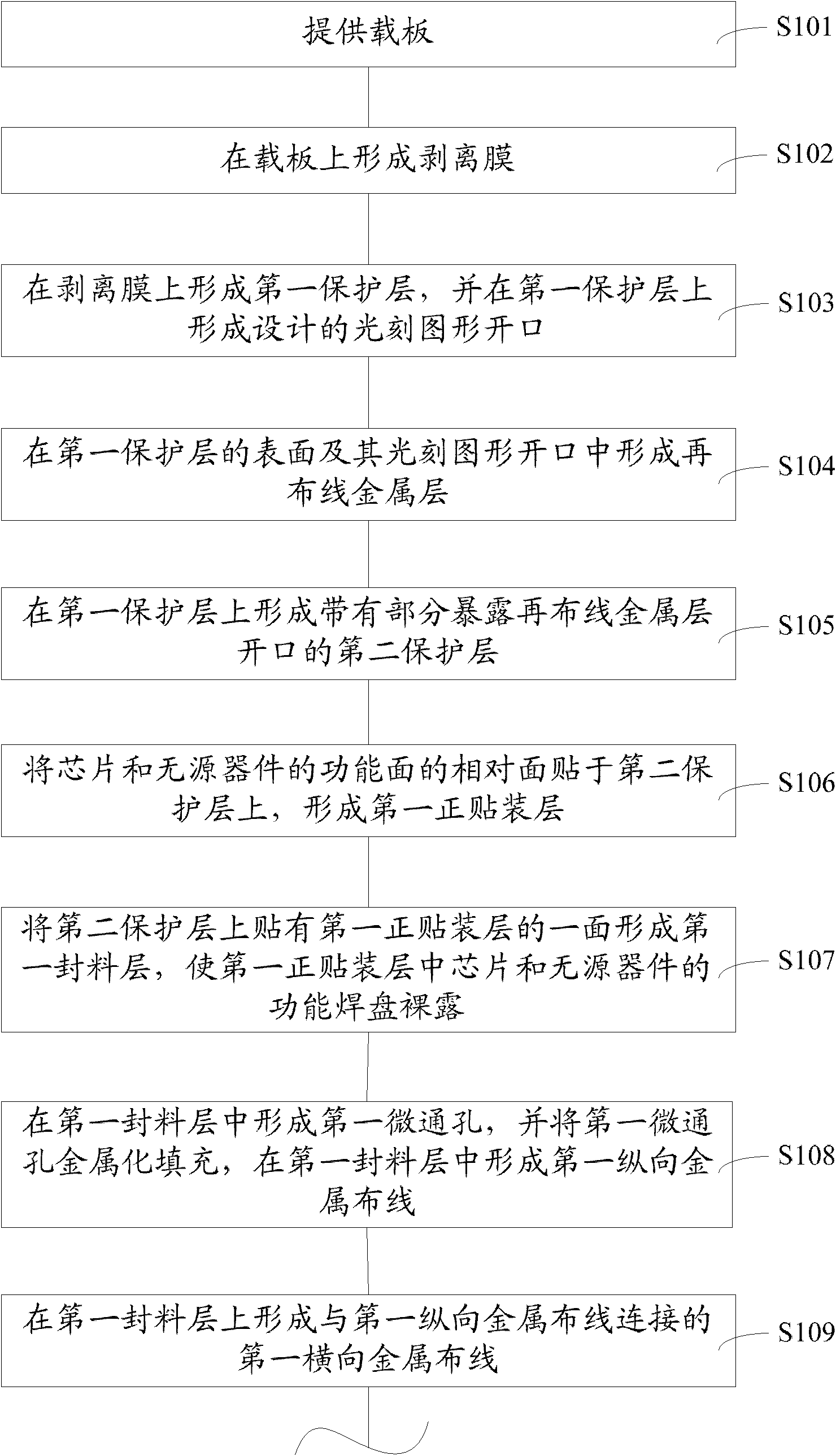

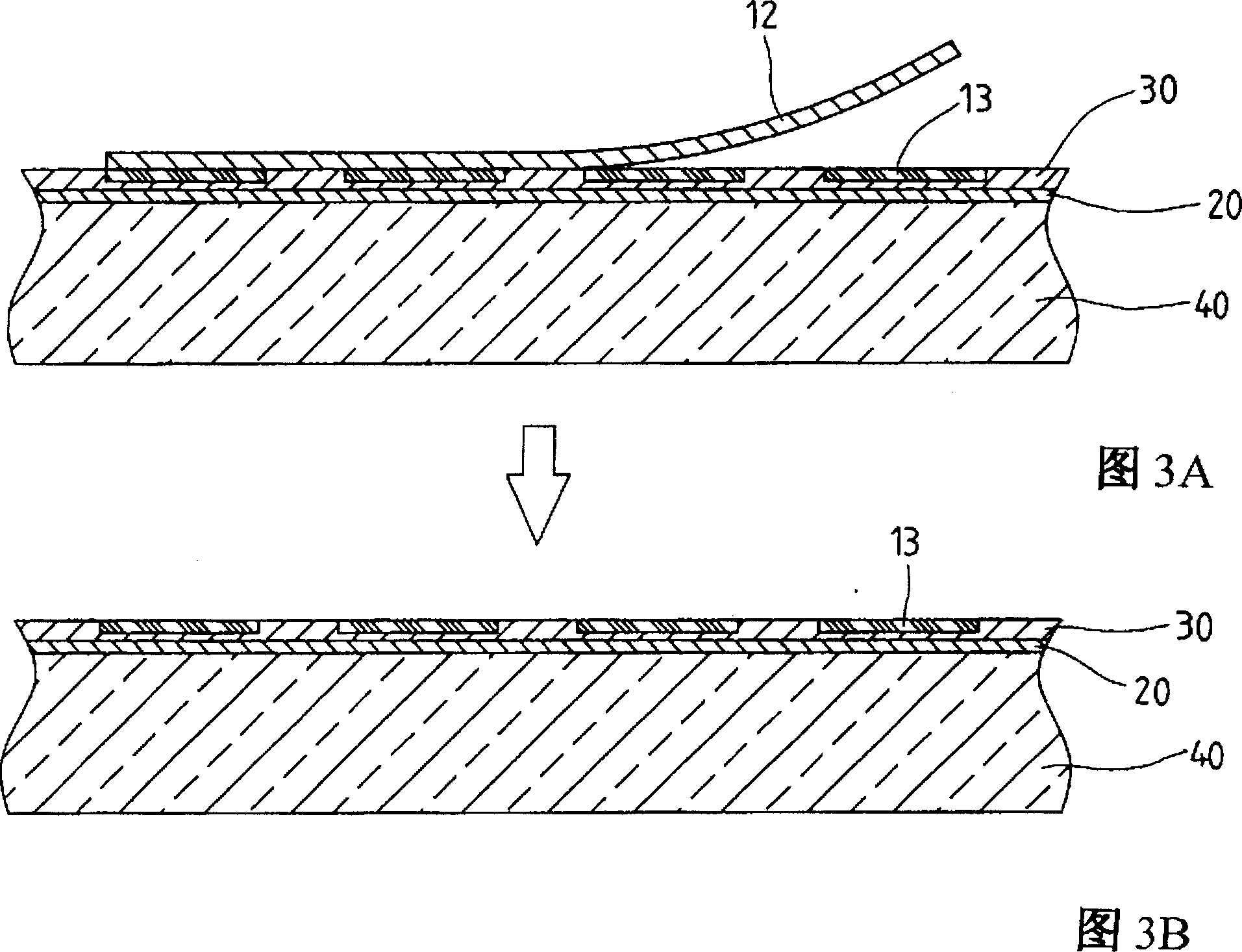

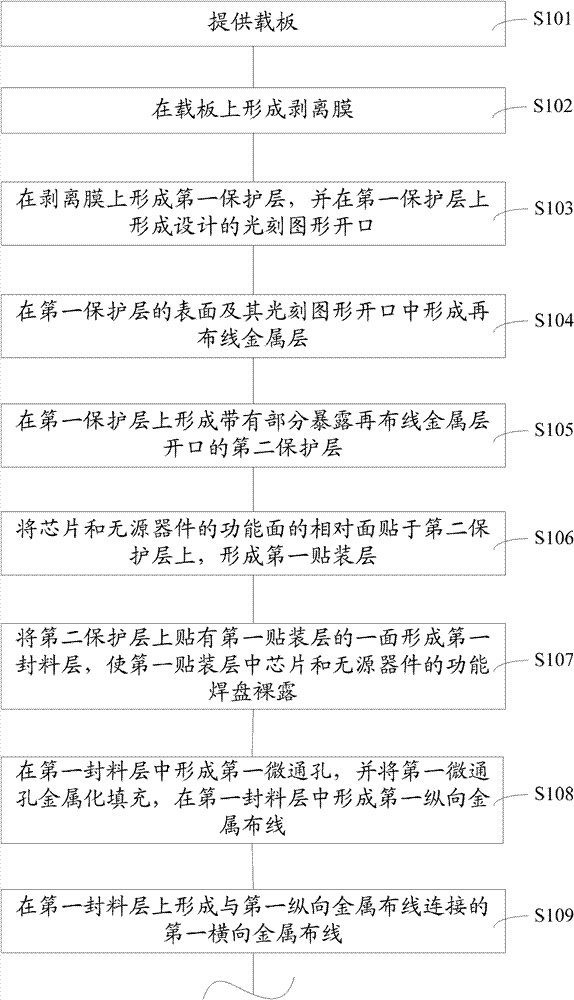

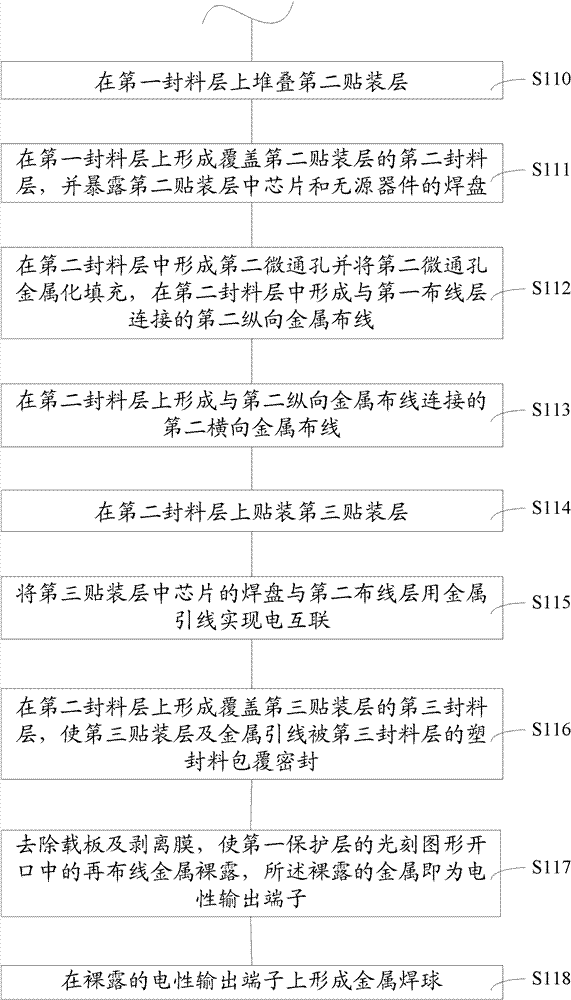

Fan-out system in package (SIP) method

ActiveCN102176418ALess distracting factorsComply with the trend of light, thin and shortSolid-state devicesSemiconductor/solid-state device manufacturingInterference factorSystem in package

The invention relates to a fan-out system in a package (SIP) method. The method comprises the following steps: providing a support plate; forming a stripped membrane on the support plate; forming protective layers on the stripped membrane and forming re-wiring metal layers in the protective layers; forming wiring packaging layers conducted with the re-wiring metal layers on the protective layers and forming wire bonding packaging layers on the wiring packaging layers; and removing the support plate and the stripped membrane to expose the re-wiring metal in the first protective layers and forming metal solder balls on the exposed re-wiring metal, wherein the packaging layers are electrically connected with each other. Compared with the prior art, the method which the invention requests to protect has the following beneficial effects: the final packaged products having the functions of the whole system instead of the functions of the single chip can be formed; the interference factors among the resistors, inductors and chips in the system are reduced; and besides, the more complex multilayer interconnection structure can be formed and higher integration level wafer SIP can be realized.

Owner:NANTONG FUJITSU MICROELECTRONICS

Fan-out high-density packaging method

ActiveCN102157393ALess distracting factorsComply with the trend of light, thin and shortSolid-state devicesSemiconductor/solid-state device manufacturingInterference factorEngineering

The invention relates to a fan-out high-density packaging method, which comprises the following steps of: providing a carrier plate; forming a stripping membrane on the carrier plate; forming protective layers on the stripping membrane; forming a rewiring metal layer in the protective layers; forming wiring packaging layers which are conductive with the rewiring metal layer on the protective layers; forming inversion packaging layers on the wiring packaging layers, wherein the packaging layers are connected electrically and mutually by wiring layers and welding flux salient points; removing the carrier plate and the stripping membrane, so that rewiring metal in a first protective layer is exposed; and forming a metal welded ball on the exposed rewiring metal. Compared with the prior art, the fan-out high-density packaging method has the advantages that: a final packaging product with an integral systemic function instead of a single chip function can be formed, and the resistance and inductance in a system and interference factors among chips are reduced. In addition, a complex multi-layer interconnection structure can be formed, so that the wafer system-level packaging of a higher integration level is realized.

Owner:NANTONG FUJITSU MICROELECTRONICS

Preparation method of superhydrophobic surface of metal zirconium

ActiveCN101941000AExcellent superhydrophobic propertiesMeet actual needsSurface reaction electrolytic coatingPretreated surfacesAnodizingEtching

The invention provides a preparation method of a superhydrophobic surface of a metal zirconium. The method is as follows: firstly, in site building a nano / micro coarse structure on the surface of the metal zirconium through chemical etching, anodizing and ultraphonic strip membranes; and subsequently, carrying out hydrophobic treatment on the surface through low surface energy substances such as self-assembling siloxane and the like, thereby obtaining the superhydrophobic metal zirconium surface. The metal zirconium surface treated by using the method of the invention has good superhydrophobic property, a contact angle with water-drop reaches 157-163 degrees, and a roll angle is less than 3 degrees, thereby meeting the demand of industry fields on the superhydrophobic surface of the metal zirconium. The method of the invention has the characteristics of simple process, convenient operation, low production cost, easy large-scale preparation, industrial production and the like.

Owner:苏州盛泽科技创业园发展有限公司

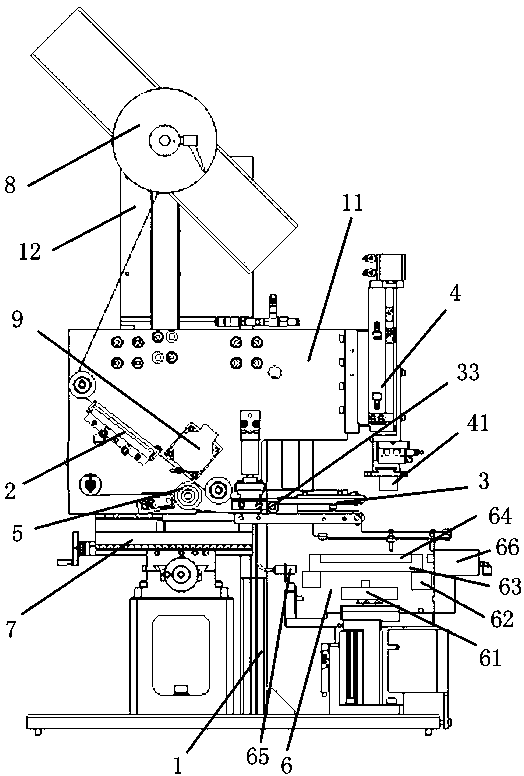

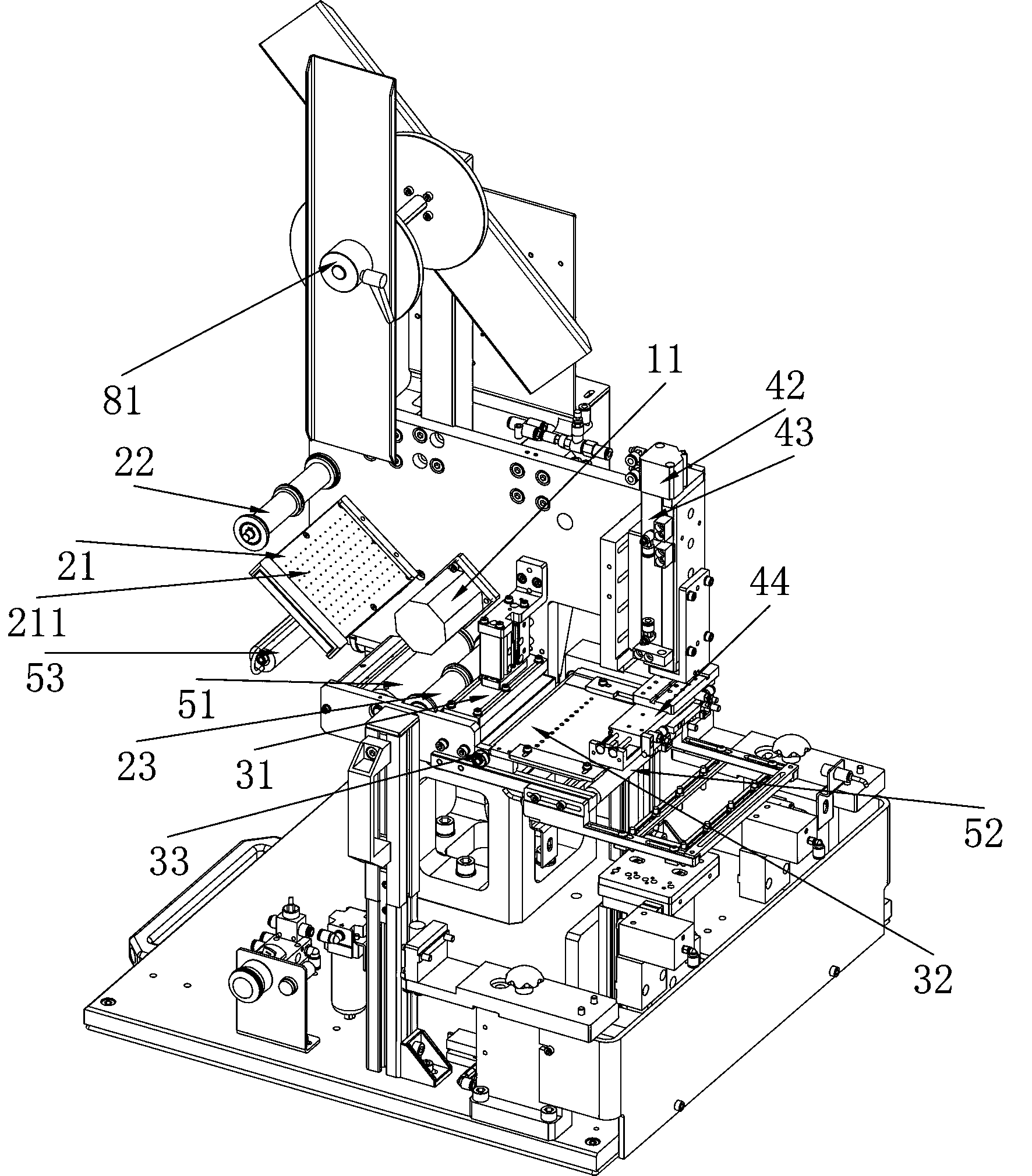

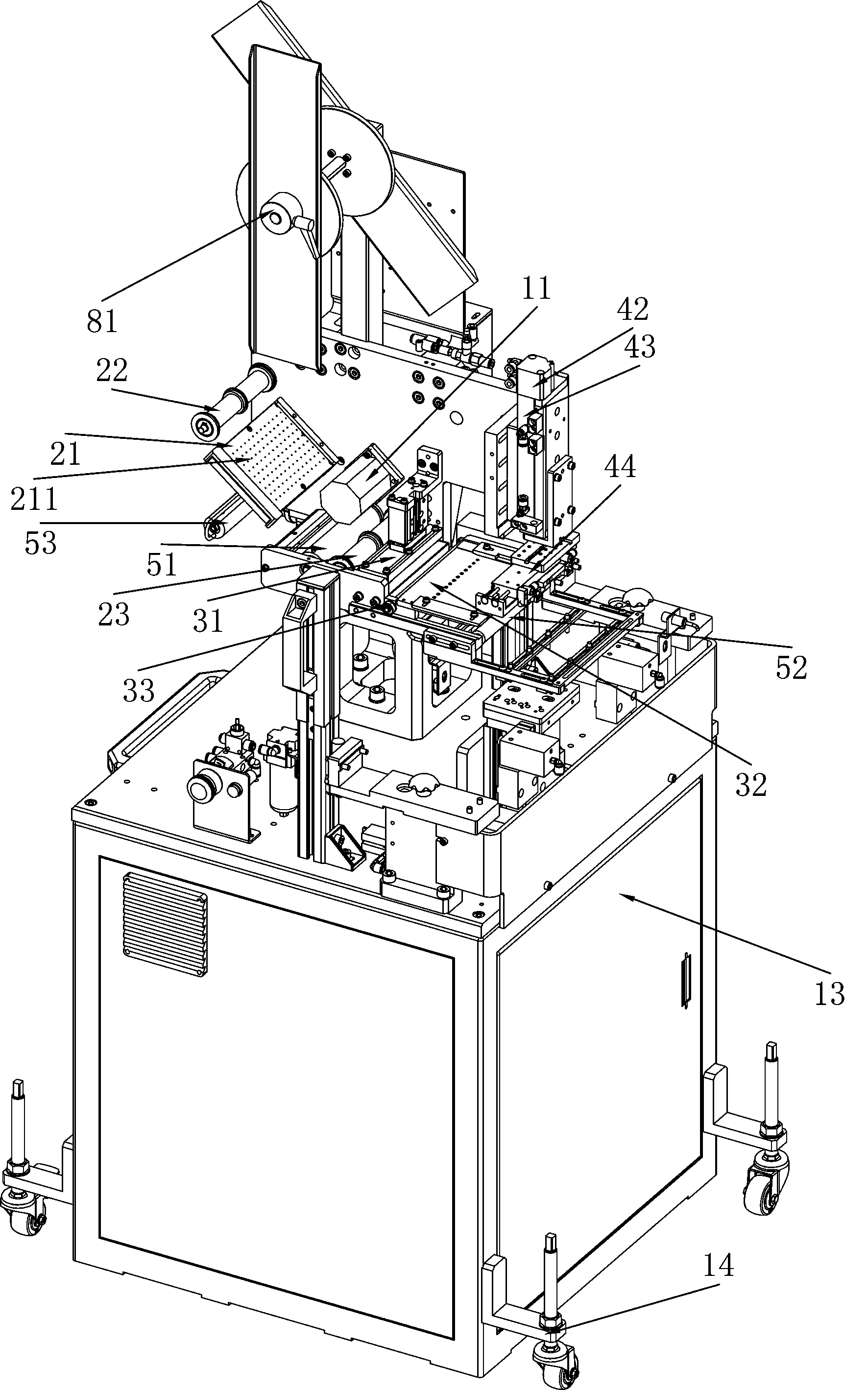

Full-automatic laminator

InactiveCN104309848AIncrease usageReduce dosagePackaging automatic controlArticle deliveryProduction lineStripping membrane

The invention relates to the field of lamination equipment, in particular to a full-automatic laminator. The full-automatic laminator comprises a frame. A feeding mechanism used for conveying material membranes is arranged on the frame. A membrane stripping mechanism used for stripping membranes to be pasted among the material membranes is arranged on the frame and located at the output end of the feeding mechanism. A membrane transfer mechanism used for transferring the stripped membranes to be pasted is arranged on the frame and located at the output end of the membrane stripping mechanism. A waste recovery mechanism used for recovering stripped waste is further arranged on the frame and located at the output end of the membrane stripping mechanism. The frame is further provided with a membrane pasting mechanism used for pasting the membranes to be pasted onto workpieces in cooperation with the transfer mechanism. Compared with manual membrane pasting and membrane pasting through an existing laminator, the full-automatic laminator has the advantages that manual intervention is not needed, manual membrane pasting on a production line is replaced, and the labor cost is lowered; the membrane pasting speed is increased, and the productivity of the production line is improved; the use number of single auxiliary material pieces is reduced; the bad phenomena of deviation, pasting missing, scratches, damage, unevenness (wrinkles) and the like in the manual membrane pasting process are avoided, waste of auxiliary materials is reduced, and the utilization rate of the auxiliary materials is increased.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

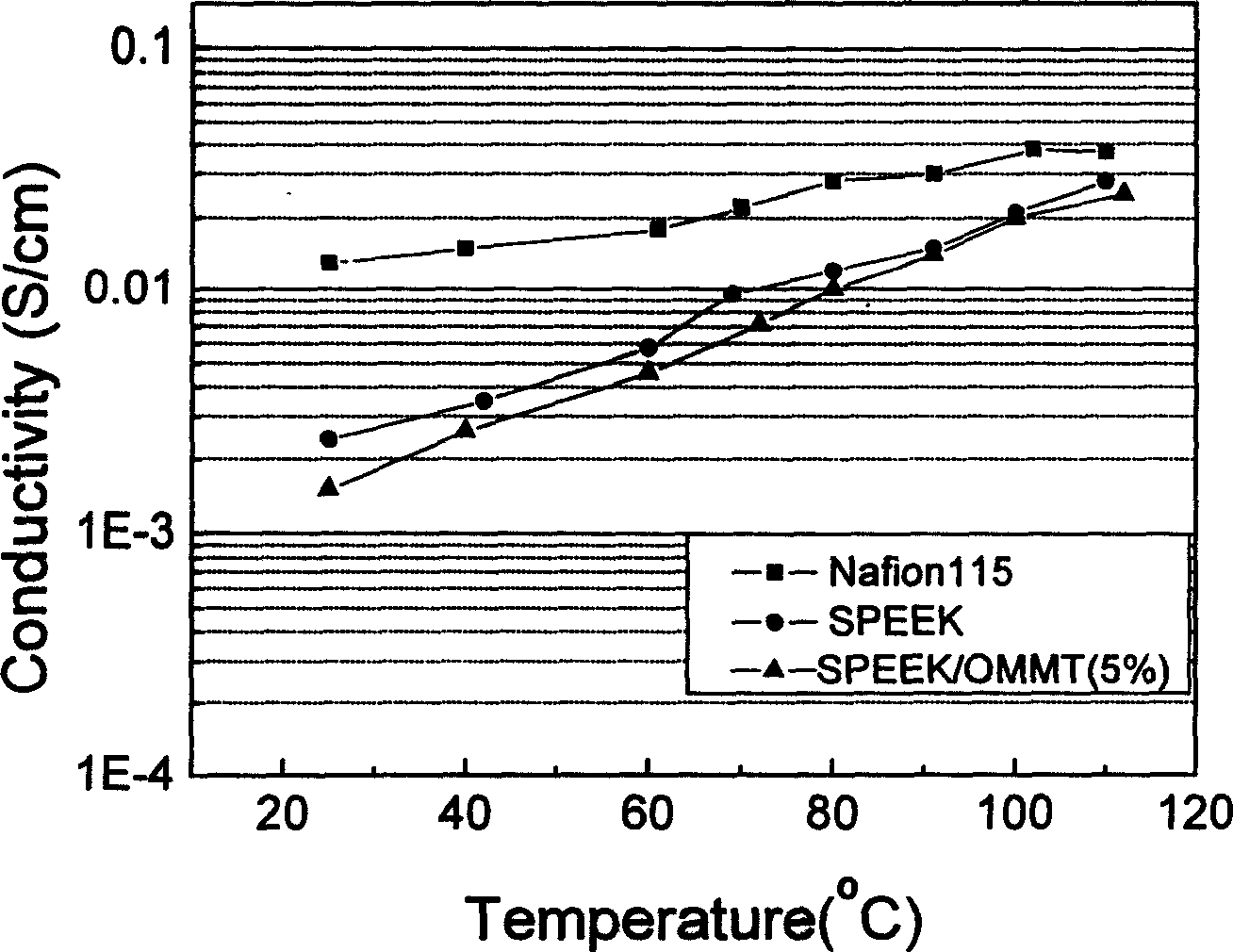

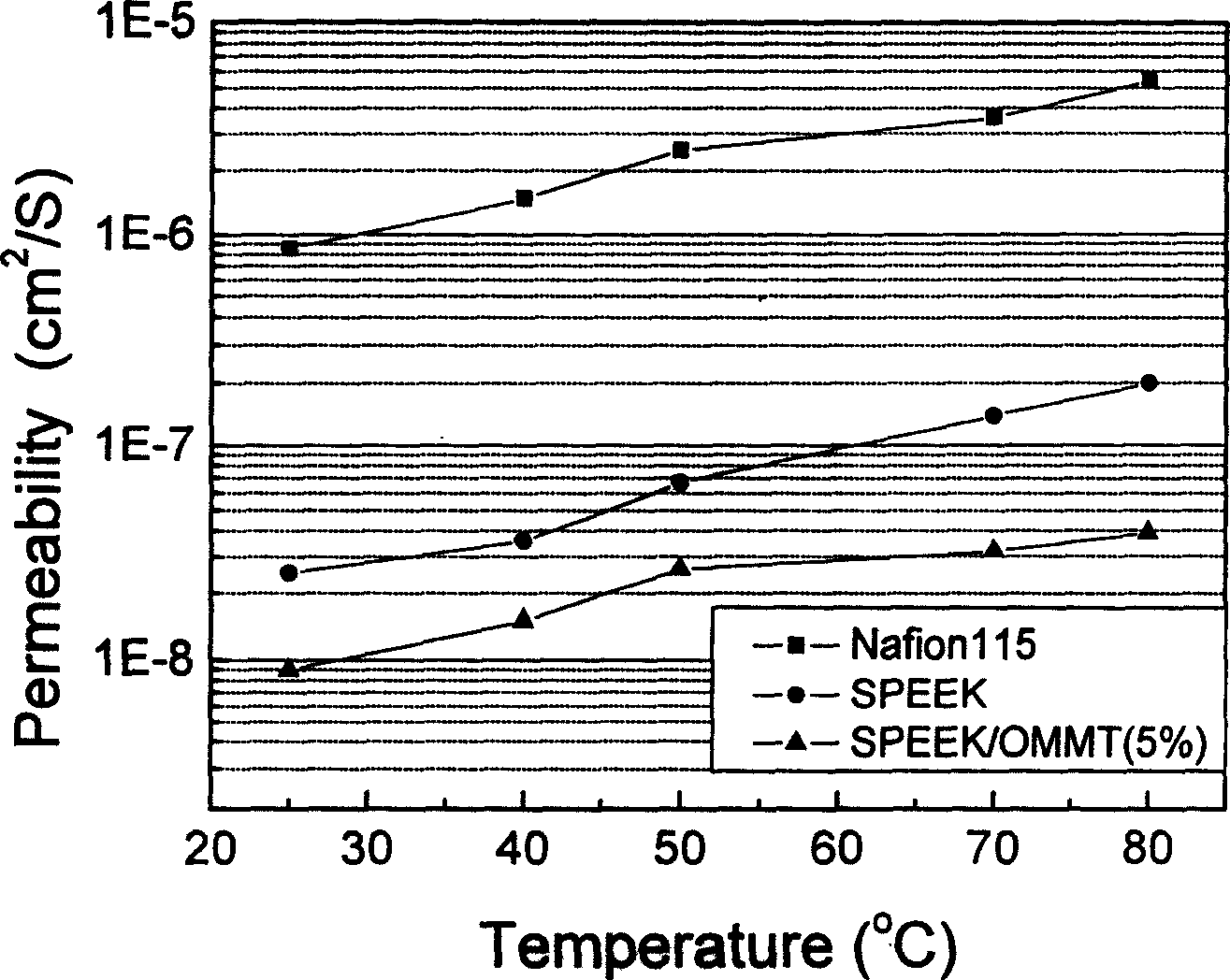

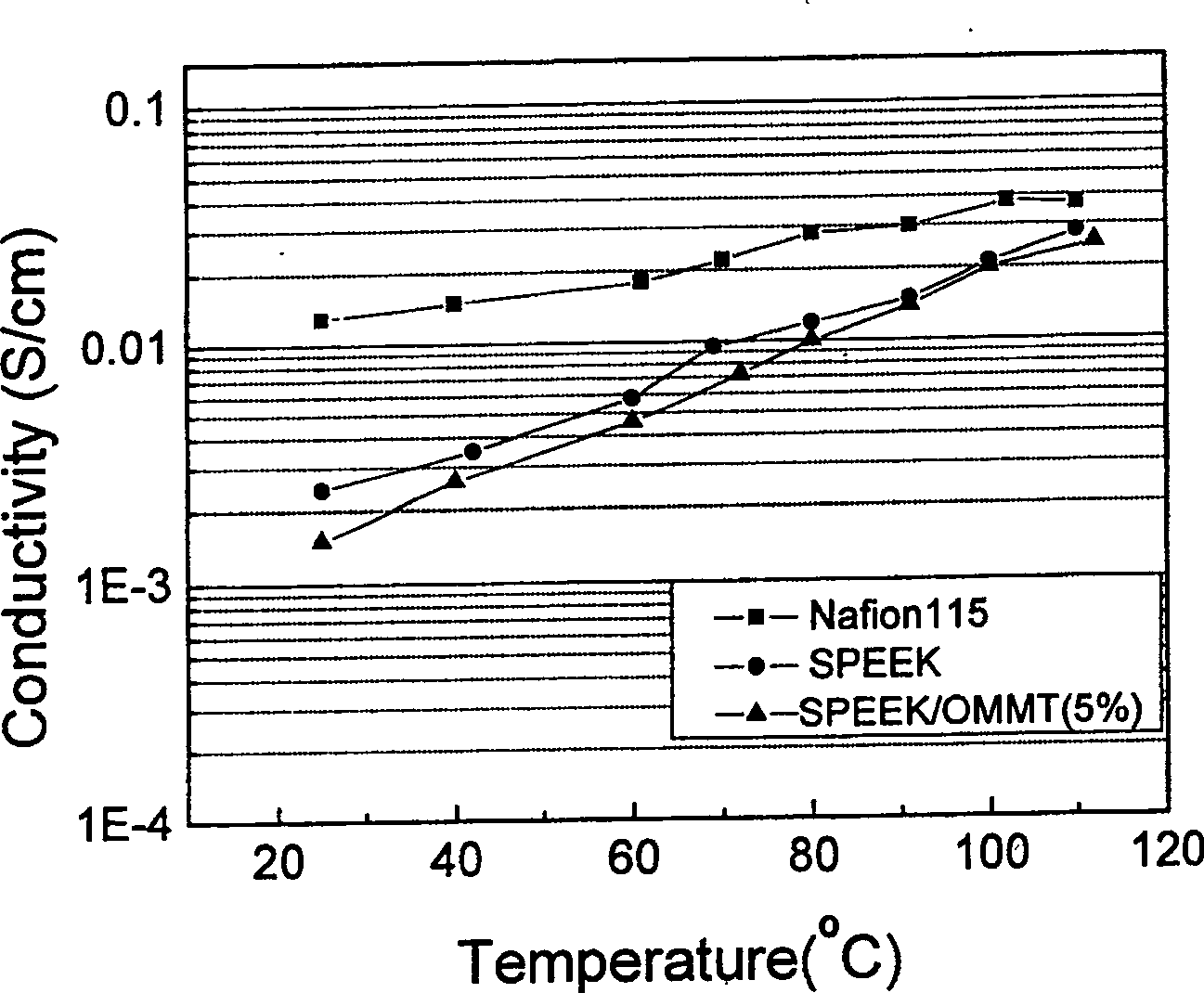

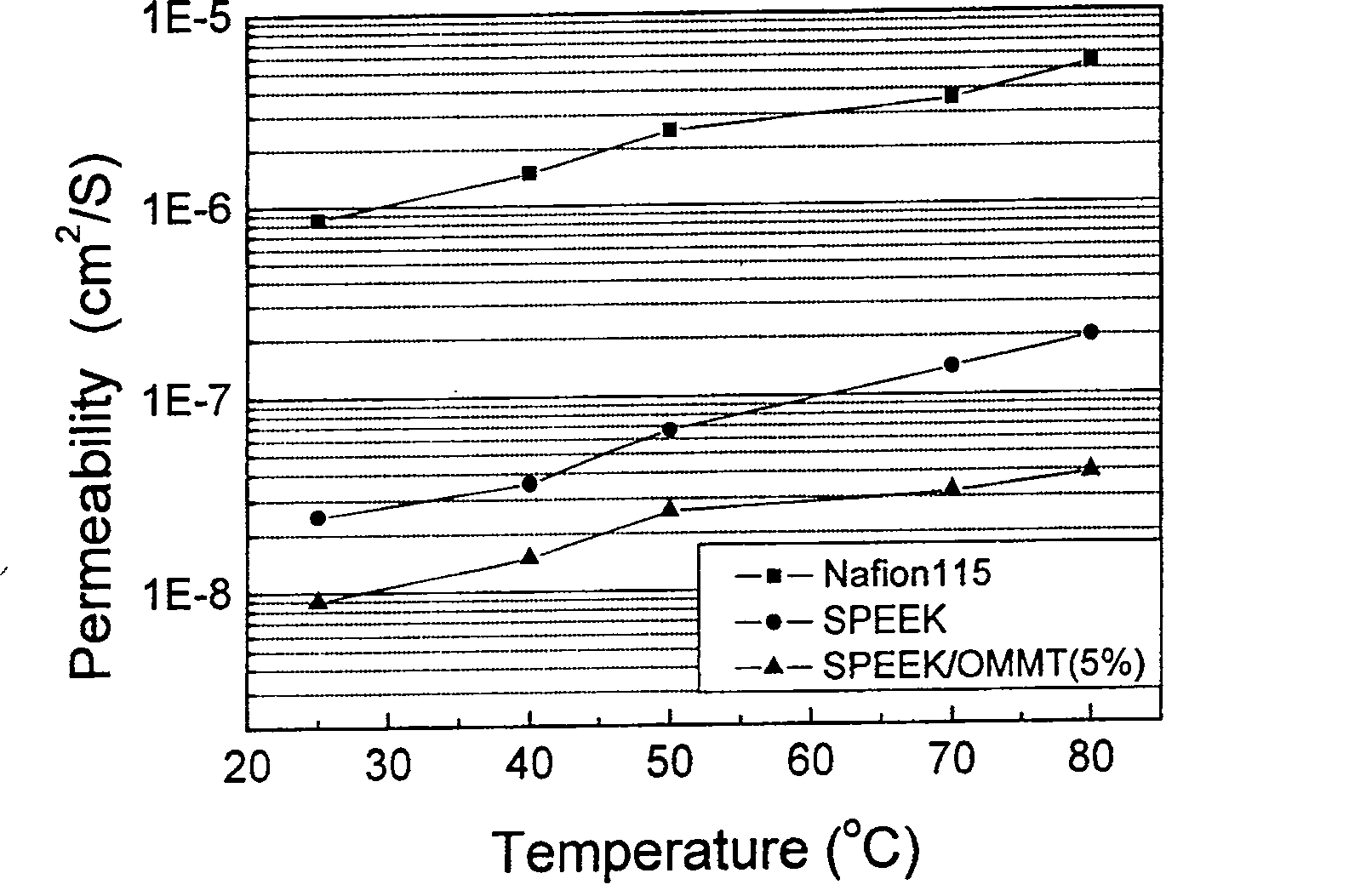

Organic-inorganic compoiste proton exchange film and preparing method

InactiveCN1677732AReduce penetrationIncrease profitCell electrodesFuel cellsPolymer scienceFuel cells

In the method, sulfonated polymer is dissolved in organic solvent. Added organic modified montorillonite clay is dispersed on basal body of polymer evenly. Membrane is formed through slobbering method. Through drying and stripping membrane in water produces membrane needed. Solving difficult problem of methanol infiltration of proton exchange membrane in use for direct fuel cell of methanol, the invention possesses features of simpler technique, and low cost of material etc.

Owner:SOUTH CHINA UNIV OF TECH

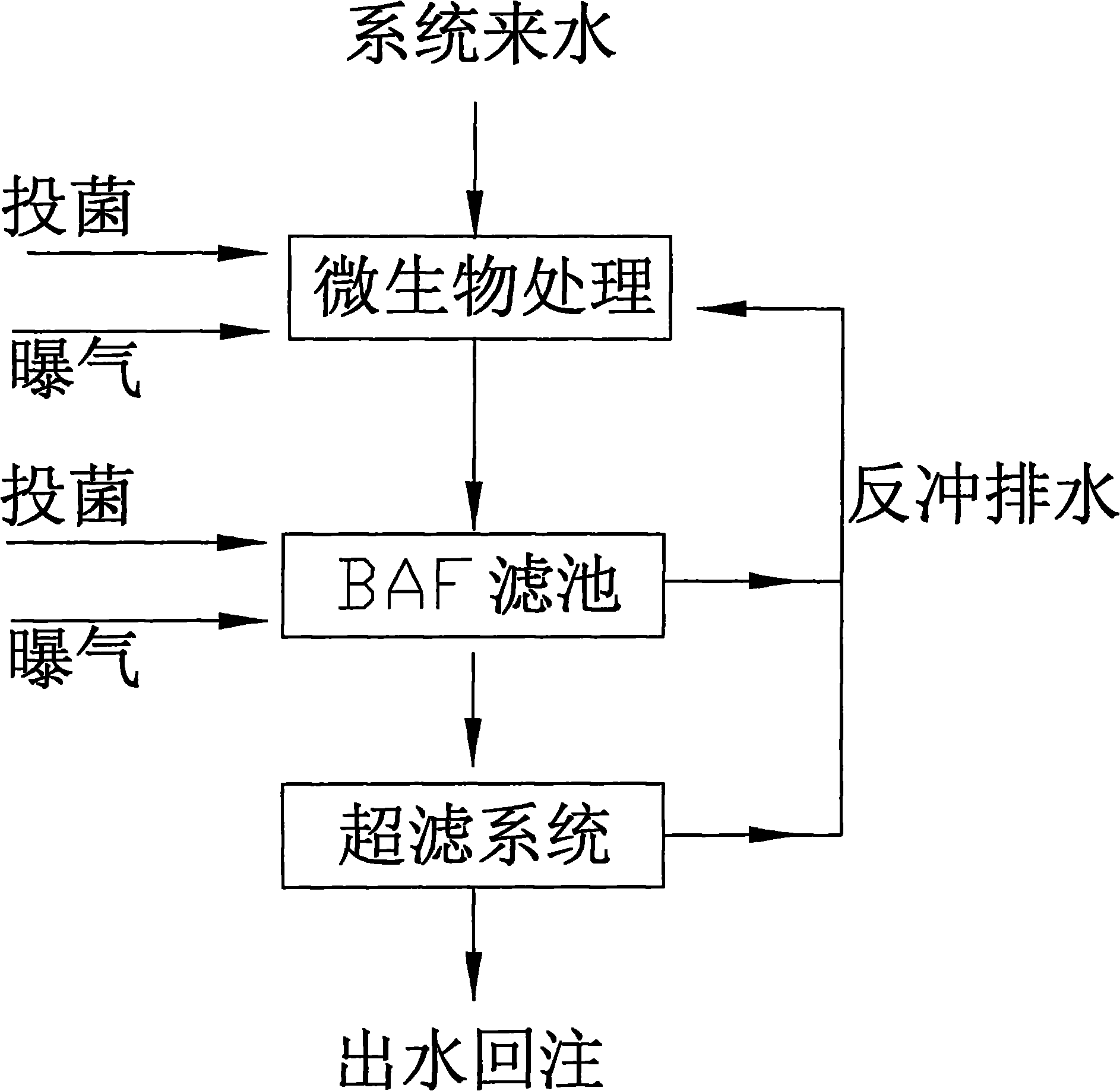

Hyposmosis/super-hyposmosis oil extraction sewage reinjection method in oil field

ActiveCN101973641AReduce productionIncrease profitSustainable biological treatmentBiological water/sewage treatmentZoogloea sp.Filtration

The invention relates to an improved hyposmosis / super-hyposmosis oil extraction sewage reinjection method in an oil field, which is characterized in that a combination strain of Zoogloea sp, Bacillus cereus and Pseudomonas alcaligenes mainly for removing oil and a combination strain of Brachybacteriumcollins Bacillus licheniformis Bacillus subtilis and Pseudomons sp for mainly degrading organic pollutants are respectively attached in an aerobic pool, and suspension filling with density of 65-85V / V% and / or separatly arranged suspension filling and biological aerated filter filling are filled and treated in sequence, wherein a separation membrane is a fiber membrane or vacuum membrane or gas stripping membrane or vibration membrane meeting the requirement on filtration, and the fine filtration is diatomite filtration. The synergistic effect of the process greatly improves the preprocessing effect to ensure that the follow-up membrane separation can adopt conventional economic separation treatment such as the hollow fiber membrane or vacuum membrane or gas stripping membrane or vibration membrane, or adopt the diatomite filtration. Compared with the prior art, the invention has the advantages of short treatment period and low investment and treatment cost.

Owner:JIANGSU BODA ENVIRONMENTAL PROTECTION

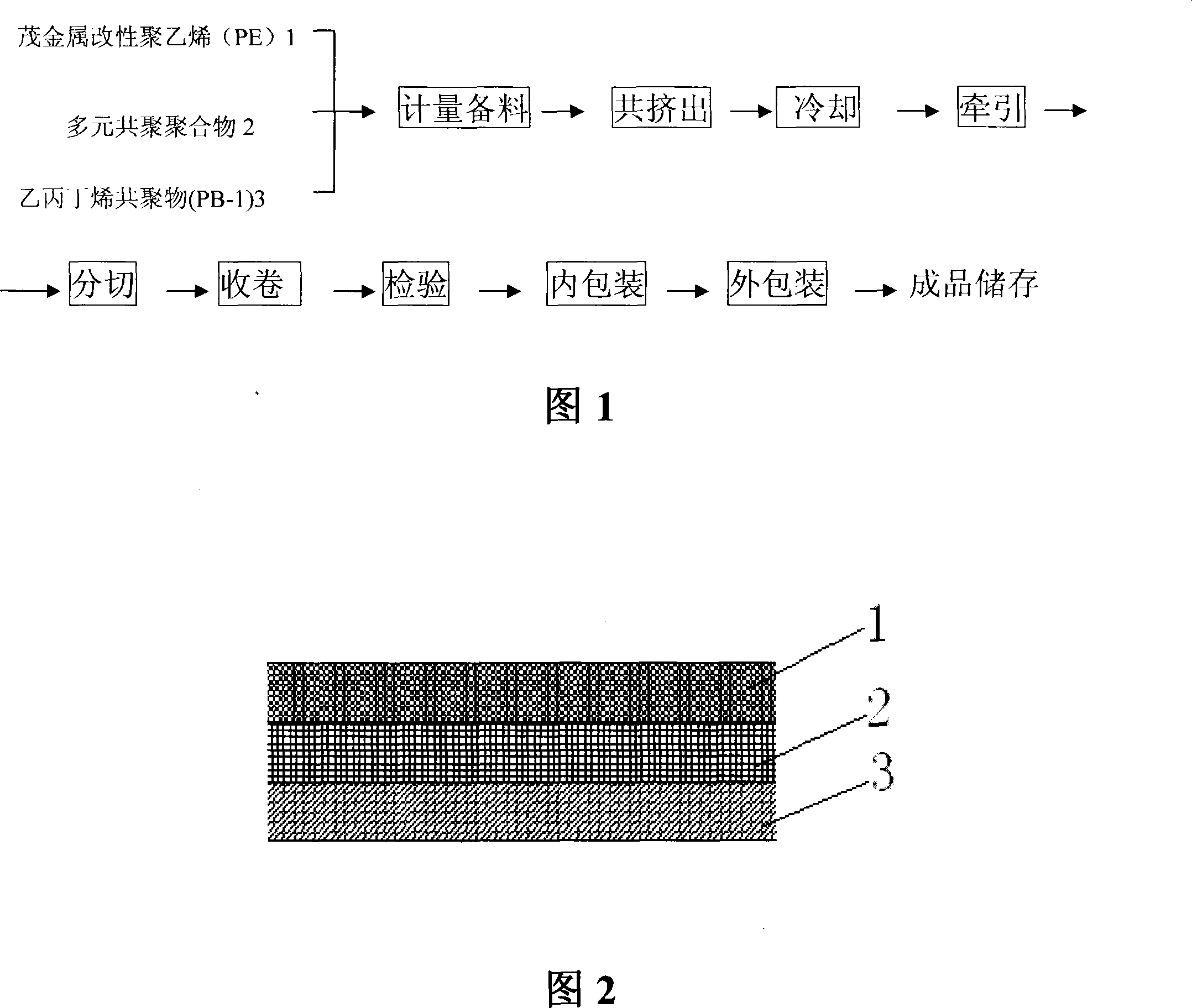

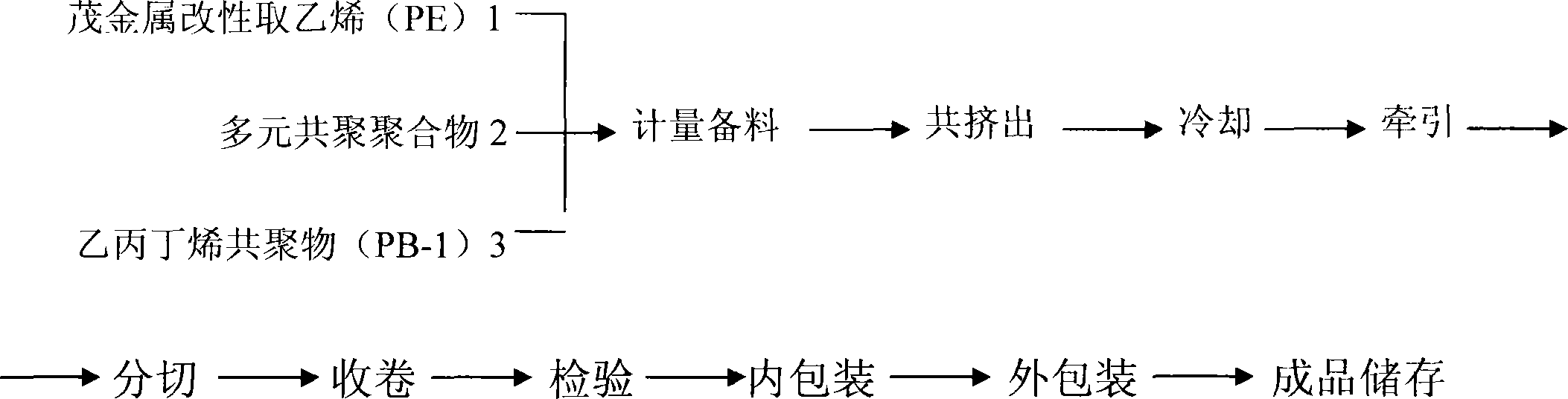

High-barrier thermophilic digestion resistant easy-stripping membrane

InactiveCN101181948AGood heat sealingGood sealingFlexible coversWrappersHigh resistanceEnvironmental resistance

The invention provides a high resistance and high temperature braising and cooking tearable membrane. The invention is characterized in that the invention consists of three layers of macromolecule material with good compatibility and close molecule structure, with the external layer is modified polyalkenes, the middle layer is multi-copolymerized polypropylene and the internal layer is terpolymer (ethene-ethylene-propylene butene). The modified polypropylene is metallocene modified polypropylene. The modified polypropylene occupies the proportion of 20% to 25%, the multi-copolymerized polypropylene occupies 50% to 60%, and the ethene-ethylene-propylene butene copolymer occupies 20% to 25%. The invention has extremely good biological inertia innocuity and is suitable for food packages; the invention does not generate the deformation, has wide applicable range, ensures the storages of convenient foods, children food, jelly, soft can, etc. not to be mortified or deteriorated, and reaches the requirement of asepsis (F0 is more than 8); the invention does not generate poisonous matters in the application and recovery process, has no pollution and belongs to environmental protective product.

Owner:郭瑞林

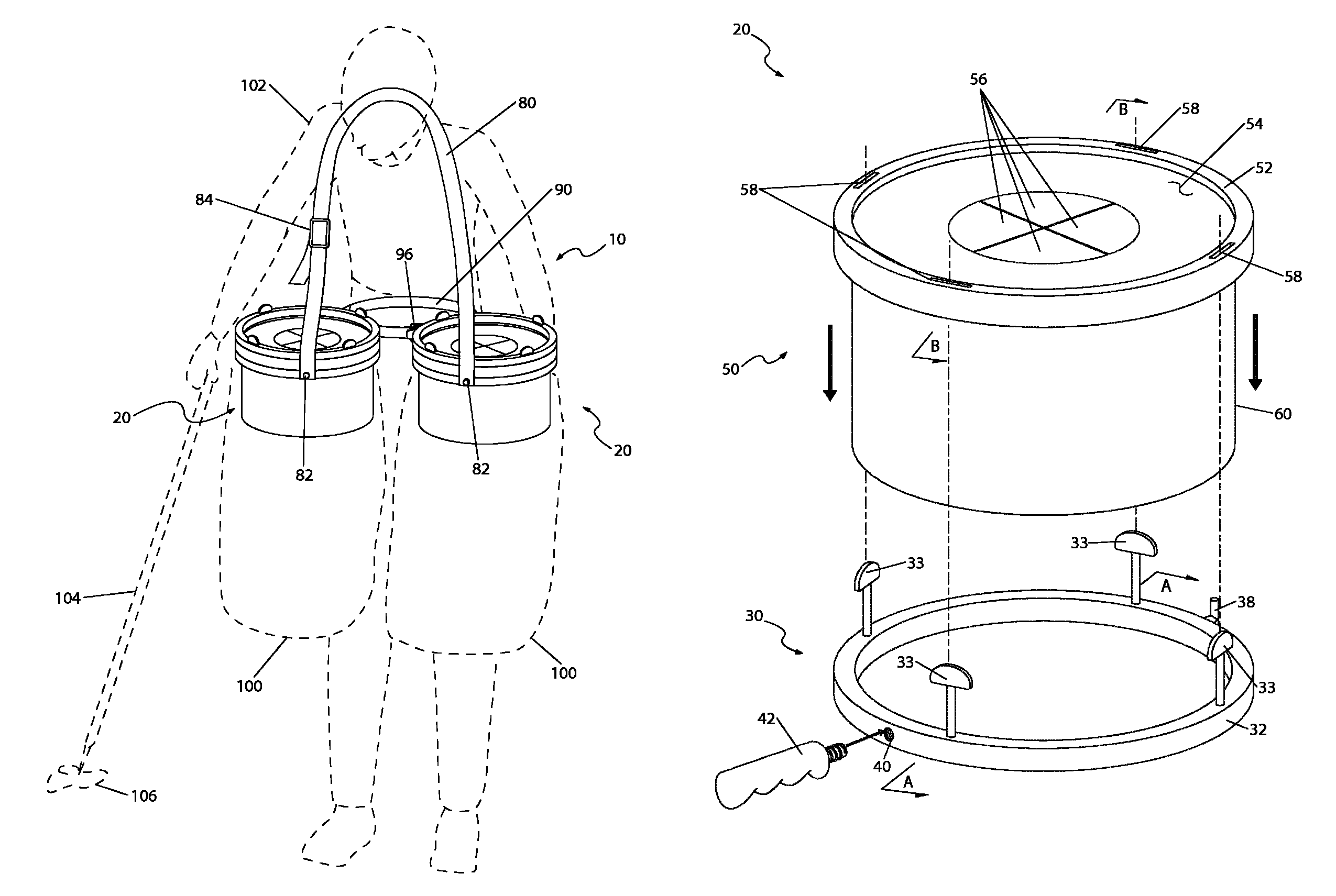

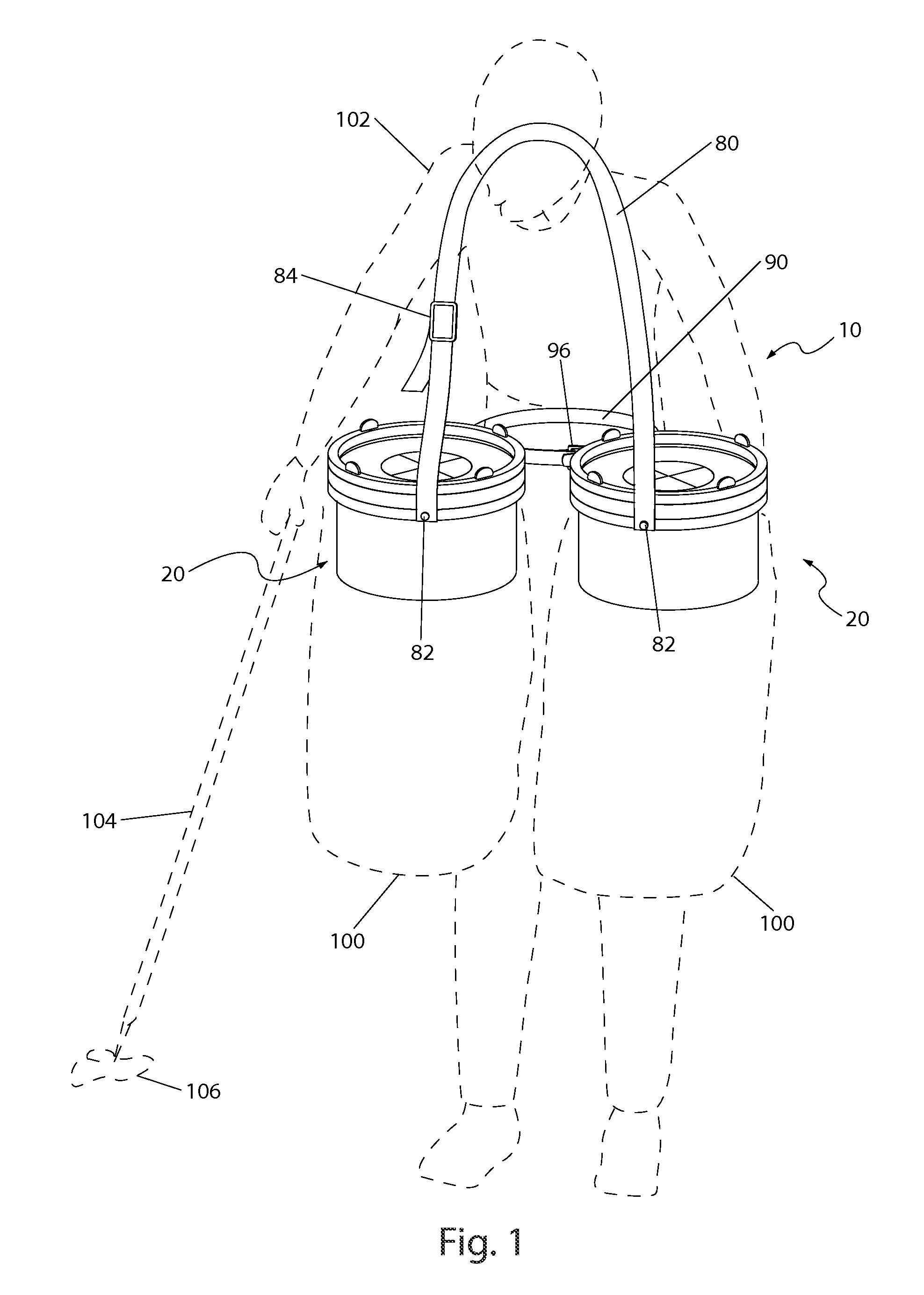

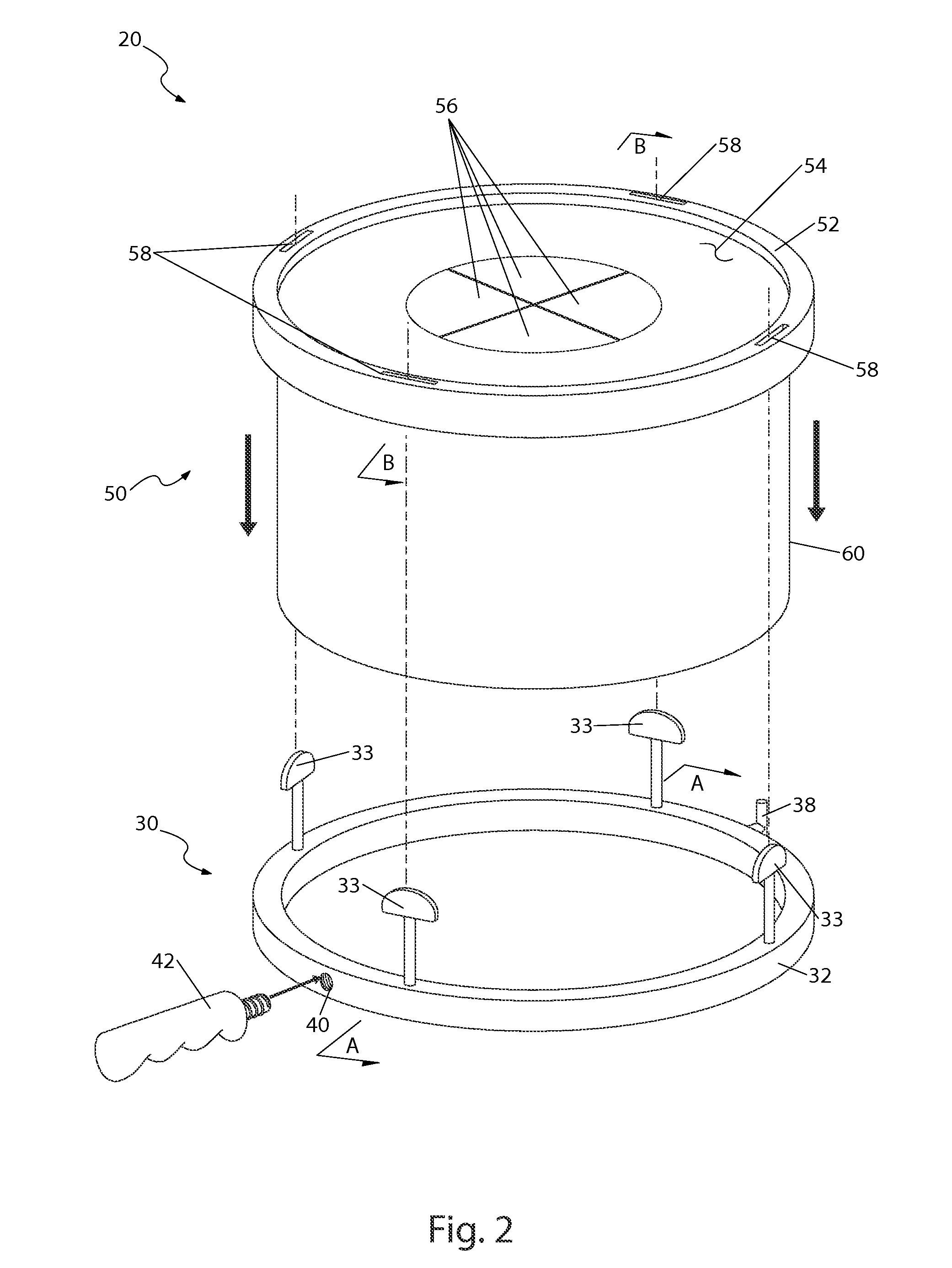

Personal trash bag holding apparatus

ActiveUS8770454B1Quick and easy and effectiveQuickly pick up trashTravelling sacksTravelling carriersLitterStripping membrane

An apparatus for holding trash bags and facilitating trash pick up includes a bag holding base ring and interchangeable insert ring and opening ring which selectably attach to the base ring. The trash bag is secured between the opposing pairs of rings, which are each attachable to a waist belt worn by the user or can be carried individually by an attachable handle. The insert ring also includes a stripping membrane along a top surface to remove the refuse from a trash picker and retain it inside the bag.

Owner:LUTZ SHANE

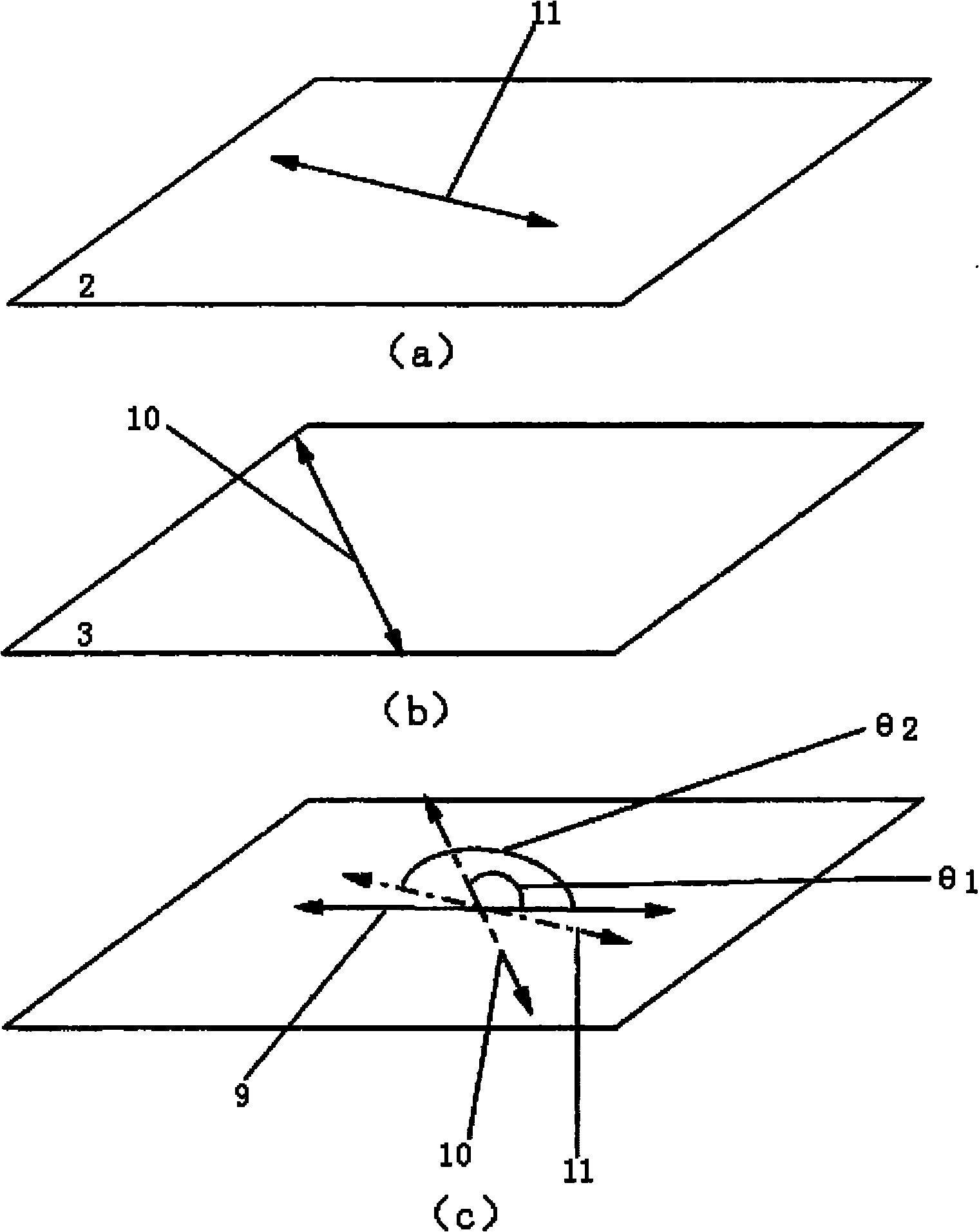

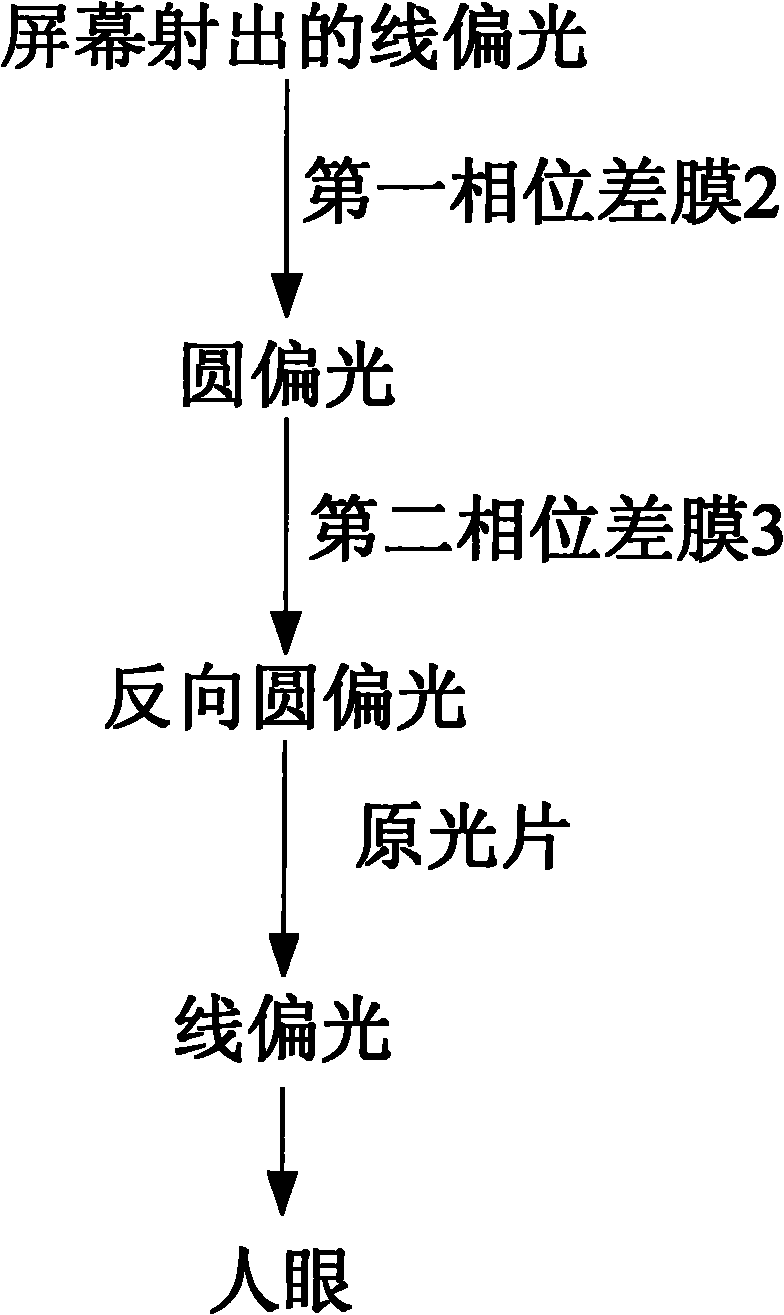

Method and polaroid for viewing movie by three-dimensional polaroid glasses at optional angle

ActiveCN102096203AAchieve transformationAchieve viewingLayered productsPolarising elementsPhase differenceStripping membrane

The invention discloses a method and a polaroid for viewing a movie by three-dimensional polaroid glasses at an optional angle. The polarization state change is as follows: linear polarized light emitted from a screen is converted into circular polarized light or elliptical polarized light by a first phase difference membrane, the circular polarized light or elliptical polarized light is converted into reversed circular polarized light or reversed elliptical polarized light by a second phase difference membrane, and the reversed circular polarized light or reversed elliptical polarized light is converted into the linear polarized light to enter the human eyes by an original light plate. The polaroid comprises a first outer protective film, a first phase difference membrane, a second phase difference membrane, the original light plate and a stripping membrane in turn from the top to the bottom, wherein all above structures are in adhesive connection by adhesives. In the invention, the polaroid is formed by superposing two layers of phase difference membranes with a phase difference between different surfaces on the basis of the original light plate, so the conversion between the linear polarized light and the elliptical polarized light or circular polarized light is realized smoothly. Thus, three-dimensional movie can be watched at an optional angle.

Owner:SHENZHEN SAPO PHOTOELECTRIC

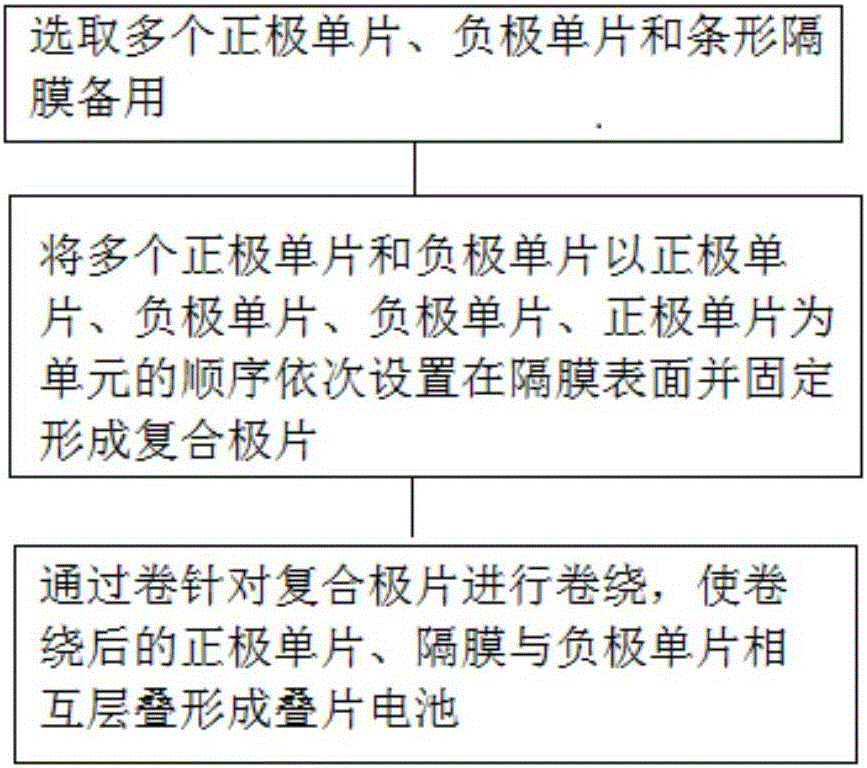

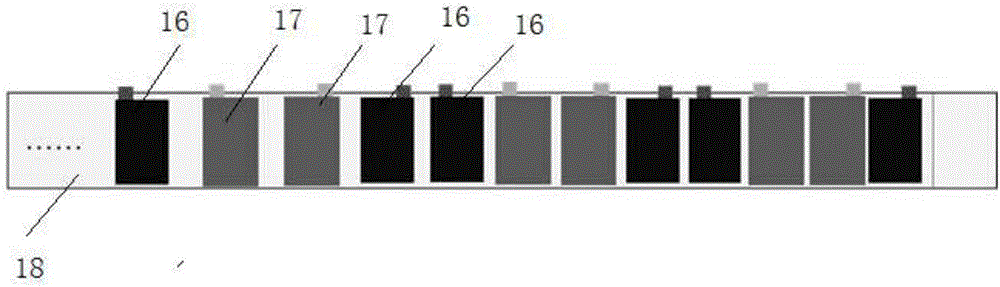

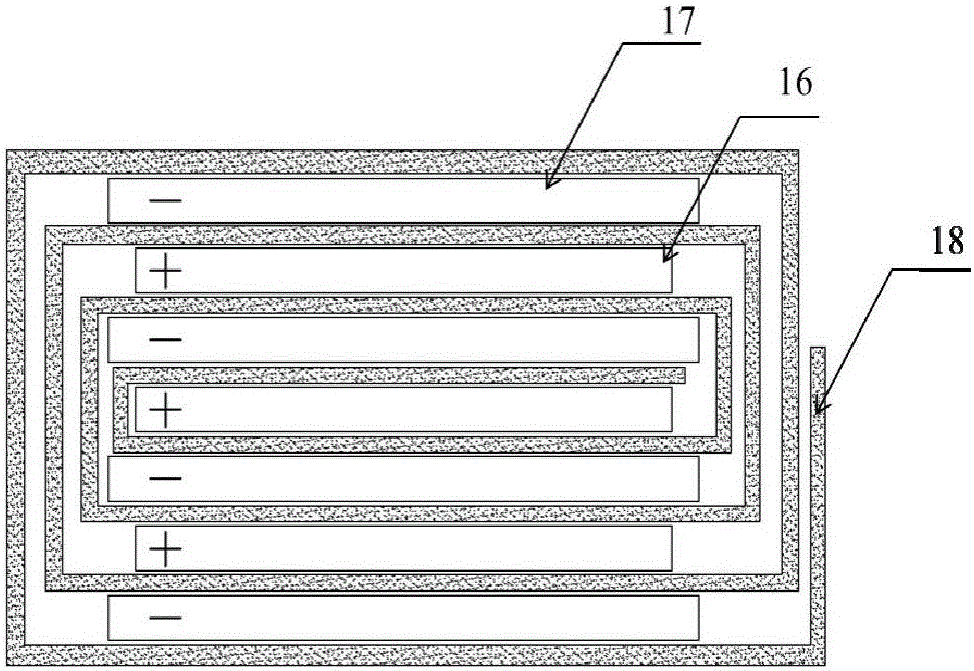

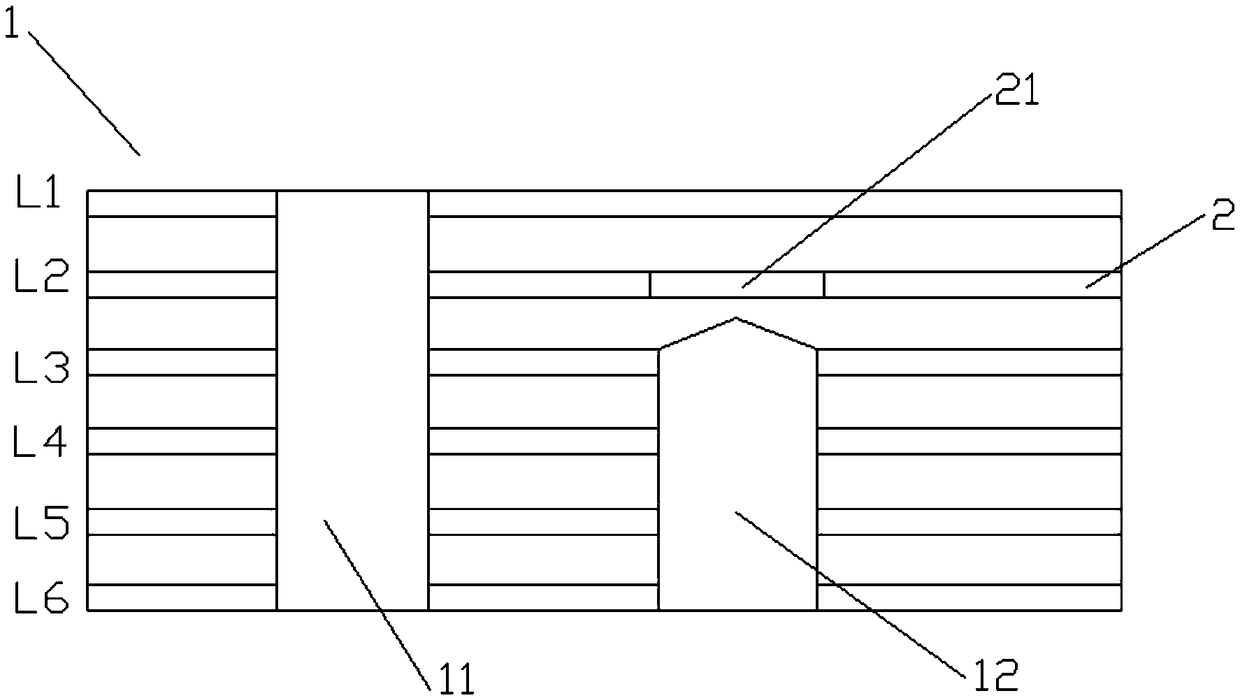

Fast preparation method of wound lithium-ion laminated battery

InactiveCN105932339AImprove production efficiencyReduce productionFinal product manufactureSecondary cellsLithiumWhole body

The invention relates to a fast preparation method of a wound lithium-ion laminated battery. The method comprises the following steps: (1) selecting a plurality of cut single positive pole pieces, single negative pole pieces and a strip membrane for later use; (2) sequentially arranging the single positive pole pieces and the single negative pole pieces on the surface of the membrane in an order of the single positive pole piece, the single negative pole piece, the single negative pole piece and the single positive pole piece as units and forming a composite pole piece in a fixed manner; and (3) winding the composite pole piece through a winding needle, and mutually stacking the wound single positive pole pieces, membrane and single negative pole pieces to form the laminated battery. By the fast preparation method of the wound lithium-ion laminated battery, the wound lithium-ion laminated battery is formed by stacking the positive pole pieces and the negative pole pieces in a winding manner; the minimum structure unit of the wound laminated battery is the single positive pole pieces and the single negative pole pieces; the fabricating, cutting, fixing and transferring steps of a multi-layer structure unit are omitted; the gummed membrane adopted by the method is a continuous un-cut whole body; and the manufacturing efficiency of the laminated battery is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

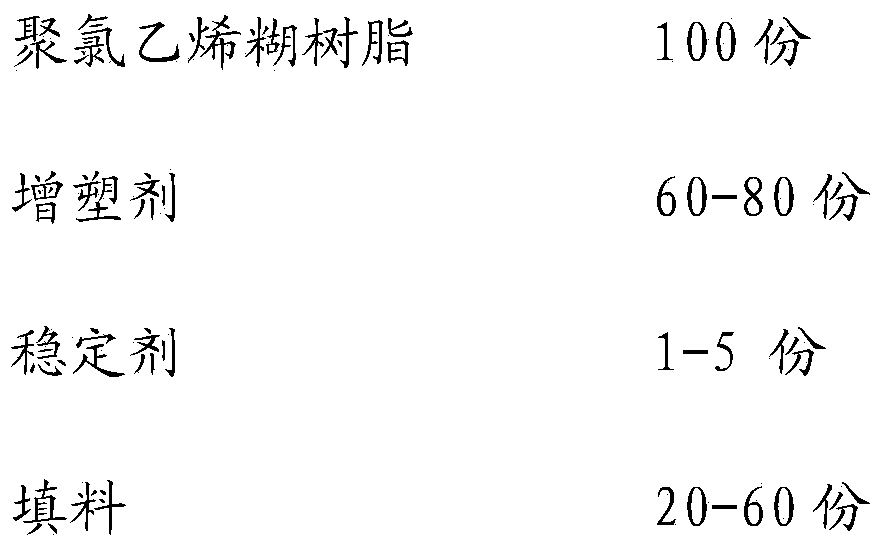

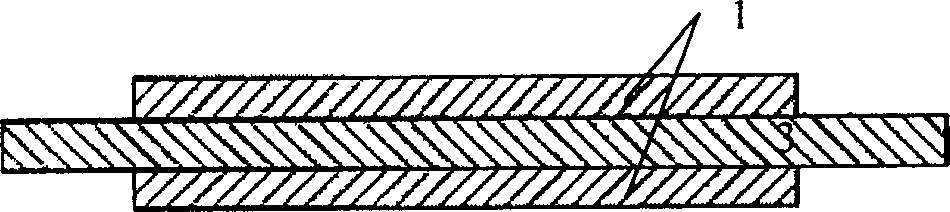

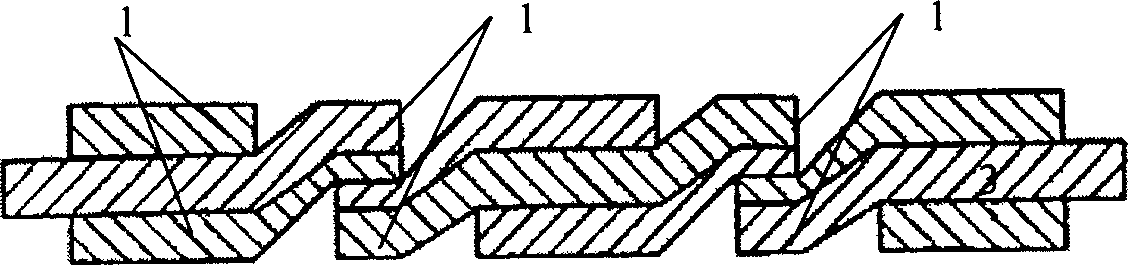

Novel coating membrane material used for tarpaulin clamping strip and preparation method of novel coating membrane material

InactiveCN105369646AAchieve the effect of fixing yarnReduce loose yarnCoatingsTextiles and paperYarnStripping membrane

The invention discloses a novel coating membrane material used for a tarpaulin clamping strip and a preparation method of the novel coating membrane material. The novel coating membrane material used for the tarpaulin clamping strip comprises a wicking-resistant base cloth layer, a first PVC coating, a second PVC coating, a third PVC coating and a polyurethane printing layer, wherein the front side of the wicking-resistant base cloth layer is coated with the first PVC coating, the back side of the wicking-resistant base cloth layer is coated with the second PVC coating, the surface of the first PVC coating is coated with the third PVC coating, and the surface of the second PVC coating is coated with the polyurethane printing layer; the wicking-resistant base cloth layer is made of wicking-resistant base cloth. According to the novel coating membrane material, the wicking-resistant base cloth is coated with the first PVC coating and the second PVC coating, so that the effect of fixing yarn to the clamping strip membrane material is achieved, the phenomena of yarn loosening and filament falling occurring in the processing process of the clamping strip membrane material are reduced, the operation speed is raised, and operation convenience is improved, The surface of one of the PVC coatings is coated with the polyurethane printing layer, so that waterproofness, the anti-mold property and wear resistance of the clamping strip membrane material are improved, and the service life of a tent is directly prolonged.

Owner:FOSHAN GAOMING YILONG PLASTICS & RUBBER IND

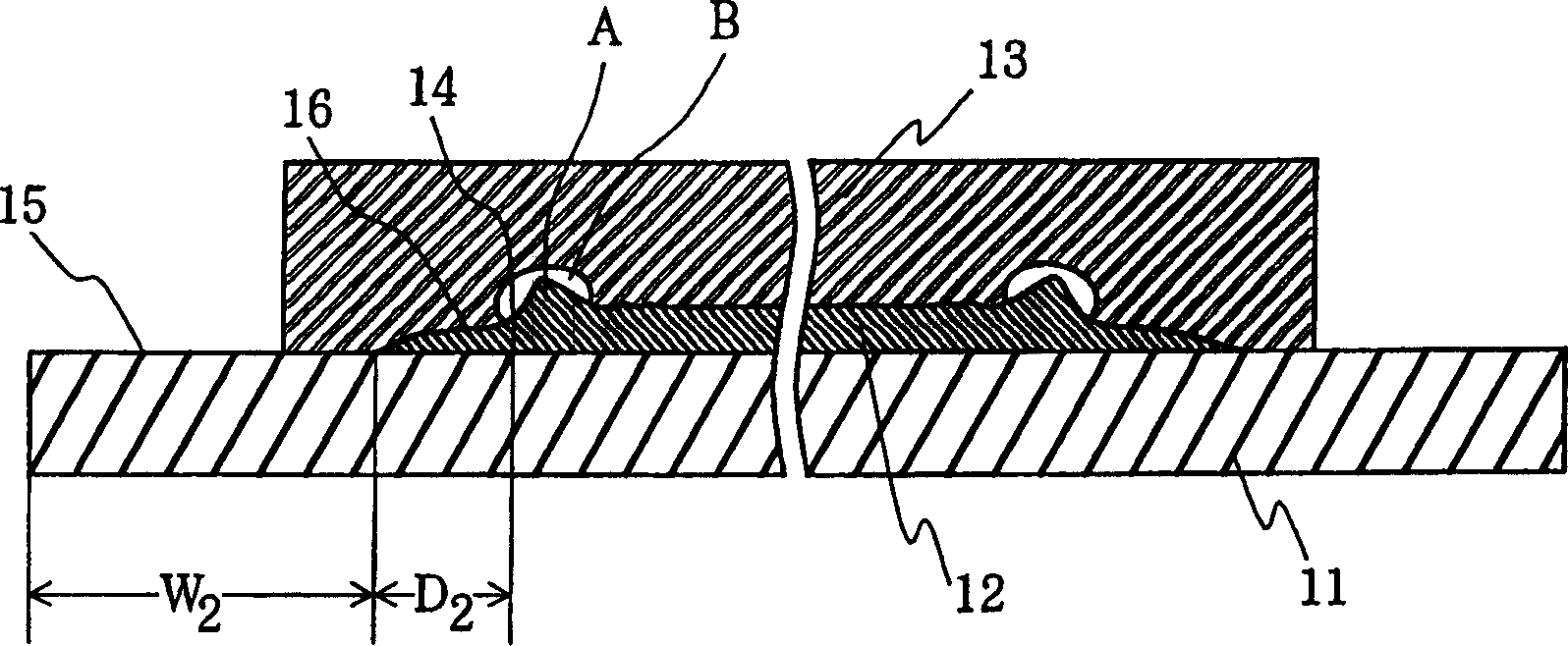

Solid polymer fuel cell unit and its cell stack

InactiveCN1477728AIncrease the output voltageReduce internal resistance power consumptionFuel cells groupingSolid electrolyte fuel cellsFuel cellsInternal resistance

The present invention relates to a solid polymer fuel cell unit and its cell pile, and relates to a structure design of solid polymer fuel cell using membrane electrode three-into-one component as core. The cell unit is formed from separated strip membrane electrode component and flow field distributing plates arranged at two sides of said component, and the strip membrane electrode component is formed from one whole piece of solid polymer membrane and several separated strip electrodes which are distributed at two sides of the membrane and alternatively arranged according to positive and negative polarities, and its cell pile is made up by longitudinally-arranging several blocks of cell units.

Owner:TSINGHUA UNIV

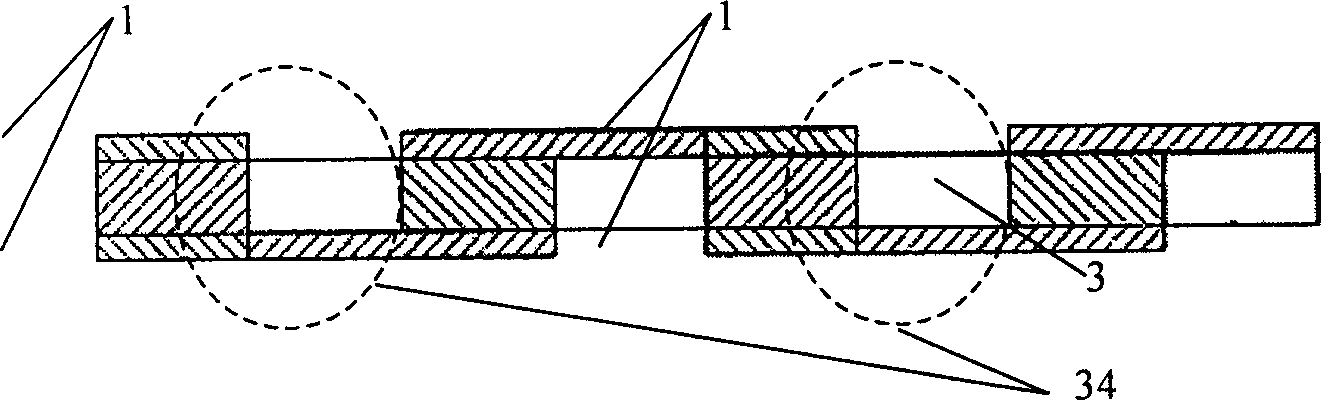

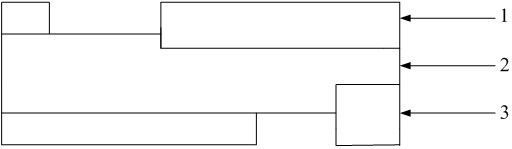

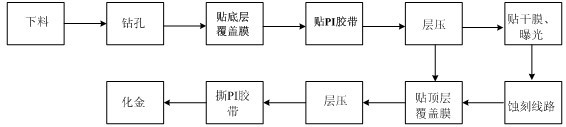

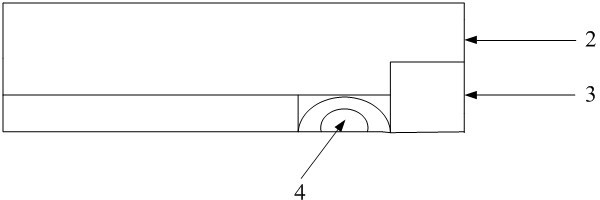

Manufacturing process of single panel gold finger

ActiveCN102427680AAvoid deformationAvoid wrinklesPrinted element electric connection formationStripping membraneAdhesive

The invention provides a manufacturing process of a single panel gold finger. The gold finger comprises: a top cover membrane layer arranged on an upper layer, a pure copper foil layer arranged in the middle and a bottom cover membrane layer arranged on the bottom. An opening is arranged on the bottom cover membrane layer. The manufacturing process comprises the following steps: a joint step: sticking a PI adhesive tape which is larger than the opening on the opening of the cover membrane layer; a laminated step: laminating the gold finger and the PI adhesive tape together, sticking the top cover membrane layer on the laminated product and then carrying out lamination; an evulsion step: evulsing the laminated PI adhesive tape; a processing step: processing on the top cover membrane layer and the opening of the bottom cover membrane layer. By using the manufacturing process of the invention, deformation and corrugation of the hollow finger during a process of after etching line stripping membrane to laminated top cover membrane in this kind of products can be avoided. A production yield rate of the products can be substantially increased.

Owner:博罗县精汇电子科技有限公司

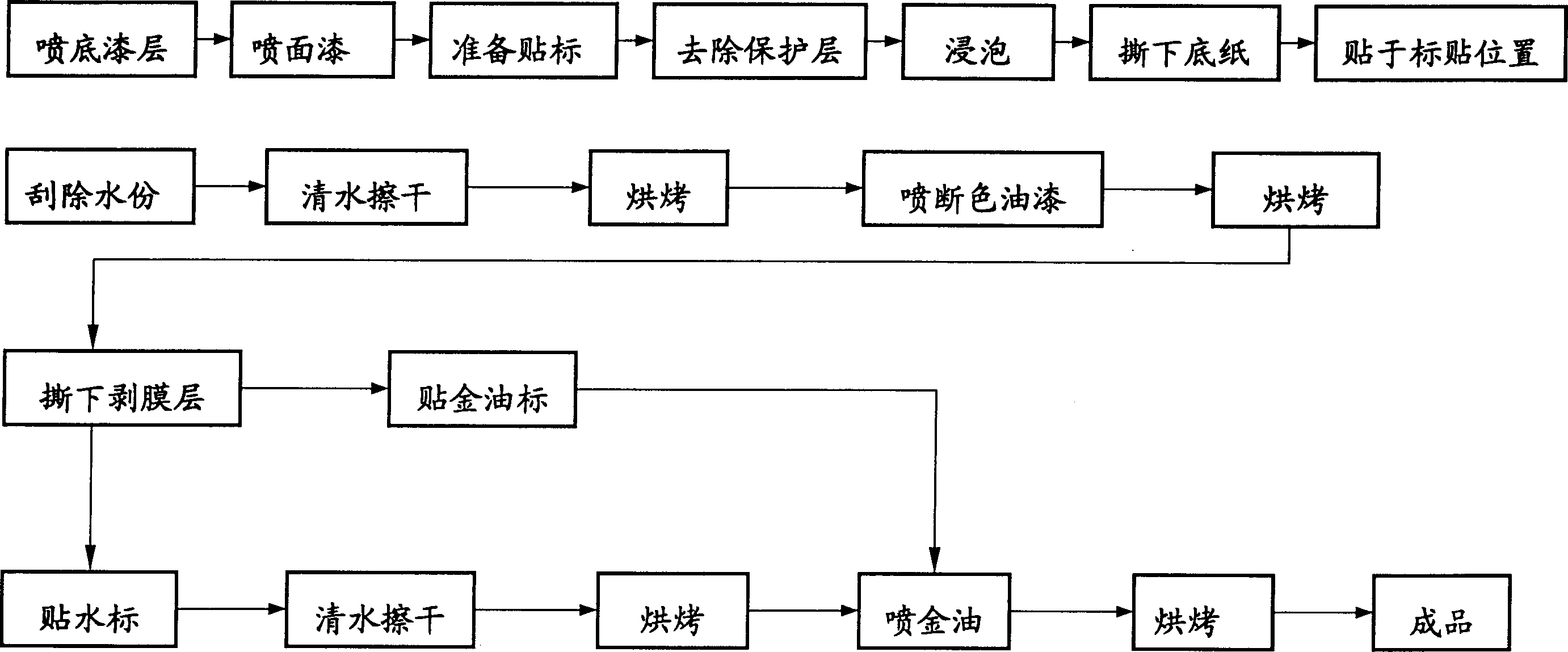

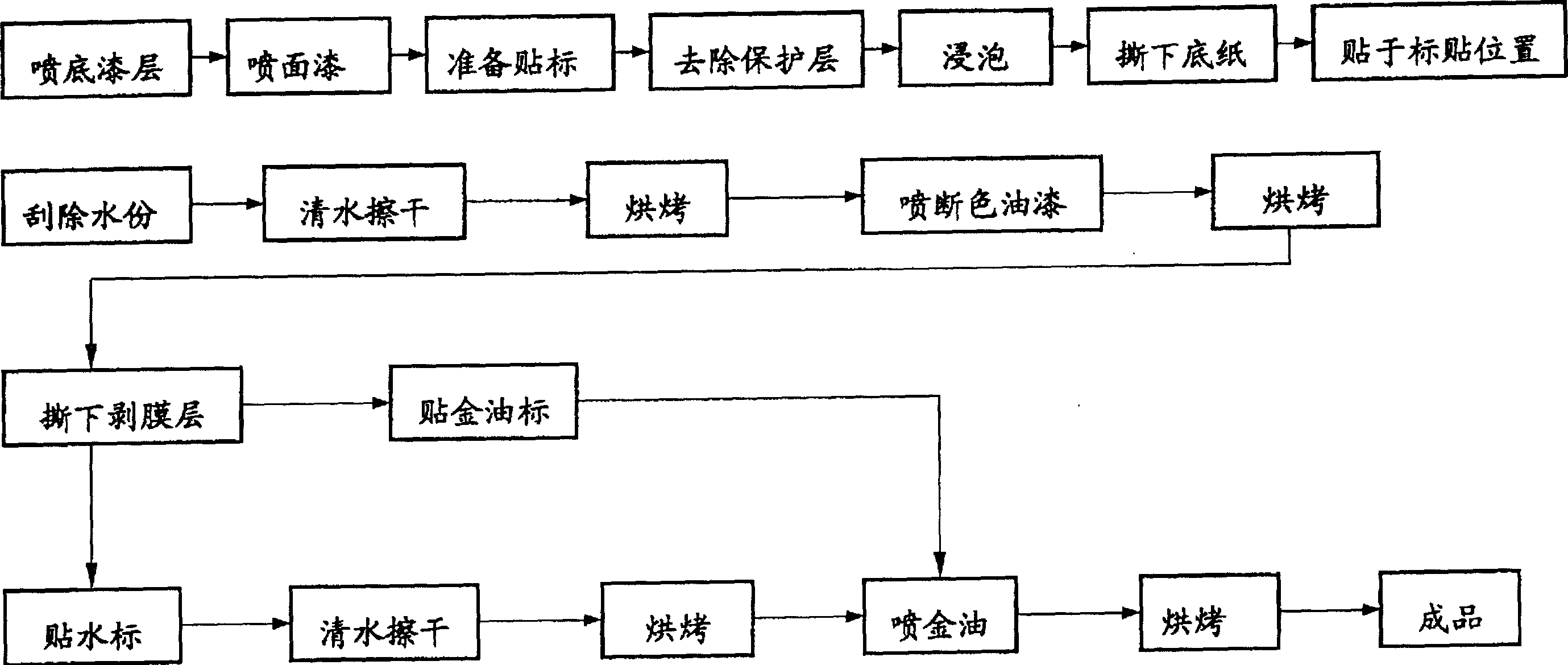

Coating method for bicycle

InactiveCN1411917AStrong adhesionImprove adhesionPretreated surfacesCoatingsStripping membraneEngineering

Owner:刘国彰

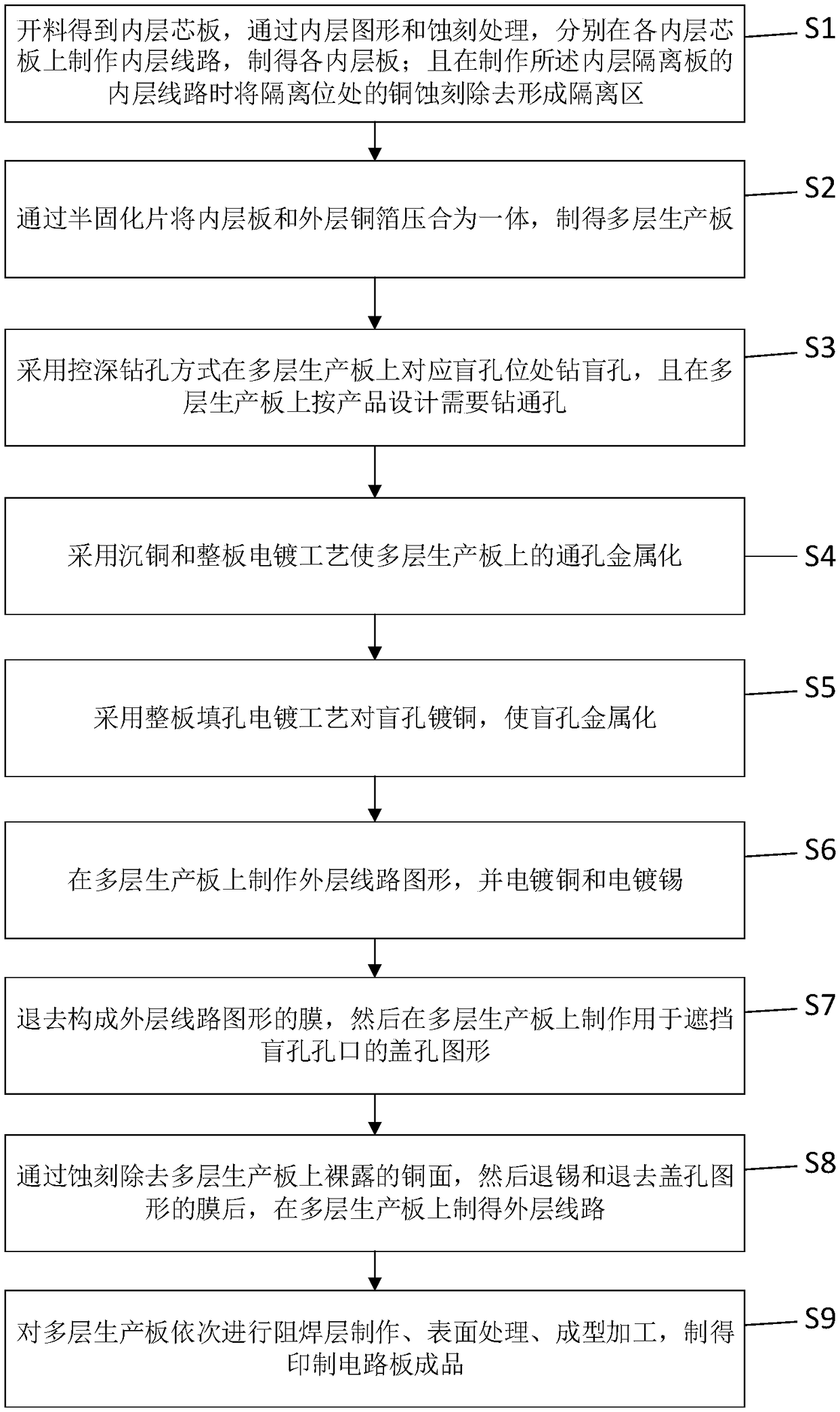

Printed circuit board with blind hole instead of back drill hole and manufacturing method thereof

InactiveCN108925042AEffective isolationAvoid short circuitPrinted element electric connection formationCopper platingStripping membrane

The invention provides a manufacturing method of a printed circuit board with a blind hole instead of a back drill hole, comprising the following steps: S1, cutting and preparing each inner layer plate; etching and removing copper at an isolation position to form an isolation region; S2, preparing a multi-layer production board; S3, drilling blind holes in the corresponding blind hole position onthe multi-layer production board, and drilling through holes in the multi-layer production board; S4, adopting a copper plating and whole-plate electroplating process to make the through holes in themulti-layer production board metallized; S5, using a whole-plate hole filling electroplating process to plate copper on the blind holes so as to metallize the blind holes; S6, manufacturing an outer layer circuit pattern on the multi-layer production board, and electroplating copper and electroplating tin; S7, stripping membrane and manufacturing a cover hole pattern on the multi-layer productionboard for blocking the hole port of the blind hole; S8, removing a copper plane exposed on the multi-layer production board by etching; then, removing the tin and manufacturing an outer-layer circuiton the multi-layer production board; S9, manufacturing a finished product of the printed circuit board. The invention further provides a printed circuit board with the blind hole instead of the back drill hole.

Owner:珠海崇达电路技术有限公司 +1

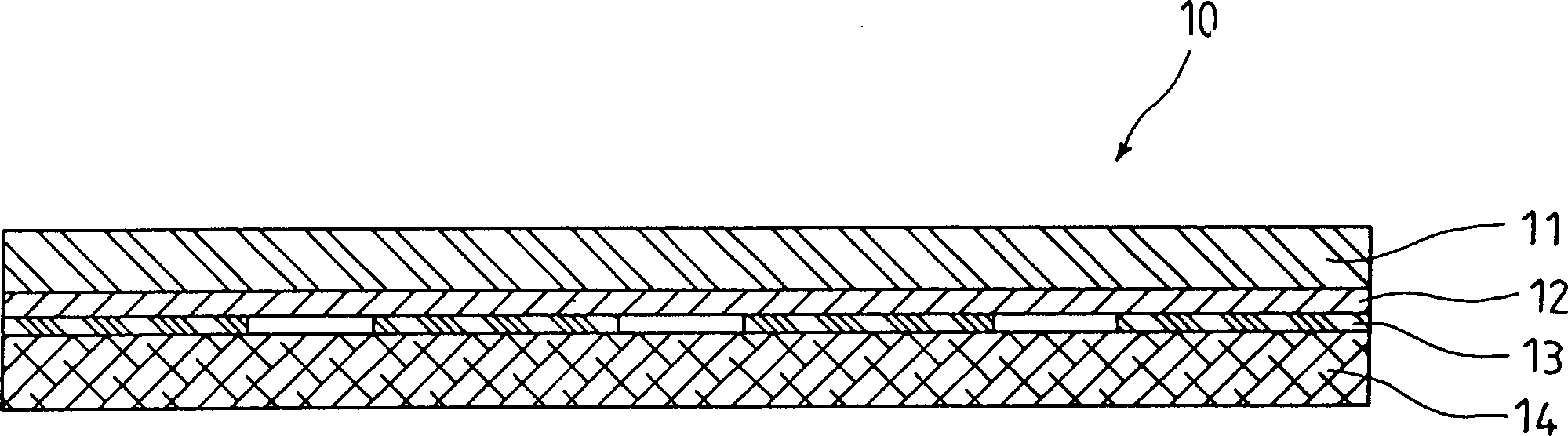

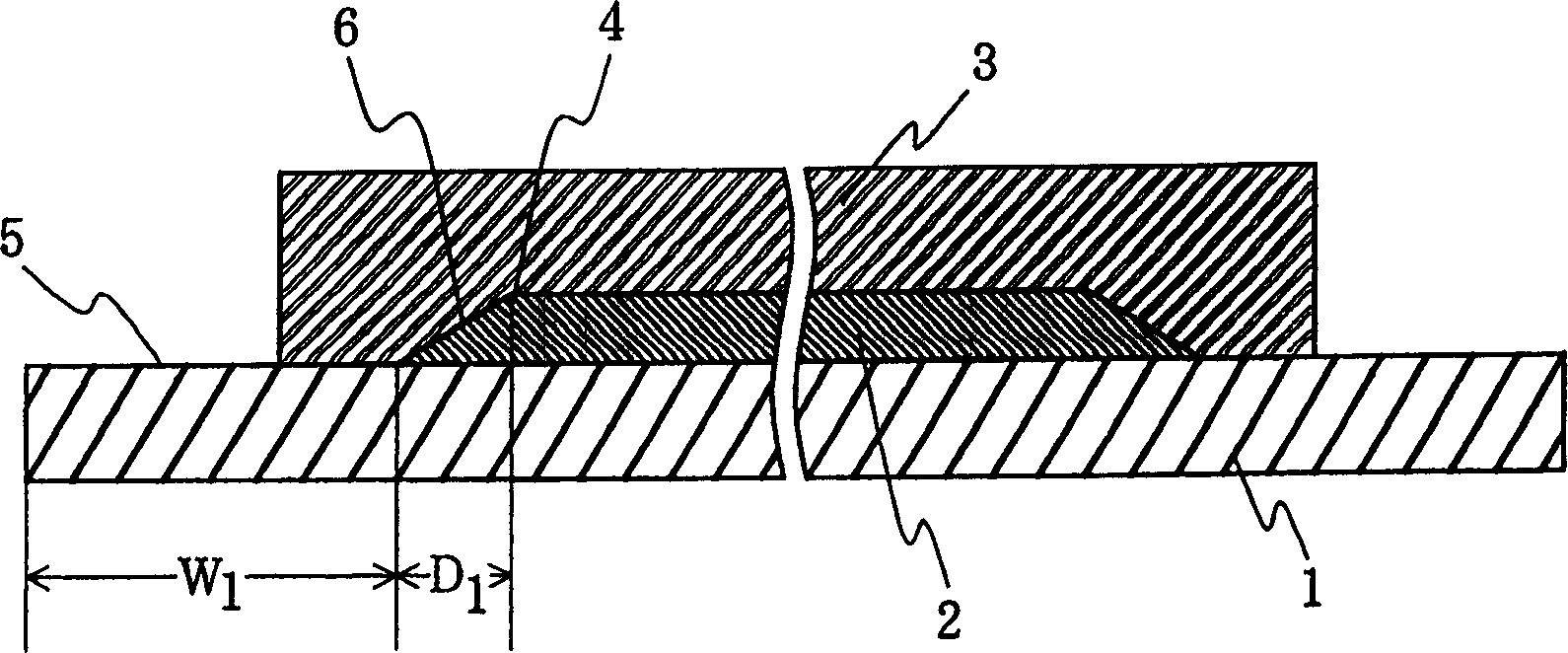

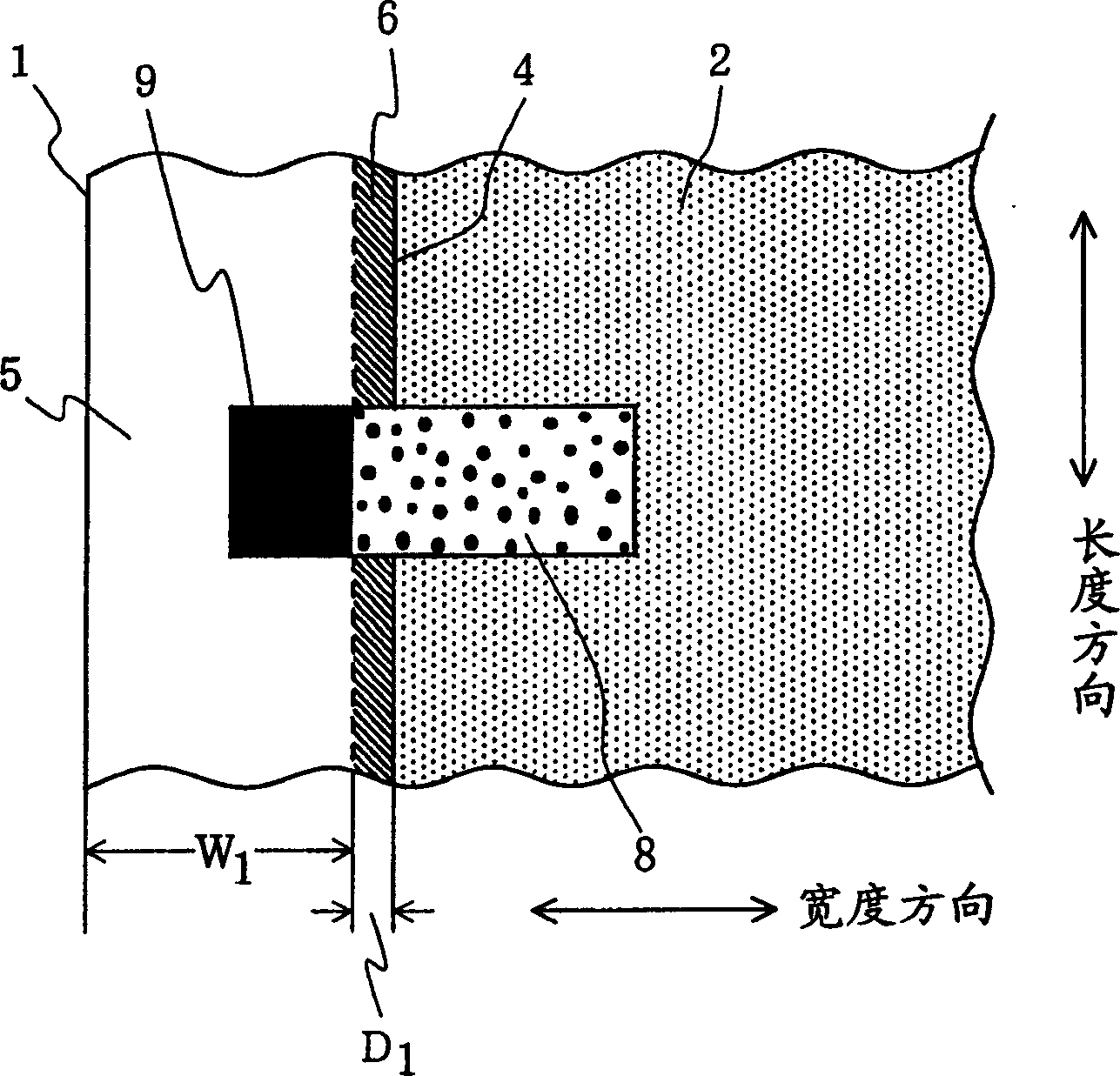

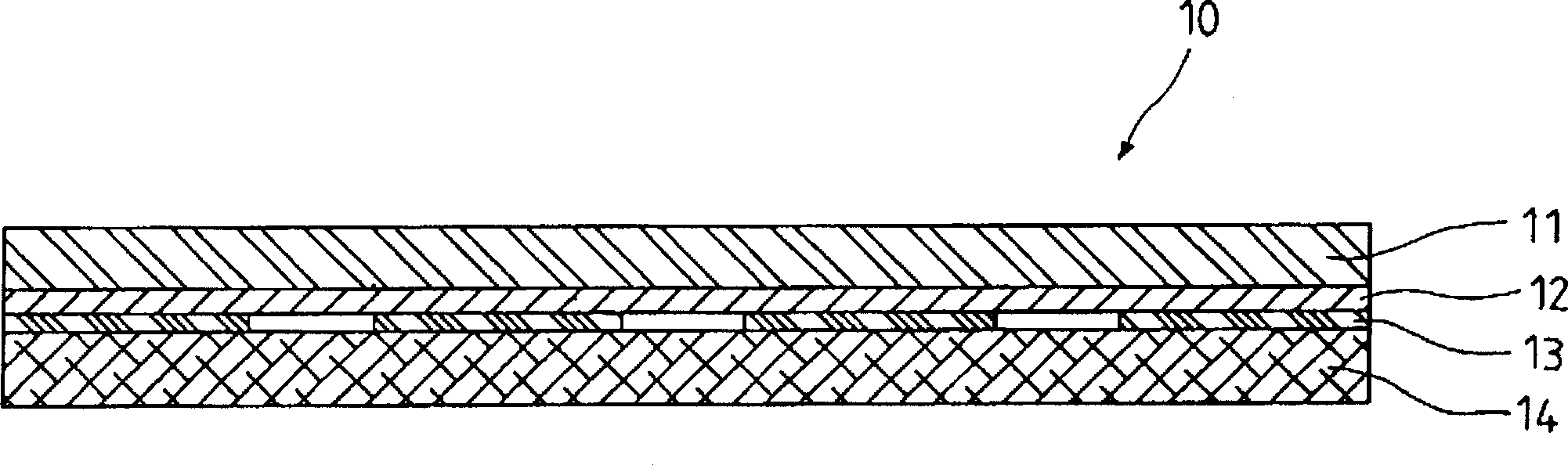

Stripping film and its mfg. method

InactiveCN1533885AGood size shapeNo bouncingStacked capacitorsCeramic layered productsStripping membraneCeramic substrate

A stripping membrane for preparing the ceramic substrate of printed circuit by coating ceramic paint on it and then stripping the ceramic paint layer from it, and its preparing process are disclosed. The obtained ceramic substrate has high size and shape precision. Said stripping membrane is prepared through coating it on at least one surface of basic membrane in such manner that there are two non-coated ends on said basic membrane and coating the oily ink on said stripping membrane and said non-coated ends.

Owner:TDK CORPARATION

Method for recycling catalyzer from membrane electrode

ActiveCN101130192AThe stripping method is simpleFuel cells disposal/recyclingSolid waste disposalStripping membraneProton

The invention discloses a recycling method of catalyst from membrane electrode, which comprises the following steps: contacting the membrane electrode and solvent to swell the base material; stripping base material of membrane electrode; recycling catalyst from membrane electrode with base material stripped; making the base material of membrane electrode as proton exchange film as macromolecular material. The invention can strip membrane electrode form base material completely to recycle, which simplifies the stripping course.

Owner:BYD CO LTD

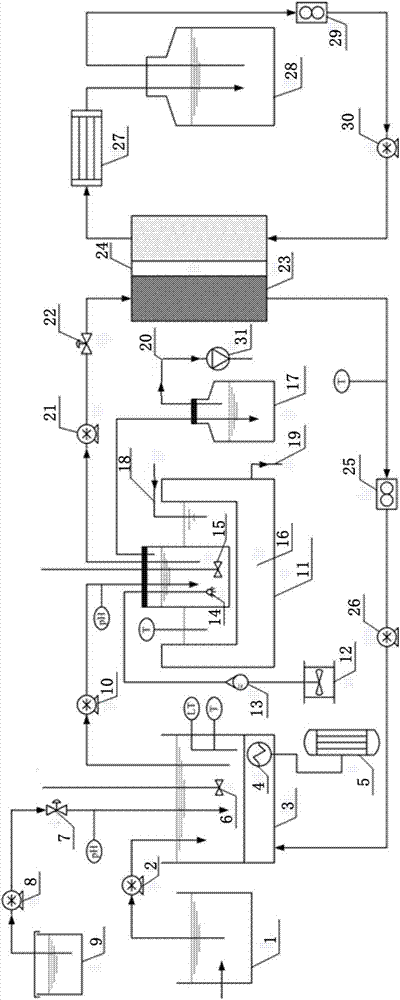

Ultrasonic stripping-membrane distillation technology combined landfill leachate treatment system and method

InactiveCN107473481AReduce concentrationHighly purified effluent qualityWater treatment parameter controlWater/sewage treatment with mechanical oscillationsHydrogenStripping membrane

The invention discloses an ultrasonic stripping-membrane distillation technology combined landfill leachate treatment system and method. The system comprises an ultrasonic stripping tank and a membrane distillation system, wherein the membrane distillation system comprises a first sewage pump, a membrane distillation heating tank, a membrane distillation reactor, a condenser and a clean water tank which are connected in sequence; the ultrasonic stripping tank is located between the membrane distillation heating tank and the membrane distillation reactor; the ultrasonic stripping tank, the membrane distillation heating tank and the membrane distillation reactor are connected in sequence through pipelines to from a circulating loop; the membrane distillation reactor, the condenser and the clean water tank are connected in sequence through pipelines to from a circulating loop; the method comprises the following steps: introducing landfill leachate into the membrane distillation heating tank; after raising the temperature, regulating the pH (Potential of Hydrogen) value; the introducing the landfill leachate into the ultrasonic stripping tank and pre-treating; then introducing the landfill leachate into the membrane distillation reactor and further carrying out purification treatment. According to the ultrasonic stripping-membrane distillation technology combined landfill leachate treatment system and method, the removing rate of ammonia nitrogen in the landfill leachate reaches 99 percent or more and water is highly purified; the limitation of a membrane distillation technology on ammonia nitrogen interception is made up.

Owner:HOHAI UNIV

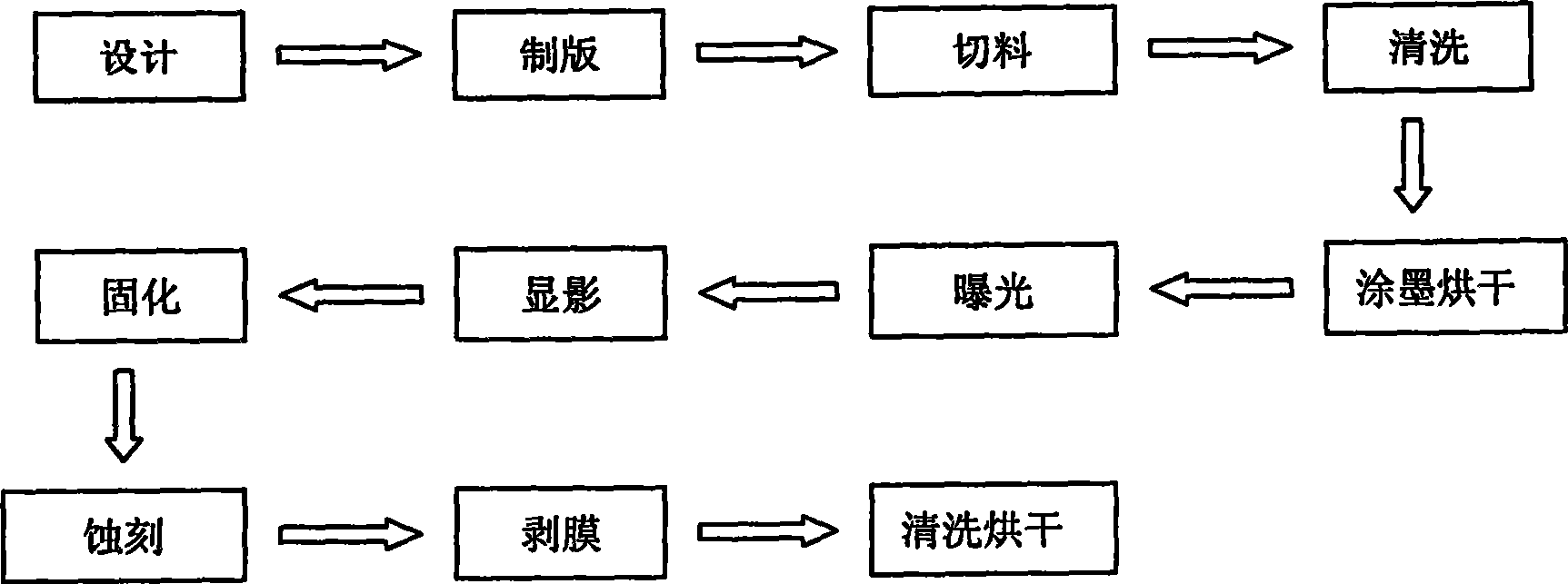

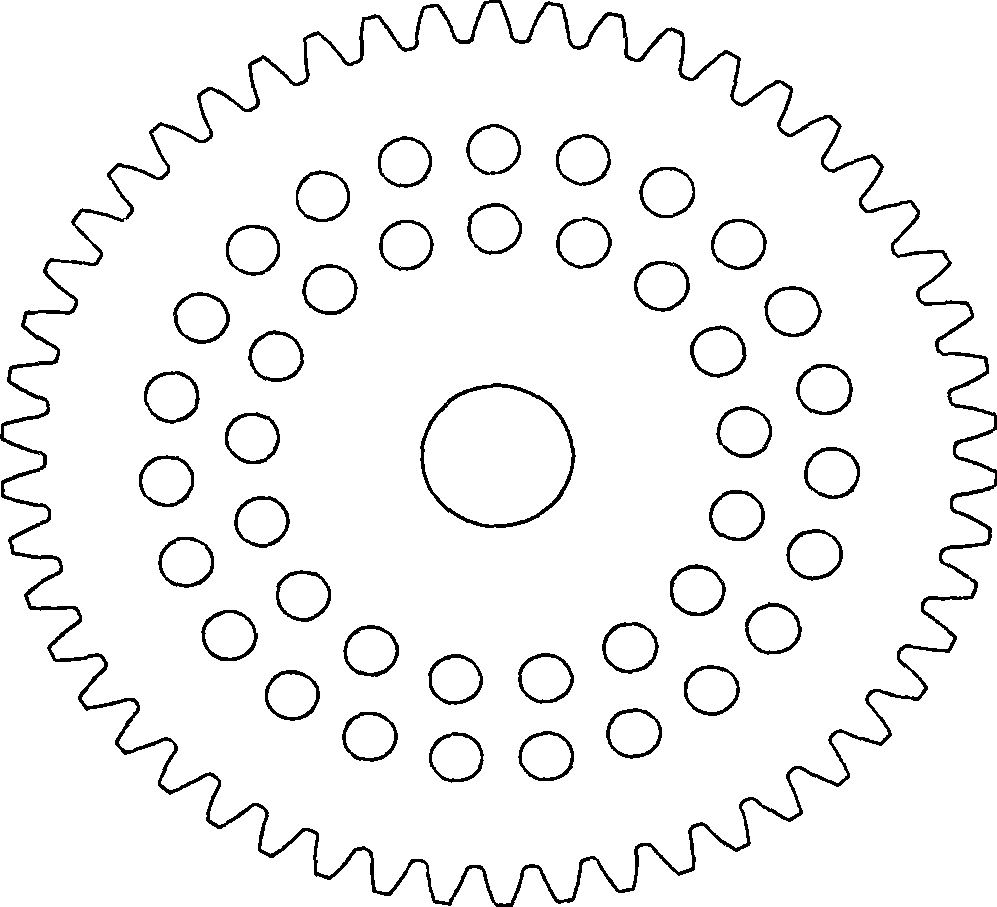

Production process of Planetary gear sheet etching method

InactiveCN101377619AImprove machining accuracyProduct with smooth edgesPhotomechanical apparatusPortable liftingEtchingStripping membrane

The present invention relates to an etching production technology of a wandering star wheel sheet, which comprises the process of the design, plate making, feeding, washing, ink coating, drying, exposure, developing, curing, etching, stripping membranes, cleaning, inspection and packaging. The present invention aims to provide an etching production technology of the wandering star wheel sheet; the precise etching method is adopted; the processing precision of the wandering star wheel sheet is high; the edges of the product are relatively smooth; the yield rate of the wandering star wheel sheet is improved; and the production cost is reduced. Because the present invention is suitable for medium- and small-scale production and has excellent consistency, the traditional blanking processing method for fine parts can be replaced by the etching production technology of the wandering star wheel sheet.

Owner:CAIHONG GRP ELECTRONICS CO LTD

Method for recycling catalyzer from membrane electrode

ActiveCN101130192BThe stripping method is simpleFuel cells disposal/recyclingSolid waste disposalStripping membraneProton

The invention discloses a recycling method of catalyst from membrane electrode, which comprises the following steps: contacting the membrane electrode and solvent to swell the base material; strippingbase material of membrane electrode; recycling catalyst from membrane electrode with base material stripped; making the base material of membrane electrode as proton exchange film as macromolecular material. The invention can strip membrane electrode form base material completely to recycle, which simplifies the stripping course.

Owner:BYD CO LTD

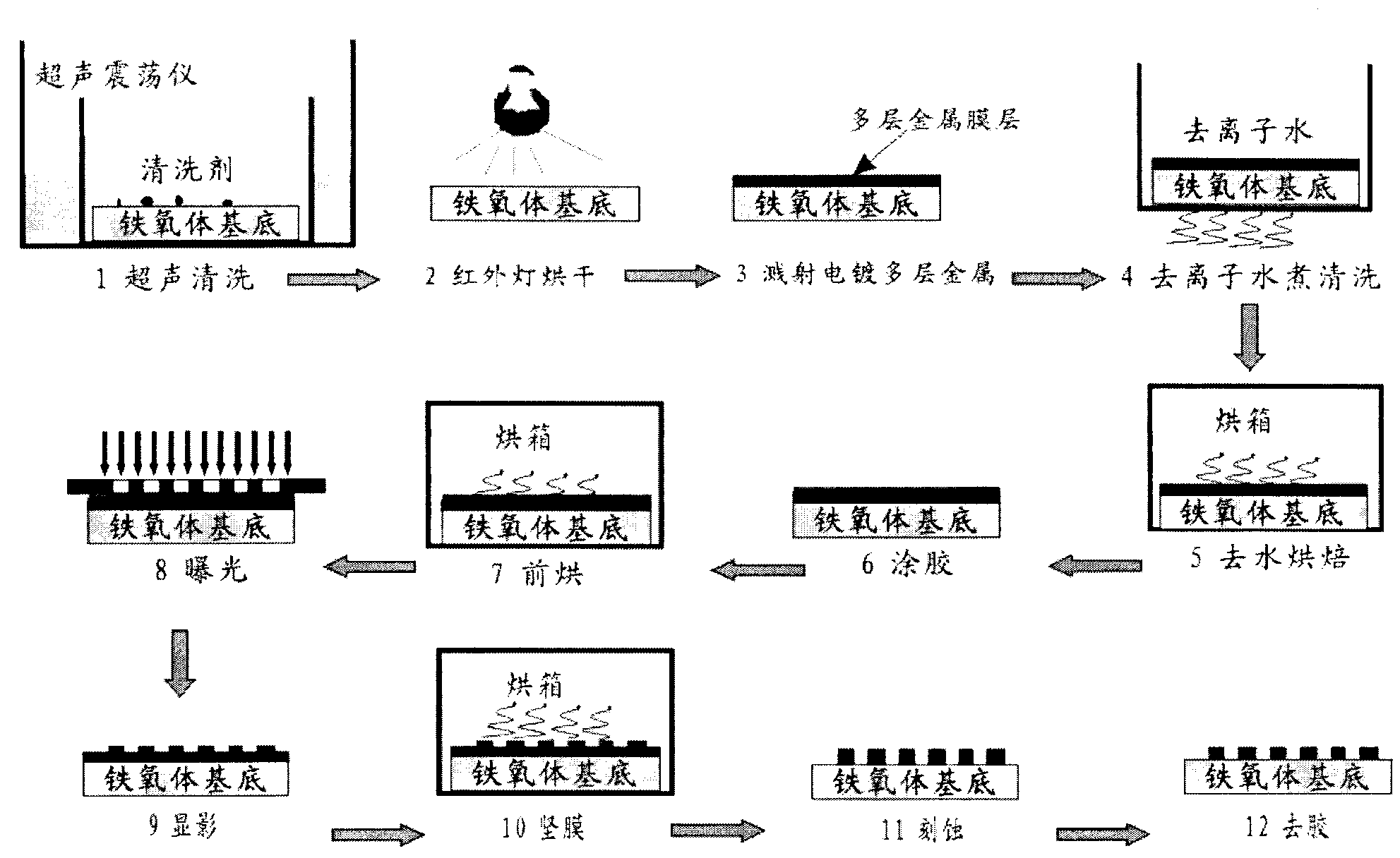

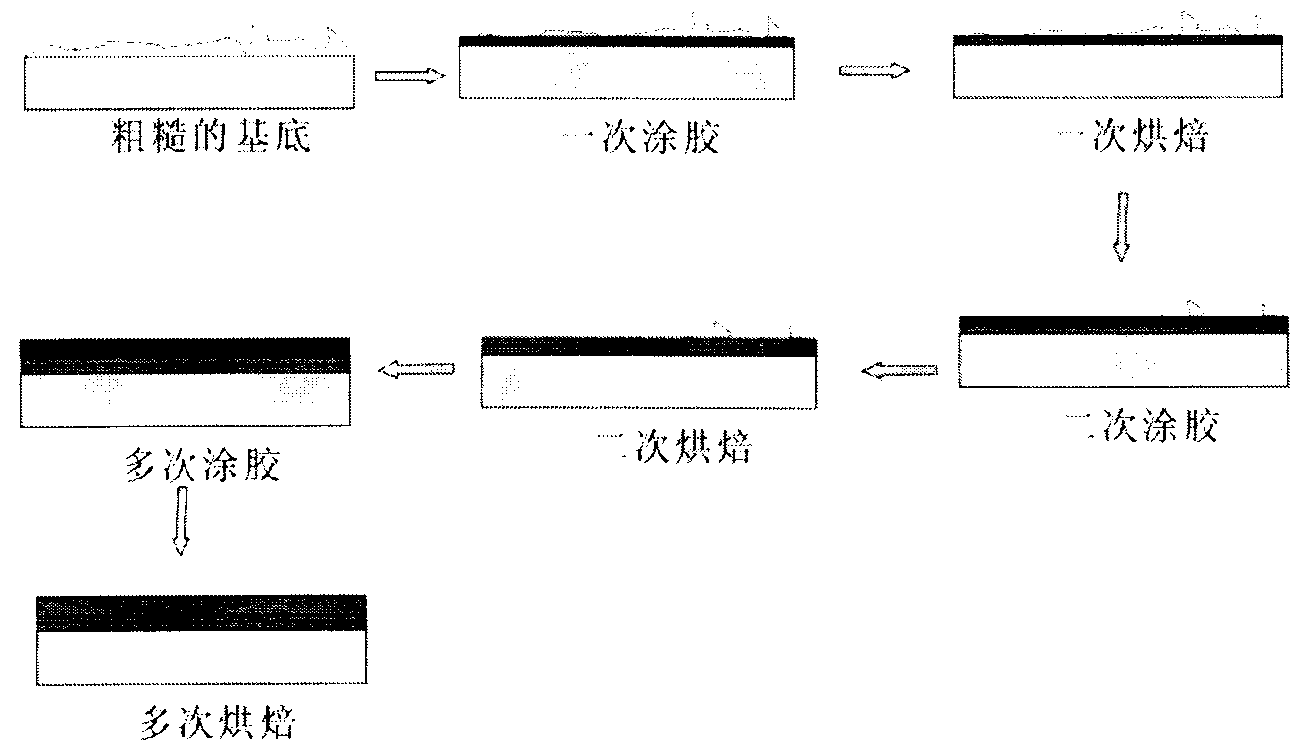

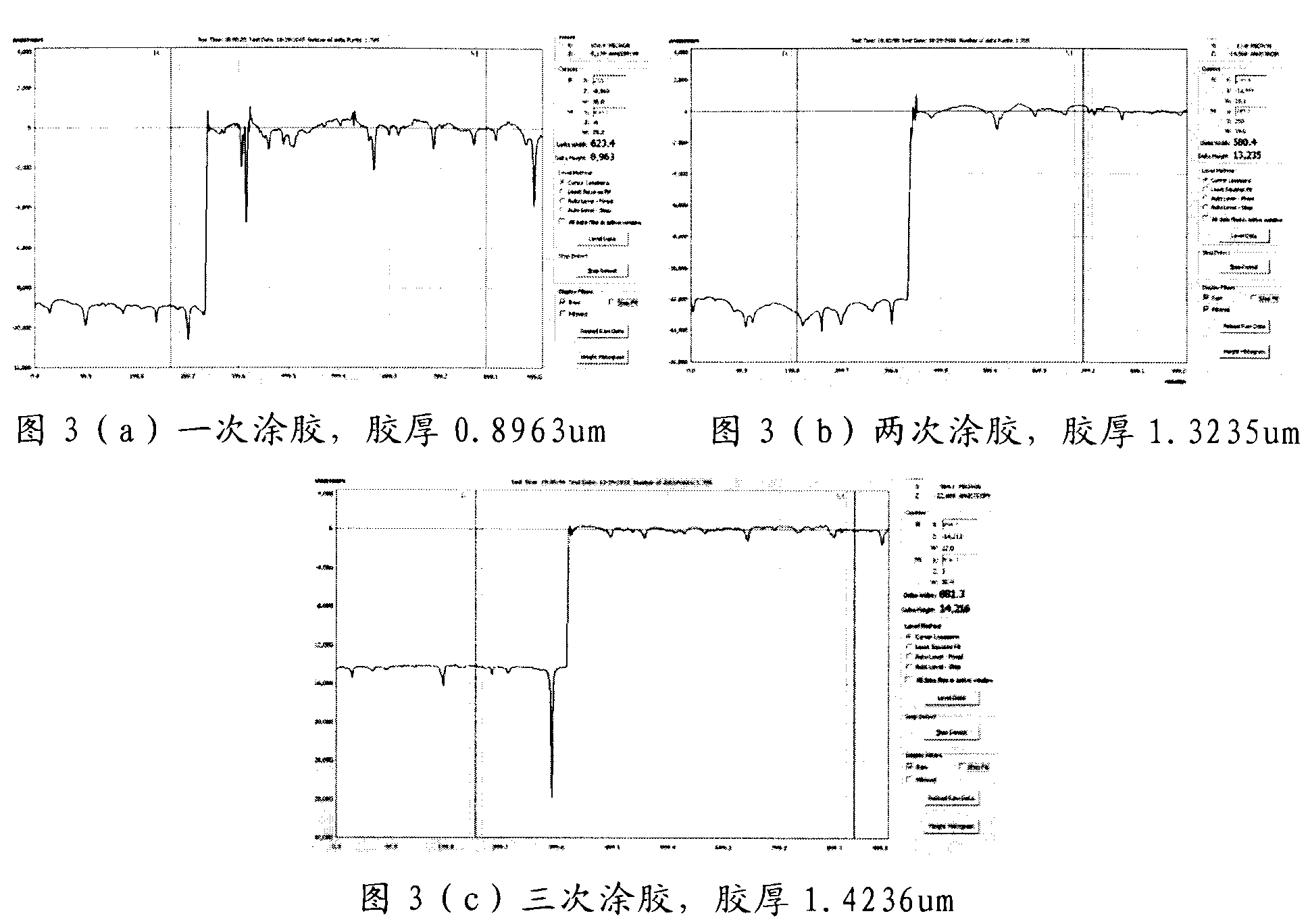

Efficient photoetching manufacturing method of ferrite base membrane circuit

InactiveCN102856245AIncreasing the thicknessStrong corrosion resistanceSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistManufacturing technology

The invention provides an efficient photoetching manufacturing method of a ferrite base membrane circuit. The efficient photoetching manufacturing method comprises the steps of: (1) selecting a proper ferrite base material according to the requirement of a prepared device as expected; carrying out metalizing, washing and drying on a base; (2) repeatedly gluing and baking the ferrite base which is cleaned and coated with a metal membrane layer, so as to obtain an uniform and dense slushing compound layer which can well protect metal at the bottom layer on a ferrite base sheet; (3) exposing and developing the baked slushing compound to obtain a circuit pattern of the slushing compound; and (4) transmitting the circuit pattern of the slushing compound on the metal through using a wet etching way or dry etching way, so as to achieve the manufacture of the ferrite base micro-strip membrane circuit. The invention provides a method for repeatedly gluing and baking a ferrite base, and therefore, the coated slushing compound layer is uniform and is good in compactness, and the problem that the slushing compound is hardly uniformly coated during photoetching due to the shortcomings that the ferrite base is coarse, porous and the like can be solved; the probability that a pin hole, a sand hole and the like are generated can be reduced, and thus, the steps of manually repairing the pattern in the conventional ferrite membrane circuit manufacture technology can be removed; and as a result, the technological stability and the manufacture efficiency of a ferrite base membrane device can be greatly improved.

Owner:中国电子科技集团公司第九研究所

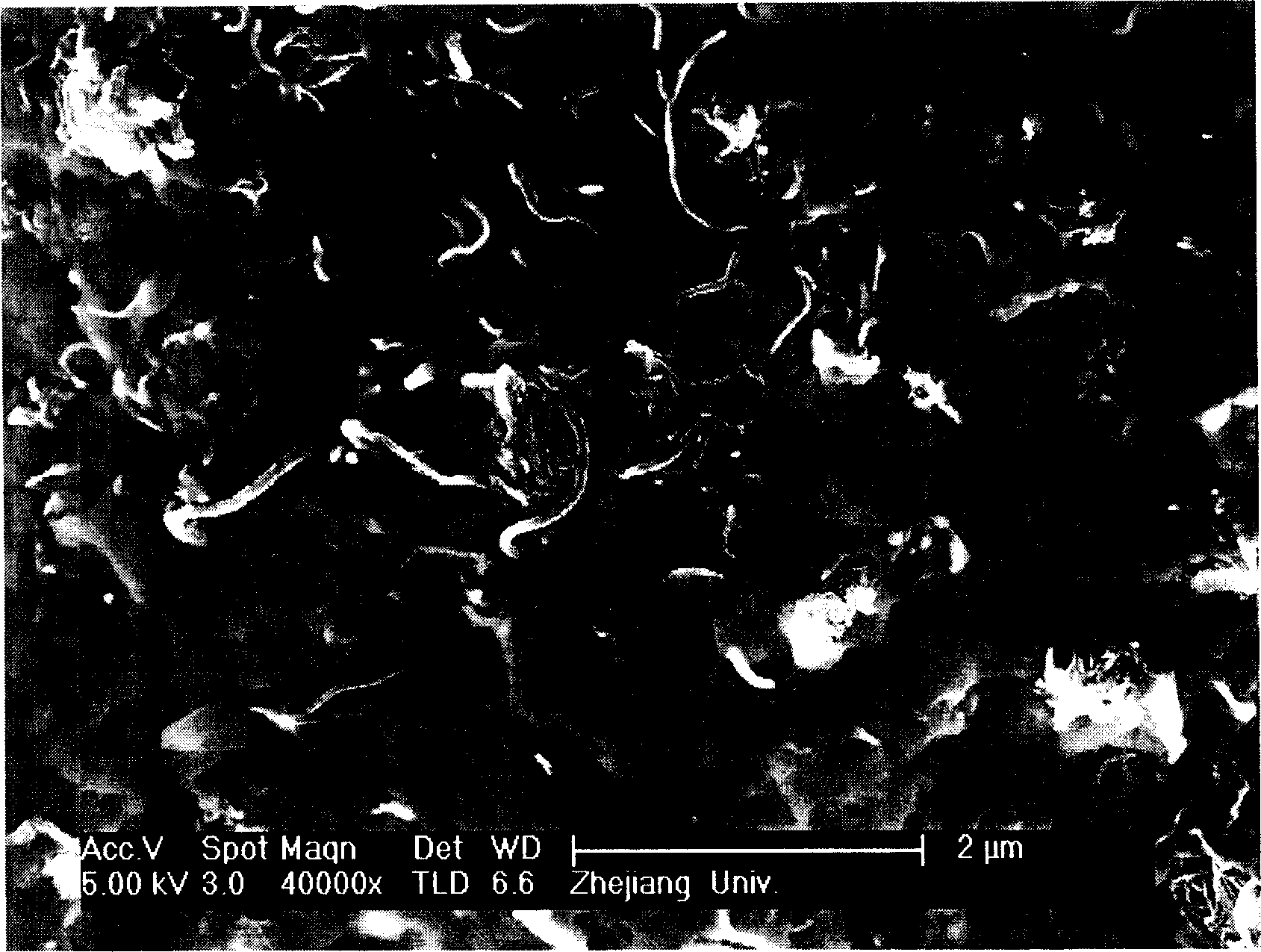

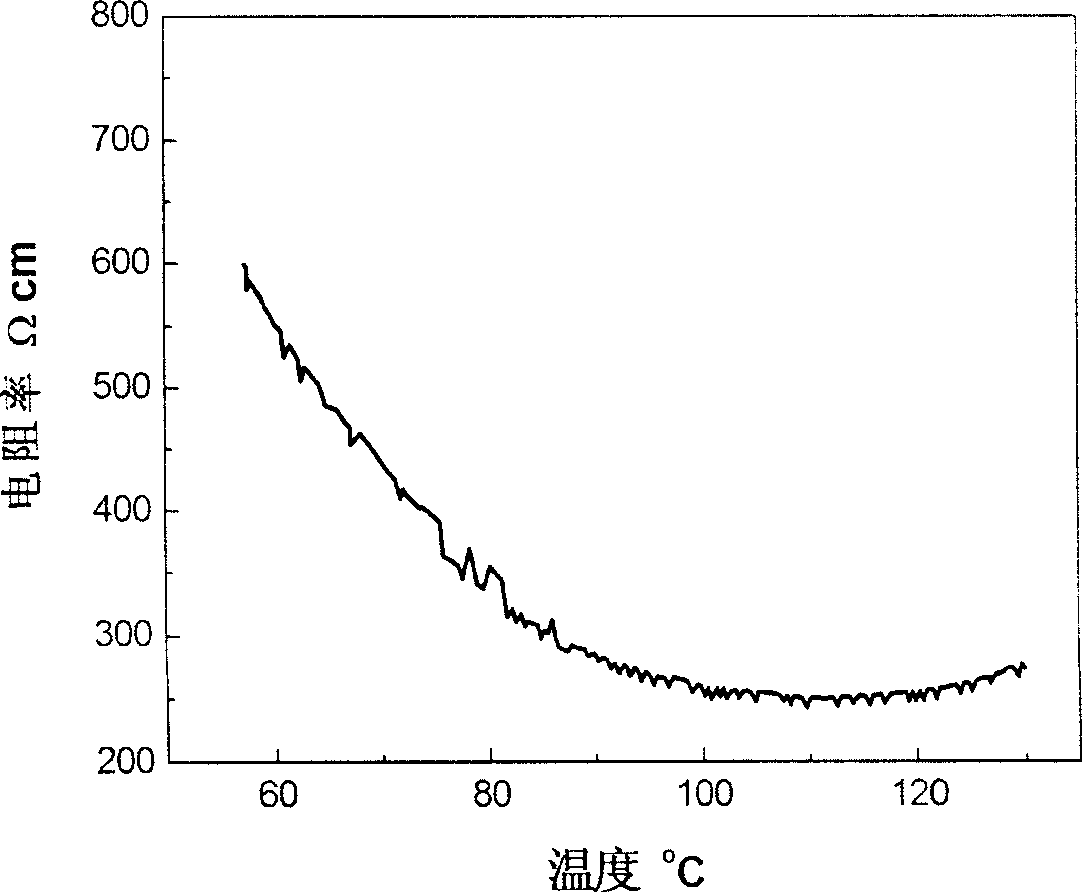

Electric heating composite material for temperature measurement and preparation method thereof

InactiveCN1877273ASimple processEasy to operateThermometers using electric/magnetic elementsUsing electrical meansElectricityStripping membrane

The invention discloses an electrical heating compound material for measuring temperature, which comprises 6~9% weight percentage multi-walled carbon nanotubes, 91~94% weight percentage high density polyethylene. The method for making the compound material comprises: weighing multi-walled carbon nanotubes powder and high density polyethylene in proportion; mixing them and placing them into a model; pre-heating 5~20 minutes in 165~180 centigrade, pressing 5~20 minutes under 5~30 MPa pressure; stripping membrane and cooling to room temperature. The inventive compound material takes high density polyethylene as base, multi-walled carbon nanotubes as additive, which make the compound material has great conductivity and electrical heating performance and be used to temperature measurement in a certain temperature range.

Owner:ZHEJIANG UNIV

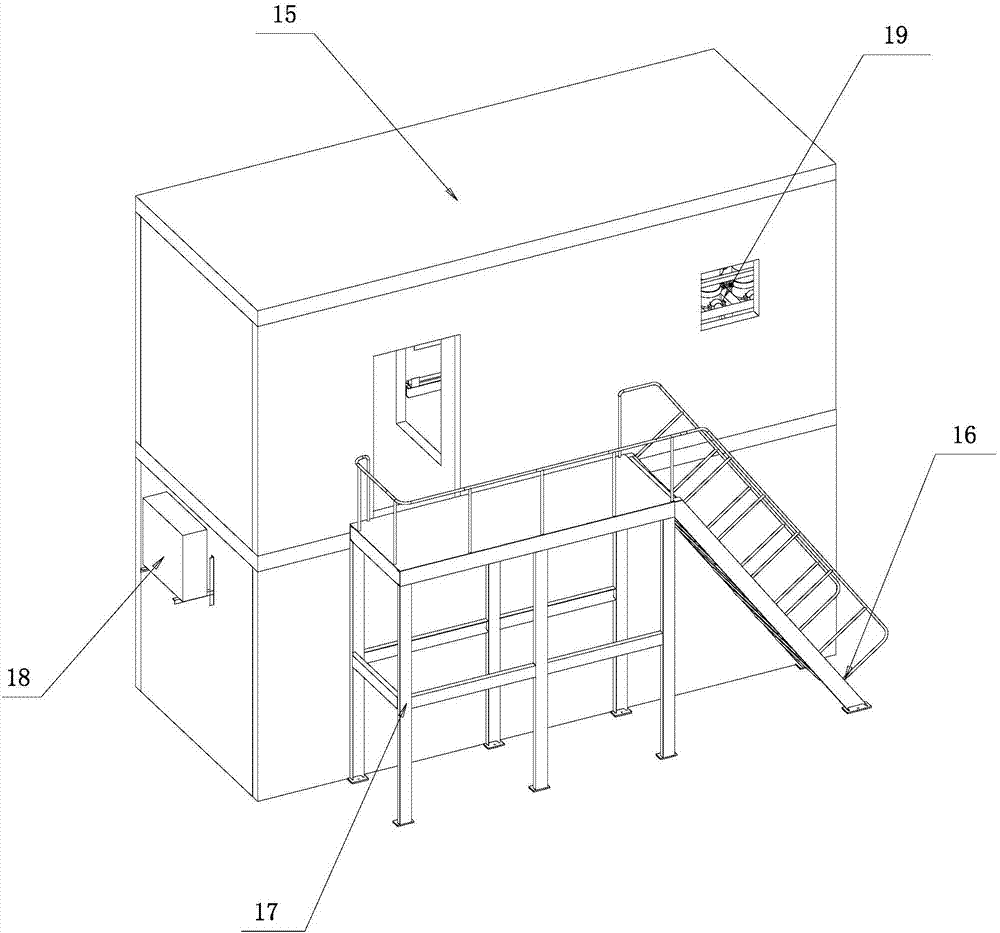

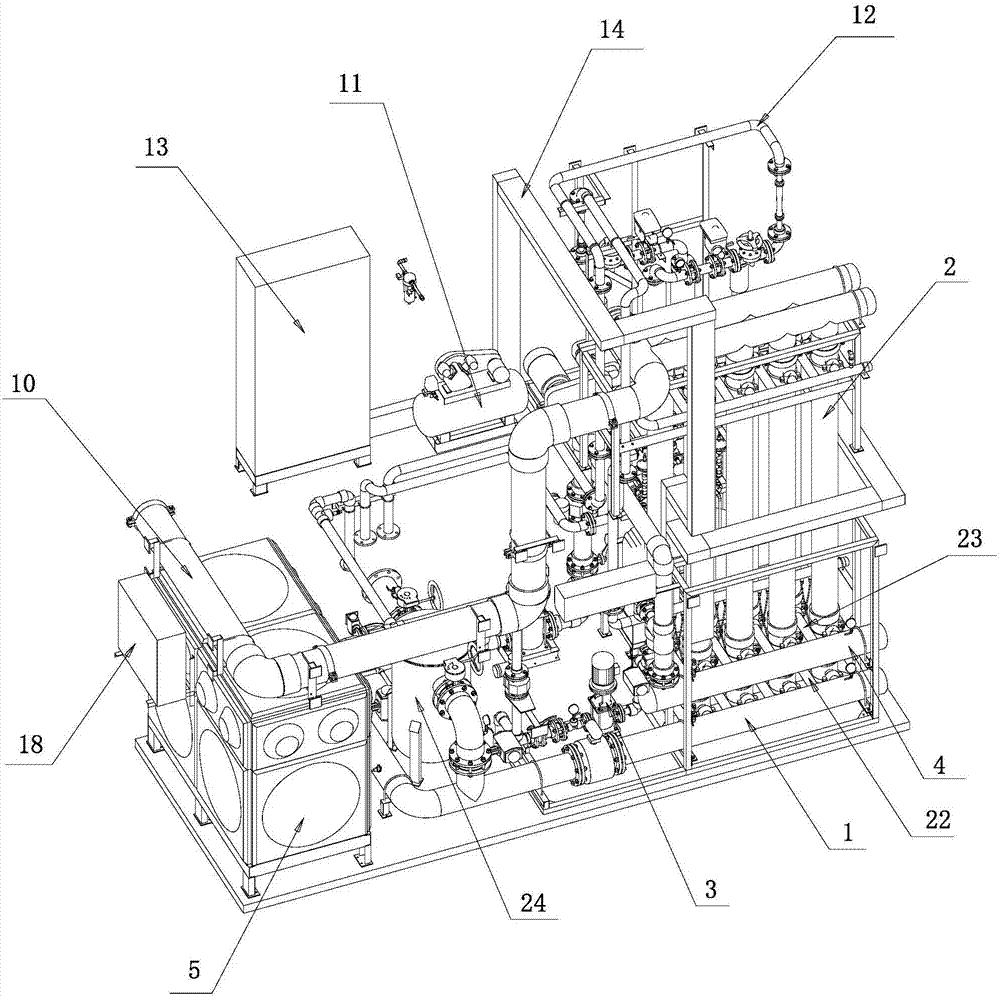

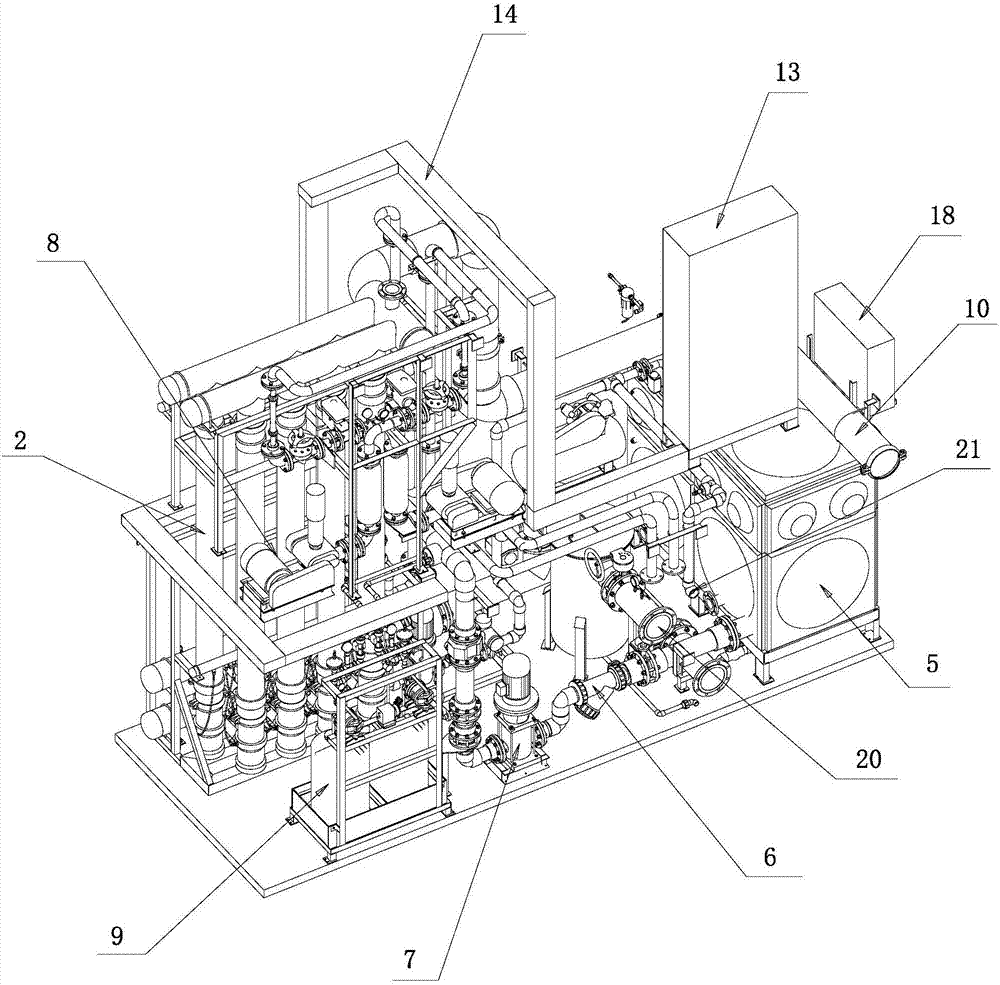

Split-type air stripping membrane reactor treatment device

PendingCN107226522AExtend your lifeIncrease profitSemi-permeable membranesTreatment using aerobic processesInternal pressureSludge

The invention discloses a split-type air stripping membrane reactor treatment device. The split-type air stripping membrane reactor treatment device comprises a split-type machine cabinet, an air stripping membrane reactor membrane group, a water inlet system, a produced water system, a backwashing system, a self-use water tank, a control system and a sludge reflowing pipeline, wherein the front end and the back end of the water inlet system are communicated with a biological reaction system and the air stripping membrane reactor membrane group; the front end and the back end of the produced water system are communicated with the air stripping membrane reactor membrane group and a produced water tank; the front end and the back end of the backwashing system are communicated with the self-use water tank and the air stripping membrane reactor membrane group; the control system is connected with the other systems; the sludge reflowing pipeline is communicated with the biological reaction system; the air stripping membrane reactor membrane group comprises at least one internal pressure-type pressure container; at least ten membrane filaments are vertically arranged inside the pressure container. The split-type air stripping membrane reactor treatment device is simple in structure and strong in sewage treatment capacity, guarantees the pollutant intercepting uniformity of the membrane filaments in each membrane element, prolongs the service life of the membrane element and reduces the operating expense.

Owner:GREENTECH ENVIRONMENTAL CO LTD

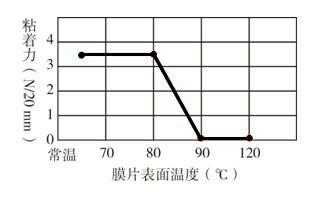

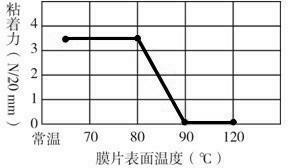

Production process of temperature-sensitive stripping membrane

InactiveCN102676074AIncrease profitAvoid traditional cleaning operationsNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterAdhesive belt

The invention discloses a production process of a temperature-sensitive stripping membrane. The production process comprises the following steps of: A, producing a temperature-sensitive stripping bonding agent; B, processing a stripping layer: coating organic silicon oil onto one face of a polyester film to obtain a stripping layer; C, coating a temperature-sensitive stripping layer: coating the temperature-sensitive stripping layer bonding agent onto one surface of a substrate; and D, compounding and calendaring: compounding and calendaring the stripping layer onto the substrate which is coated with the temperature-sensitive stripping bonding agent, bonding one surface of the stripping layer which is coated with organic silicon oil with one surface of the substrate which is coated with the temperature-sensitive stripping bonding agent, and coiling. The production process has the advantages: during use, a special temperature-sensitive stripping bonding agent is foamed by heating to a specified temperature, and adhesive force of an adhesive belt disappears instantly, so that stripping is realized. Natural stripping can be realized without stressing, so that workpieces are not damaged or polluted, labor face is saved, conventional cleaning operation is avoided, and the utilization ratio of raw materials is increased.

Owner:荆门市维益电子包装材料有限公司

Fan-out high-density packaging method

ActiveCN102157393BLess distracting factorsComply with the trend of light, thin and shortSolid-state devicesSemiconductor/solid-state device manufacturingElectricityStripping membrane

The invention relates to a fan-out high-density packaging method, which comprises the following steps of: providing a carrier plate; forming a stripping membrane on the carrier plate; forming protective layers on the stripping membrane; forming a rewiring metal layer in the protective layers; forming wiring packaging layers which are conductive with the rewiring metal layer on the protective layers; forming inversion packaging layers on the wiring packaging layers, wherein the packaging layers are connected electrically and mutually by wiring layers and welding flux salient points; removing the carrier plate and the stripping membrane, so that rewiring metal in a first protective layer is exposed; and forming a metal welded ball on the exposed rewiring metal. Compared with the prior art, the fan-out high-density packaging method has the advantages that: a final packaging product with an integral systemic function instead of a single chip function can be formed, and the resistance and inductance in a system and interference factors among chips are reduced. In addition, a complex multi-layer interconnection structure can be formed, so that the wafer system-level packaging of a higher integration level is realized.

Owner:NANTONG FUJITSU MICROELECTRONICS

Traditional Chinese medicine compound recipe for treating hyperplasia of mammary glands and preparation method thereof

The present invention discloses compound Chinese medicine preparation for treating hyperplasia of mammary glands and its preparation process and quality control method. The compound Chinese medicine is prepared with green tangerine orange peel, bupleurum root, fried cowherb seed, burreed rhizome, zedoary and other six kinds of Chinese medicinal materials, and through alcohol extraction, concentration, adding supplementary material, heating to dissolve and obtain extractum, painting, and stripping membrane as the adhered membrane. The present invention also provides the quality control method including component identification and content measurement. The membrane of the present invention has the functions of inhibiting hyperplasia, removing blood stasis, dissipating mass, relieving pain, lowering estradiol content in blood serum and plasma viscosity and reducing platelet aggregation and is effective medicine for hyperplasia.

Owner:YANTAI RONGCHANG PHARMA

Organic-inorganic compoiste proton exchange film and preparing method

InactiveCN100499238CReduce penetrationIncrease profitCell electrodesSolid electrolyte fuel cellsPolymer scienceOrganic solvent

In the method, sulfonated polymer is dissolved in organic solvent. Added organic modified montorillonite clay is dispersed on basal body of polymer evenly. Membrane is formed through slobbering method. Through drying and stripping membrane in water produces membrane needed. Solving difficult problem of methanol infiltration of proton exchange membrane in use for direct fuel cell of methanol, the invention possesses features of simpler technique, and low cost of material etc.

Owner:SOUTH CHINA UNIV OF TECH

Coating method for bicycle

InactiveCN1250345CGood broken color effectClear paragraphs in colorPretreated surfacesCoatingsStripping membraneEngineering

The coating method for bicycle is characterized by that it utilizes the decal paper formed from protective layer, stripping membrane layer, printing ink layer and base paper, and adopts the steps of soaking in clear water, scouring and scraping with clear water and progressively high-temp. baking, and spraying oil so as to obtain excellent coating effect, and the characters, brand and pattern have strong adhesive force and strong wear resistance.

Owner:刘国彰

Fan-out system-in-package (SIP) method

ActiveCN102176418BLess distracting factorsComply with the trend of light, thin and shortSolid-state devicesSemiconductor/solid-state device manufacturingInterference factorSystem in package

Owner:NANTONG FUJITSU MICROELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com