Production process of temperature-sensitive stripping membrane

A production process and release film technology, applied in the direction of film/sheet adhesive, adhesive type, amide/imide polymer adhesive, etc., can solve the leakage of temperature-sensitive release film production technology, etc. problems, to avoid cleaning operations, improve utilization, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

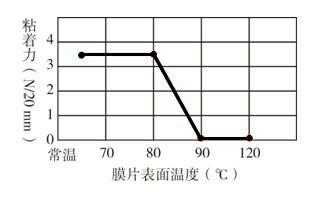

Image

Examples

Embodiment Construction

[0017] Production process step of the present invention is:

[0018] A. Production of temperature-sensitive release adhesives; temperature-sensitive release adhesives are multi-component acrylate copolymer emulsions; 85 kg of alkoxysilane acrylate or methylol acrylamide mixed monomers, imidazole curing catalysts or polyisocyanate high temperature Curing agent 3kg, azodicarbonamide or p-toluenesulfonic acid hydrazide foaming agent 4kg, plastic antioxidant (commercially available product, select compound antioxidant: hindered phenol compound with phosphite, thioester) material) 0.3kg, plasticizer (for commercially available products, choose electrical grade dioctyl phthalate) 0.3kg and mix well to form a temperature-sensitive peeling adhesive, and fillers (light calcium carbonate or talc can also be added Powder) 0.3kg and an appropriate amount of coloring material.

[0019] B. Coating the peeling layer: coating the silicone oil on one side of the polyester film is the peeling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com