Manufacturing process of single panel gold finger

A manufacturing process and gold finger technology, applied in the field of single-panel gold finger manufacturing process, can solve problems such as fracture, low production yield, wrinkle, etc., and achieve the effect of wide application range and improved production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

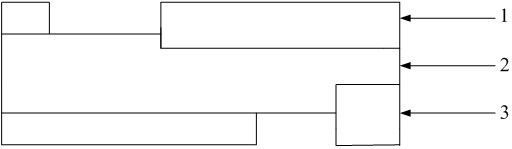

[0022] figure 1 1 is the top cover film layer, 2 is the pure copper foil layer, and 3 is the bottom cover film layer.

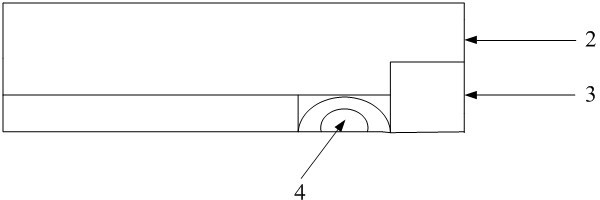

[0023] figure 2 2 is the pure copper foil layer, 3 is the bottom cover film layer, and 4 is the high temperature resistant PI tape. Paste 4 on the window opening of the bottom cover film of 3, laminate with 2, and then laminate and press on the copper foil, tear off 4 after pressing, and then cover the top cover film layer 1 and the bottom layer Surface treatment is carried out at the window opening of the film layer 3 until the product is molded and packaged for shipment.

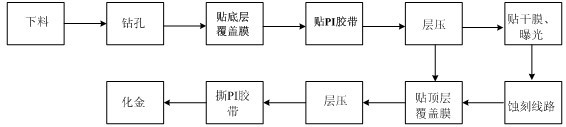

[0024] Such as image 3 As shown, it is the manufacturing process of the single-sided gold finger in the present invention. The gold finger includes: a top cover film layer 1 arranged on the upper layer, a pure copper foil layer 2 in the middle, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com