Fast preparation method of wound lithium-ion laminated battery

A lithium-ion, wound-type technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of low production efficiency and complicated preparation process of laminated batteries, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

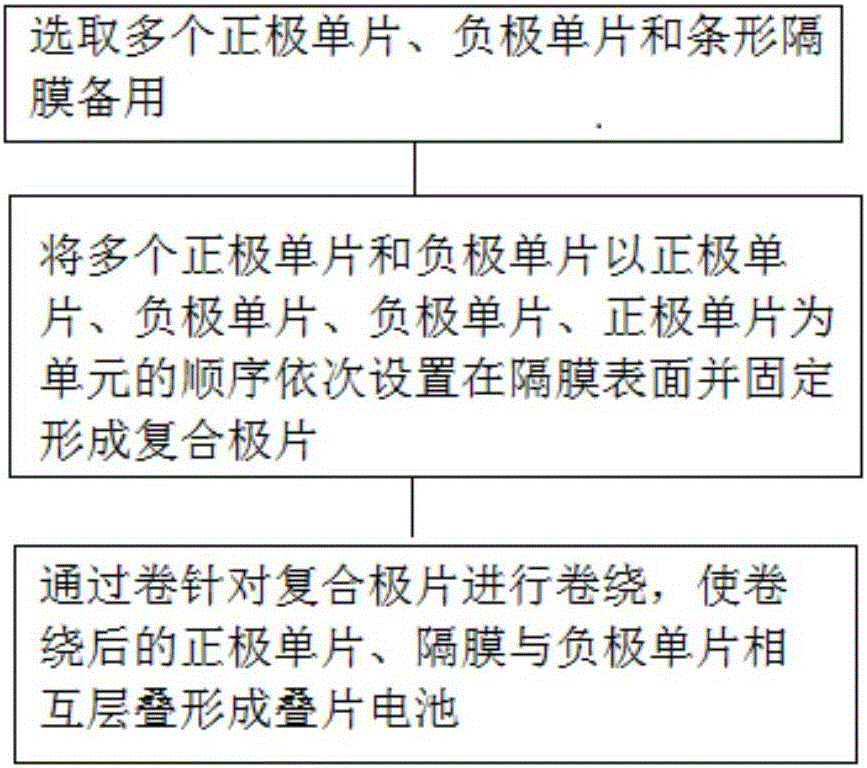

[0019] like figure 1 Shown, a kind of rapid preparation method of winding type lithium-ion lamination battery, comprises the following steps:

[0020] S1: select a plurality of cut positive electrode monoliths 16, negative electrode monoliths 17 and strip-shaped glue-coated separators 18 for use;

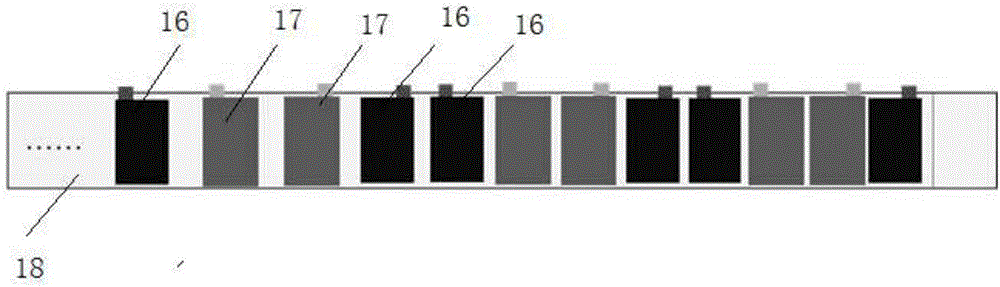

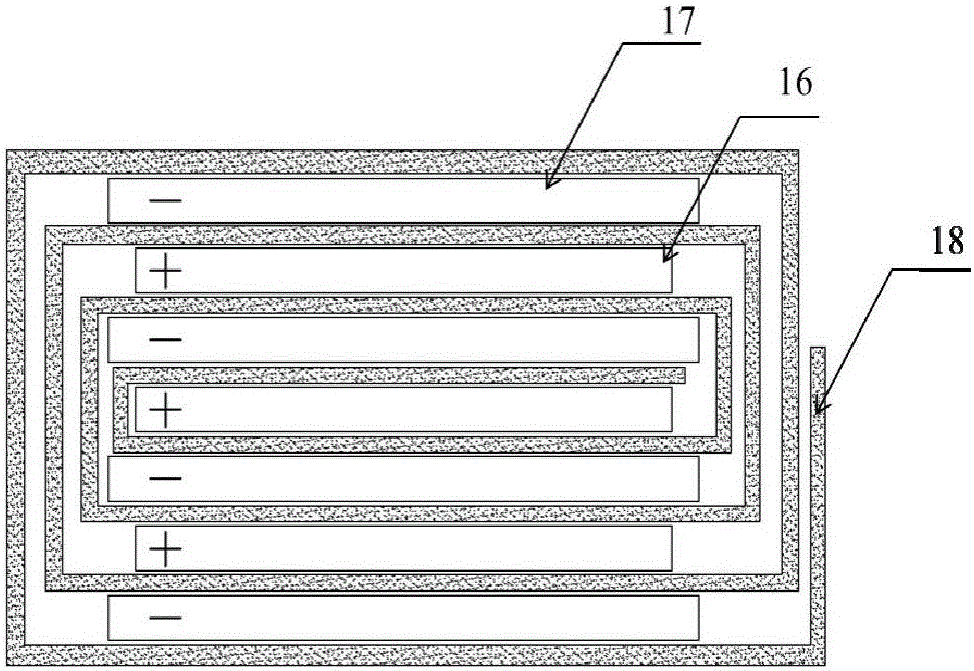

[0021] S2: A plurality of positive pole single pieces and negative pole single pieces are arranged in the order of positive pole single piece 16, negative pole single piece 17, negative pole single piece 17, and positive pole single piece 16 (that is, positive pole single piece 16, negative pole single piece 17, negative pole single piece Monolithic 17, positive electrode monolithic 16, each group of 4 is a sequence of successive cycles, such as figure 2 shown) are arranged on the surface of the diaphragm in turn and fixed to form a composite pole piece. The distance between a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com