Efficient photoetching manufacturing method of ferrite base membrane circuit

A production method and technology of thin film circuits, which are applied in the direction of circuit, pattern surface photolithography process, semiconductor/solid-state device manufacturing, etc., can solve the problems of difficulty in realizing large-scale equipment production, poor process stability, and low yield rate. Achieve the effect of increasing thickness, strong performance and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method will be described in detail below in conjunction with specific implementation methods and accompanying drawings, but the scope of protection of the present invention is not limited to the following examples, and should include all content in the claims. Moreover, those skilled in the art can realize all the content in the claims from the following embodiment.

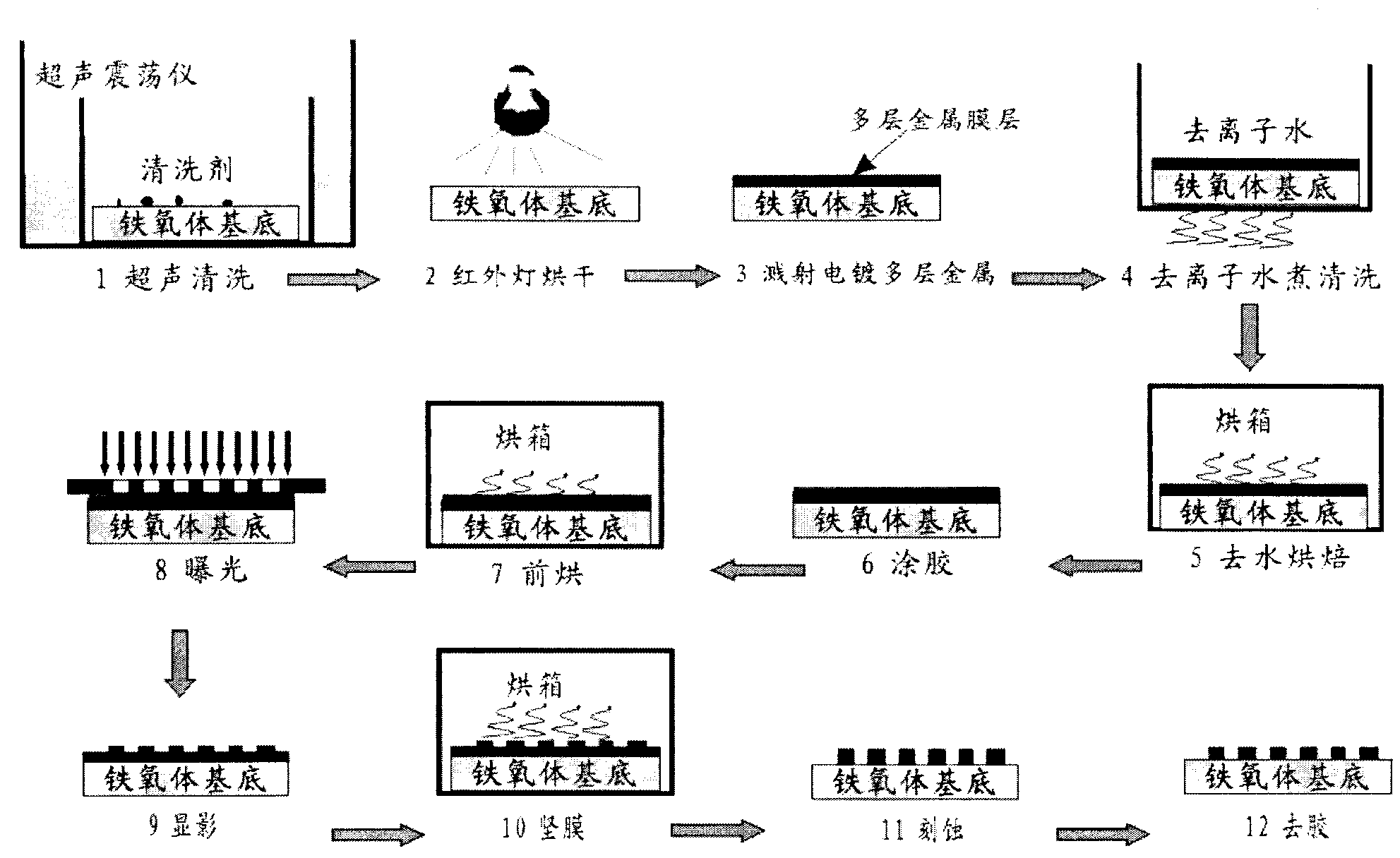

[0021] The specific process of this method embodiment is as follows:

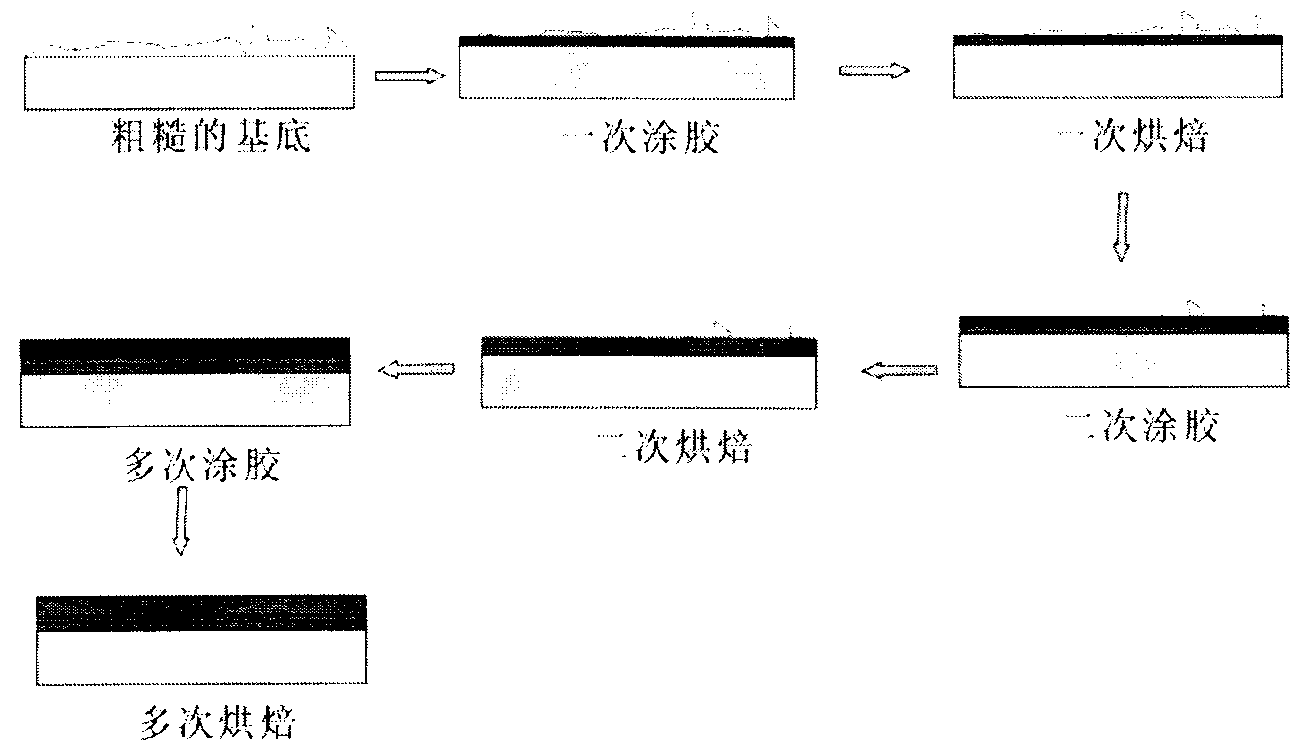

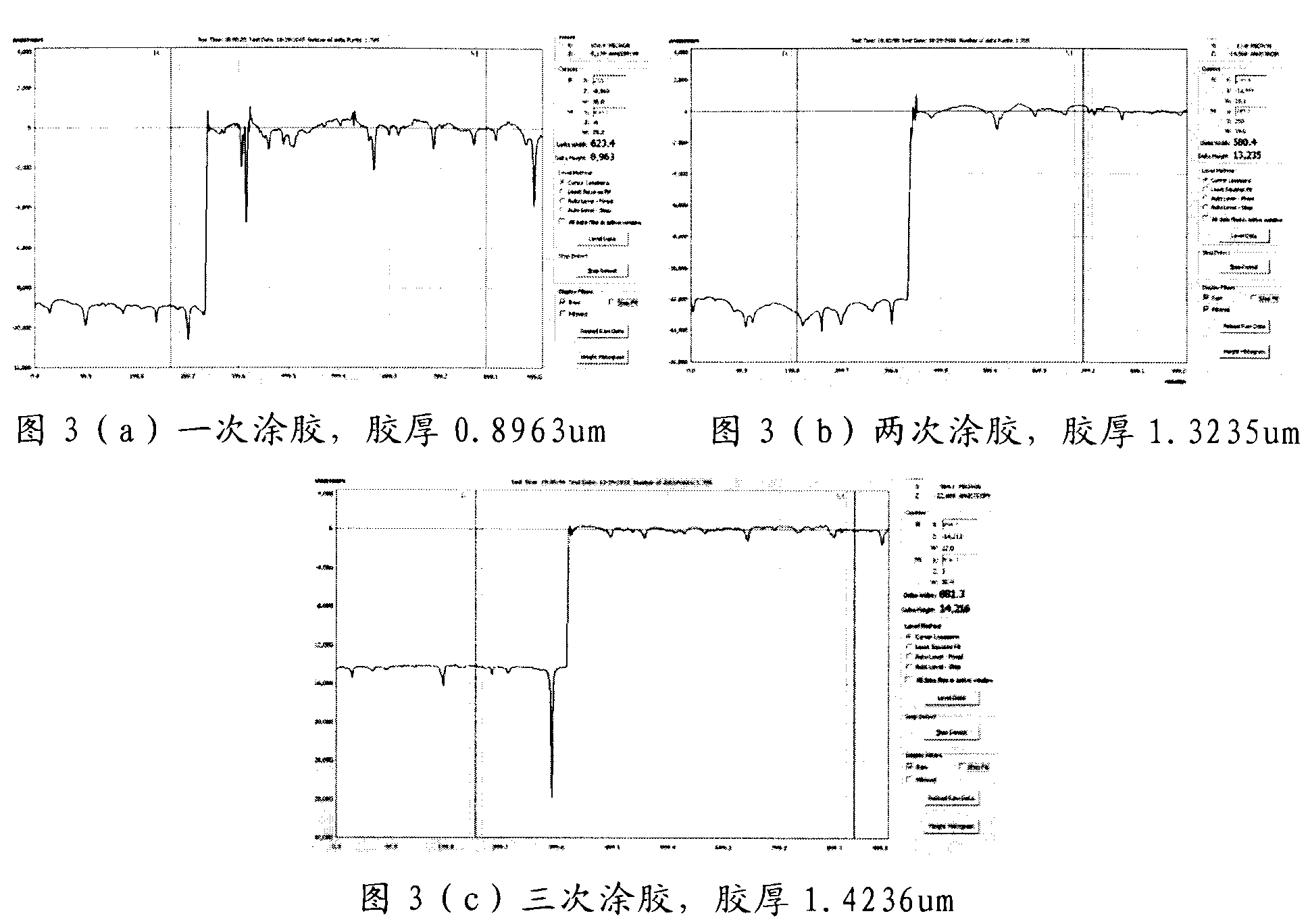

[0022] (1) Select a suitable ferrite substrate material according to the expected preparation of the device, and metallize, clean and dry the substrate. The ferrite substrate needs to be strictly cleaned before sputtering plating, so that the metal film layer is firmly attached to the substrate. The substrate with the metal film before photolithography also needs to be cleaned and removed to prevent the photoresist from being firmly attached to the substrate. , floating glue and other phenomena appear, the drying process needs to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com