Split-type air stripping membrane reactor treatment device

A membrane reactor and processing device technology, which is applied in the field of split-type air-lifting membrane reactor processing device, can solve problems such as difficulty in adapting measures to local conditions, geographical restrictions on installation and use, and restrictions on operating methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

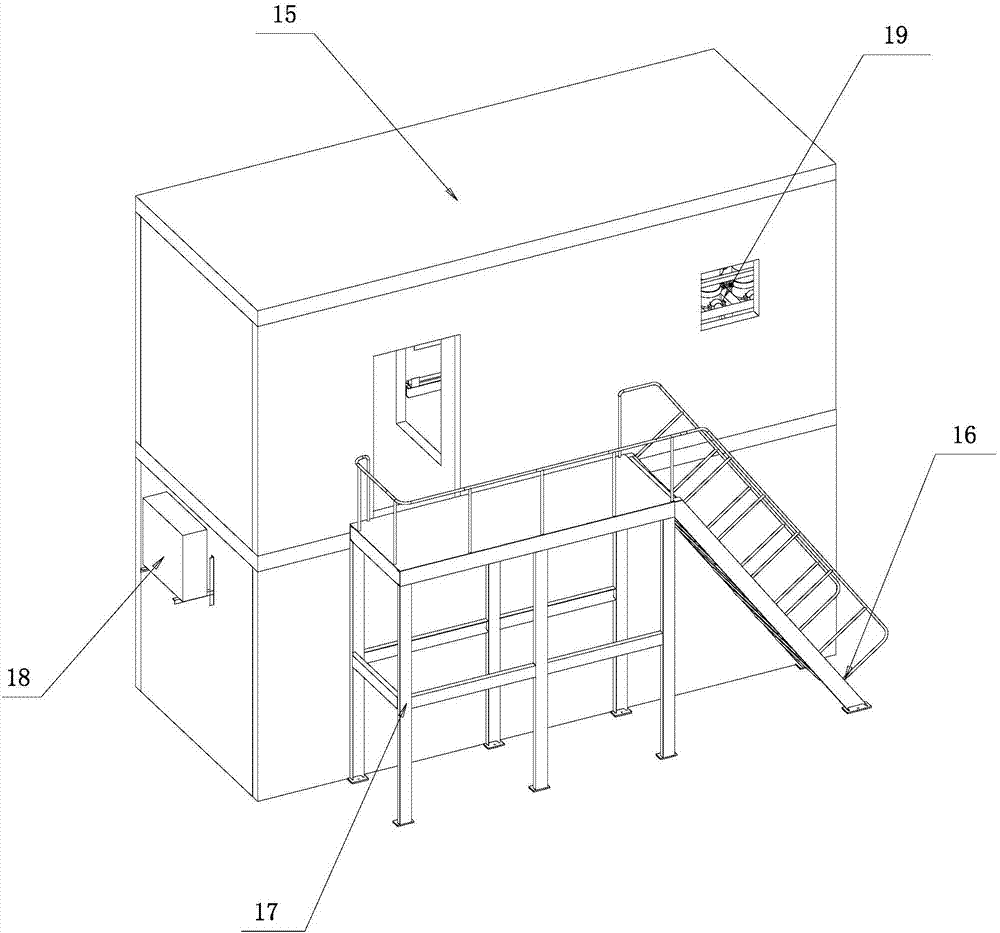

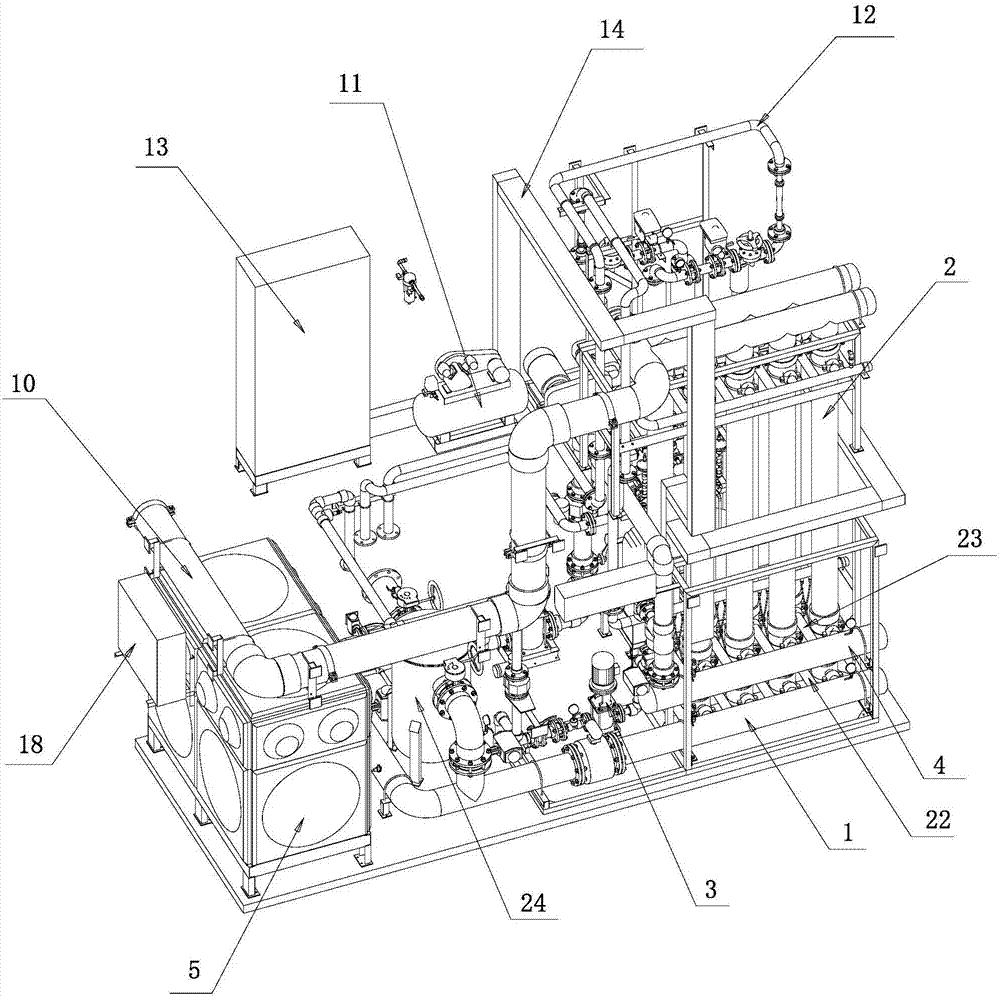

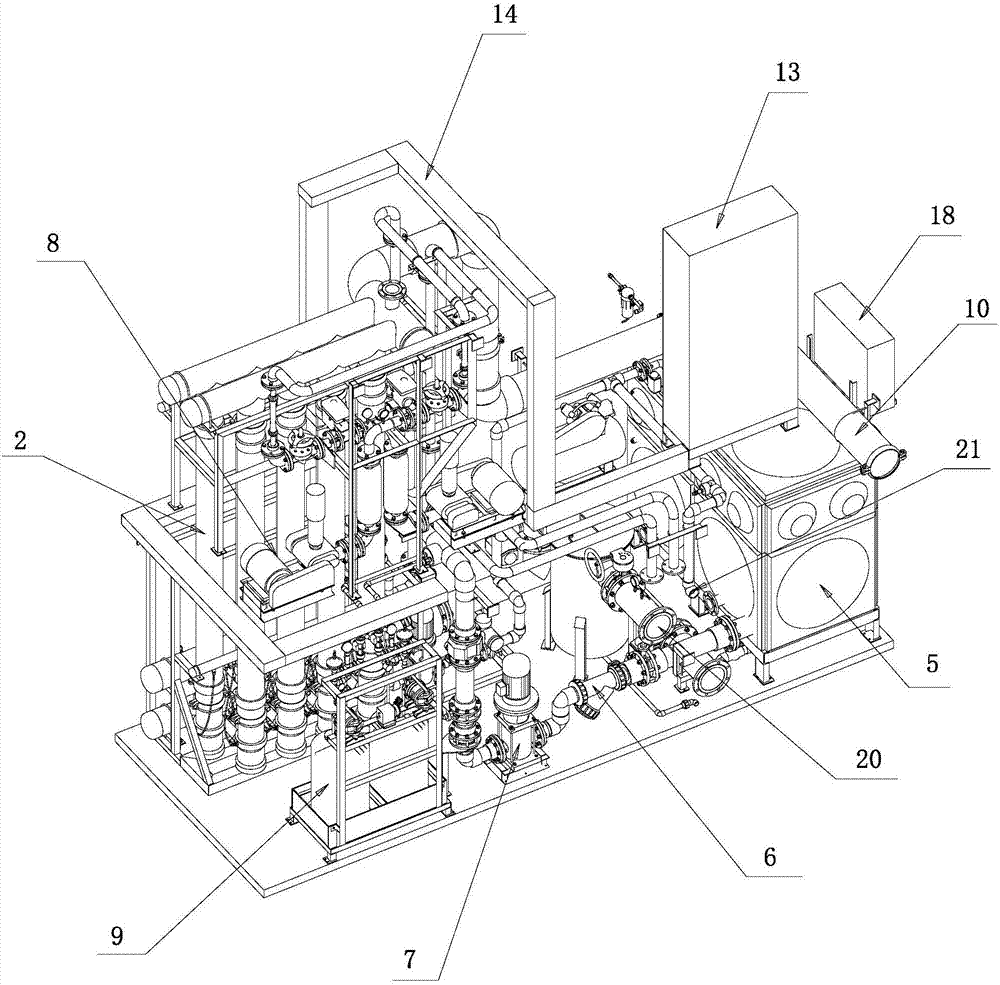

[0033] The following with attached Figure 1 to Figure 3 A split-type air-stripping membrane reactor treatment device of the present invention will be further described in detail.

[0034] A split-type air-lift membrane reactor treatment device of the present invention, please refer to Figure 1 to Figure 3 Relevant figures in the middle include a split cabinet 15 and an air-lift membrane reactor membrane group 2, a water inlet system, a water production system, a backwash system, a self-use water tank 5, a control system 13 and Sludge return pipeline 10, the front end of the water inlet system is in adjustable flow communication with the biological reaction system, and the biological reaction system is provided with a biochemical mixed solution that needs to be purified and mixed with biochemical substances. The end is connected with the membrane group 2 of the air-lifting membrane reactor with adjustable flow rate, and the front and rear ends of the water production system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com