High-barrier thermophilic digestion resistant easy-stripping membrane

A high-temperature-resistant, easy-to-tear film technology, applied in the direction of flexible coverings, packaging, layered products, etc., can solve the technical requirements for sterilization at 121-135°C for 30 minutes, human health damage caused by preservatives, soft bags or Cover film deformation and other problems, to achieve the effect of good heat sealing, reliable sealing, and hygienic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

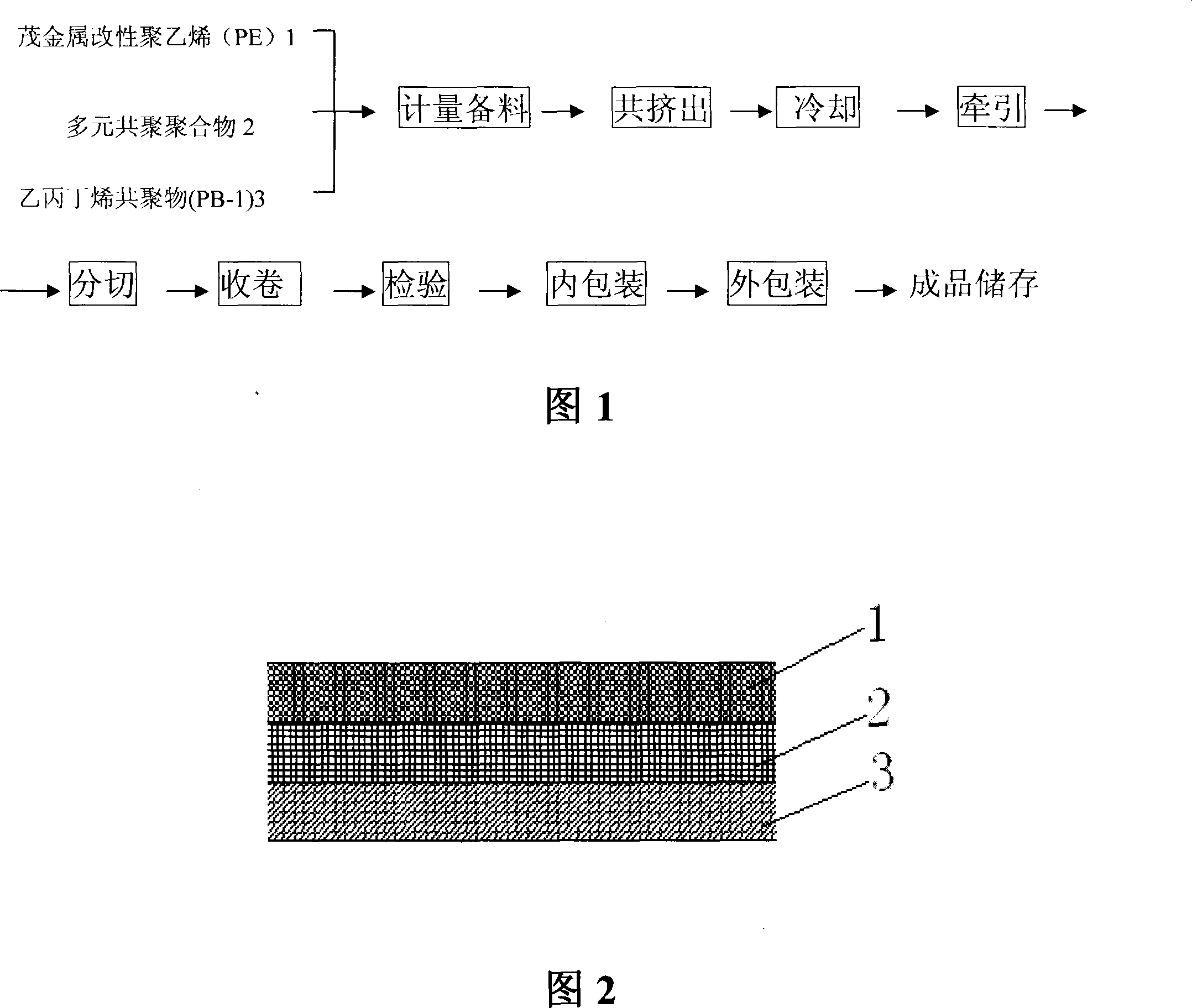

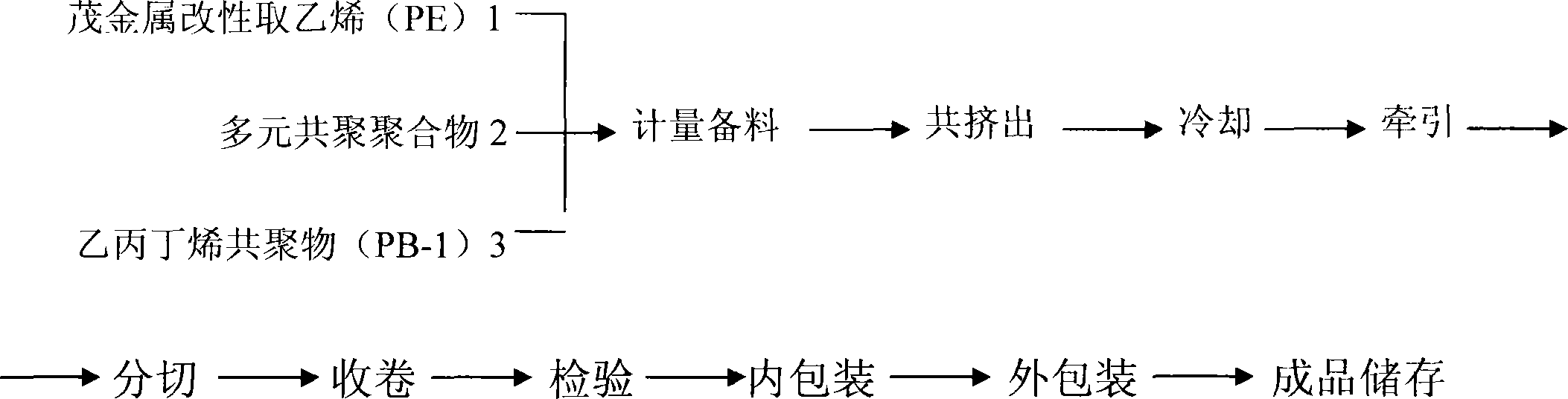

[0012] The present invention is a kind of high-barrier, high-temperature resistant and easy-to-tear film, which is composed of three layers of non-polar polymer materials, and the outer layer is modified polypropylene (PP) 1, which is high strength, high transparency Heat-sealing layer with high temperature resistance; the middle layer is multi-component copolymerized polyolefin (PE) 2, which is a strengthening layer for toughening function, adhesive function and heat-sealing strength; the inner layer is ethylene-propylene-butylene copolymer (PB-1) 3, which is It is an easy-peeling layer with high temperature resistance and stable chemical properties. When packaging foods such as convenience food, children's food, jelly, and soft cans, the inner layer of the present invention, that is, the three layers of ethylene-propylene-butylene copolymer (PB-1), is in contact with the packaged food and will not pollute the food. It adopts the world's most advanced modified polyolefin poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com