Patents

Literature

40results about How to "Good biological inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gel-based pH sensor preparation method thereof

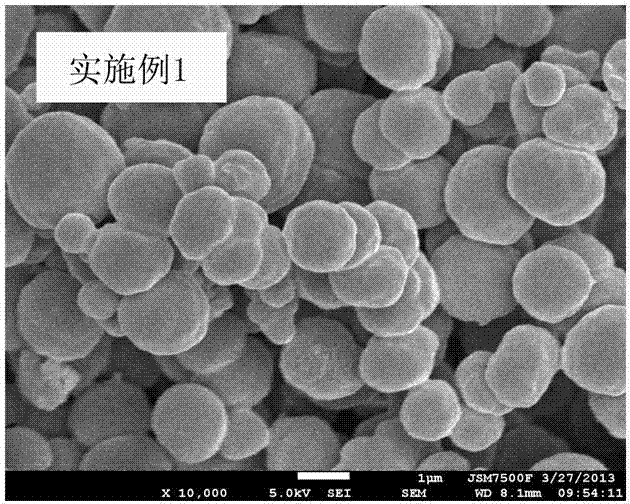

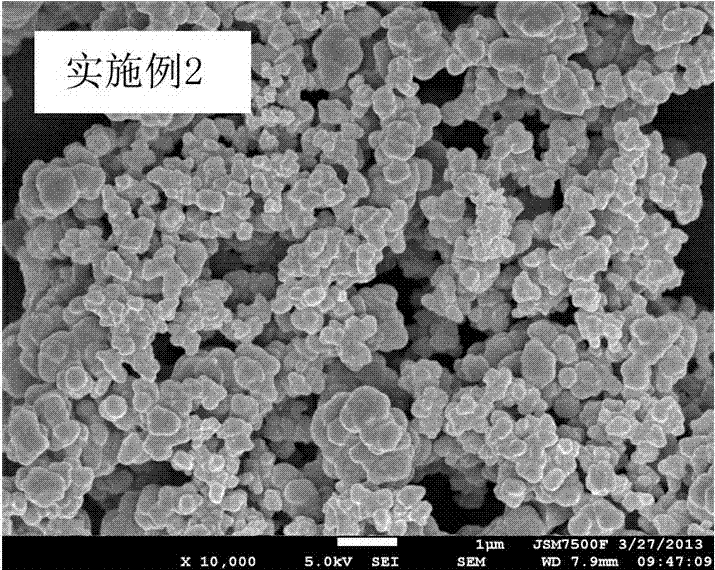

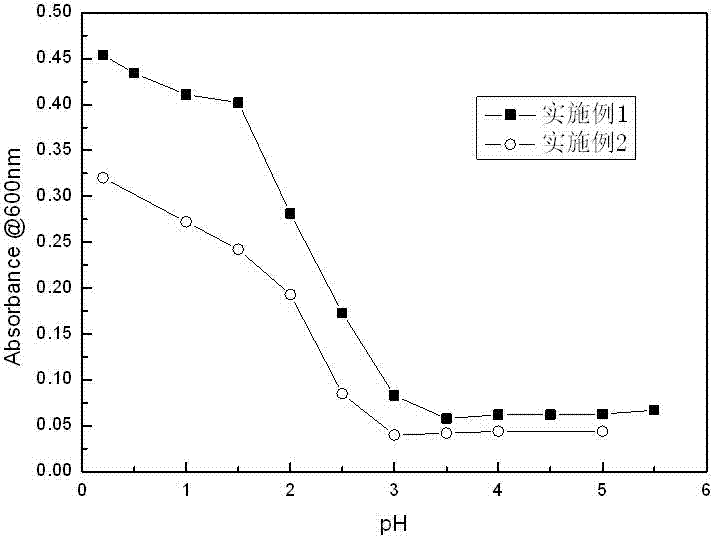

ActiveCN103543150AHigh mechanical strengthGood biological inertiaMaterial analysis by observing effect on chemical indicatorCongo redPolyvinyl alcohol

The invention provides a gel-based pH sensor and a preparation method thereof, belonging to the technical field of intelligent high molecules and sensors. The pH sensor is a composite material which takes polyvinyl alcohol gel as a matrix, and immobilizes and buries poly(acrylamide / methylacrylic acid) gel microspheres and immobilizes Congo red. The preparation method comprises the following steps: preparing a poly(acrylamide / methylacrylic acid) gel microsphere suspension; adding the microsphere suspension to polyvinyl alcohol aqueous liquor to crosslink and gelatinize; soaking a gel film in the Congo red for soaking, alkali treatment and washing to obtain a product. The gel-based pH sensor provided by the invention has the characteristics of absorbancy response and color response, so that visual simple measurement and precise measurement of pH value can be realized, and the using agility and application field of the pH gel sensor can be remarkably improved.

Owner:ZHENGZHOU UNIV

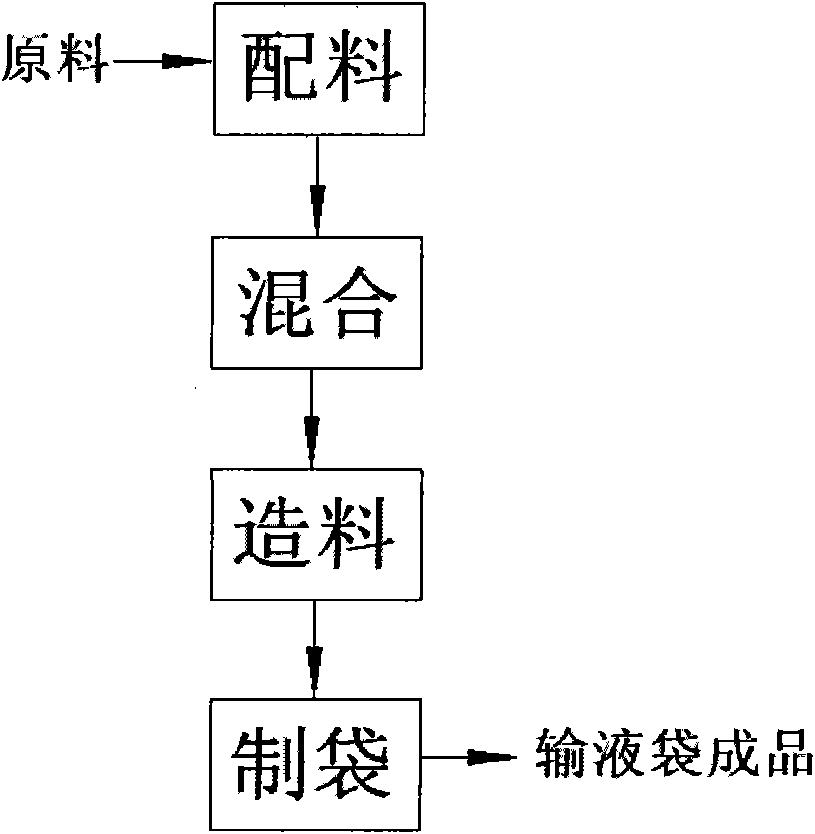

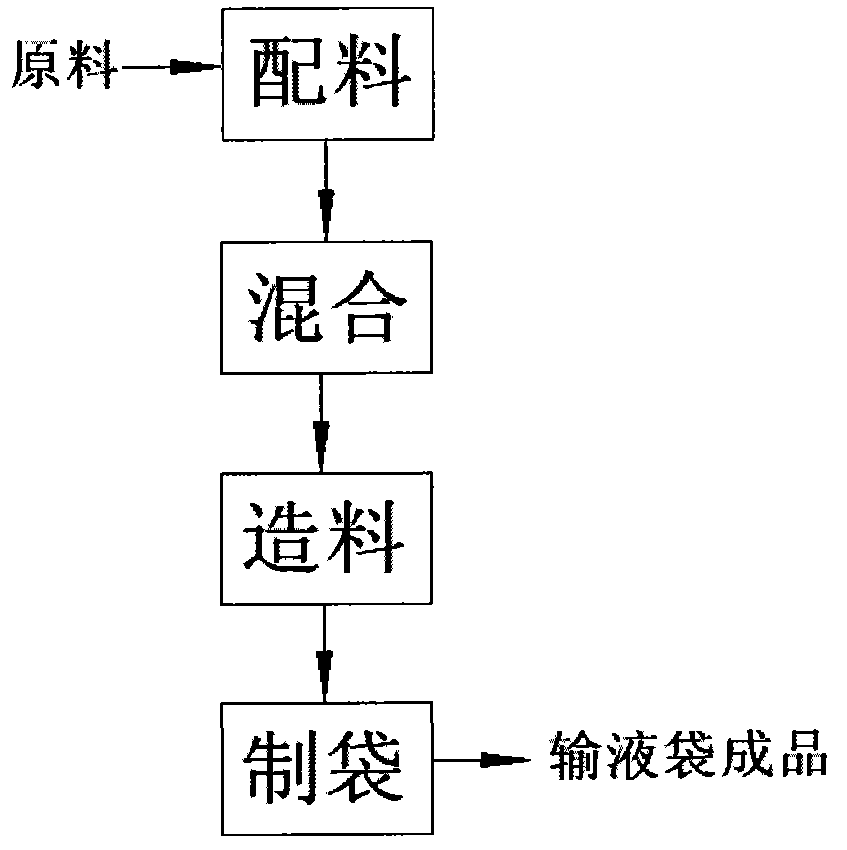

Manufacturing process and production equipment for medical infusion bags

InactiveCN101845173AImprove air tightnessImprove barrier propertiesPharmaceutical containersMedical packagingForeign matterPolypropylene

The invention discloses a medical infusion bag. The infusion bag is manufactured by using polypropylene and polyethylene and styrene-ethylene / butylene-styrene block copolymer. The infusion bag manufactured by adopting the technical scheme has the advantages that: the air-tightness and the steam resistance are excellent, the chemical stability is high, and the infusion bag is suitable to be used for manufacturing liquid medicinal products requiring high-temperature disinfection and sterilization; the transparence is high, and the detection of foreign materials when the infusion bag is produced and used is ensured; the softness is high, the falling resistance is high, the heat-sealing property is high, the high-temperature resistance is high, and the infusion bag can be sterilized at the temperature of 121 DEG C; because the infusion bag does not contain halogens, the infusion bag does not cause any environmental pollution when processed after use; and simultaneously, the barrier property is high, the chemical inertness and the biological inertness are high, the compatibility with medicaments is good, and the infusion bag can be used for packaging various kinds of common fluid, enteral nutrient fluid, parenteral nutrient fluid, dialyzate, flushing fluid, treating type large-capacity injection and the like.

Owner:ANHUI DOUBLE CRANE PHARMA

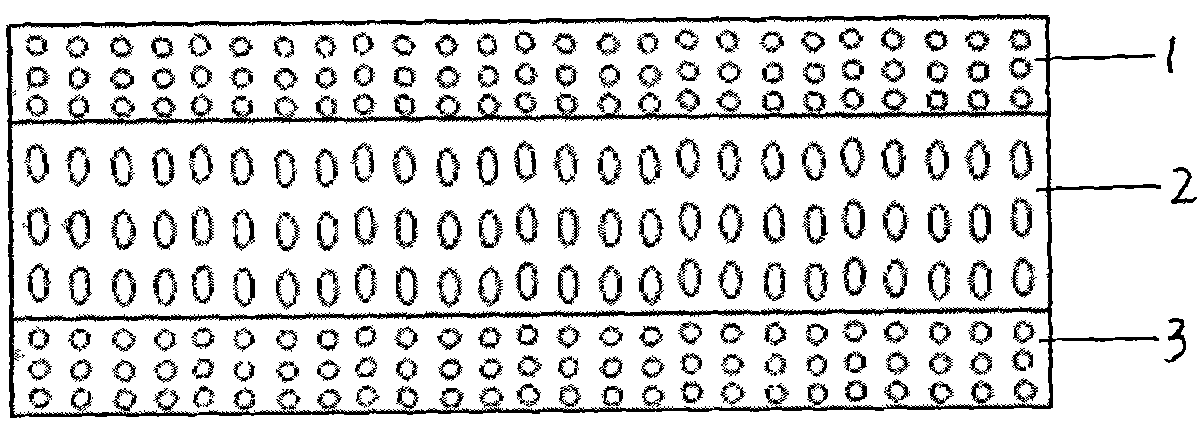

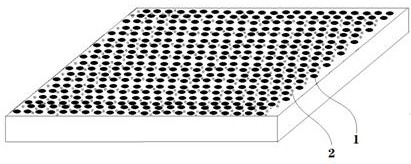

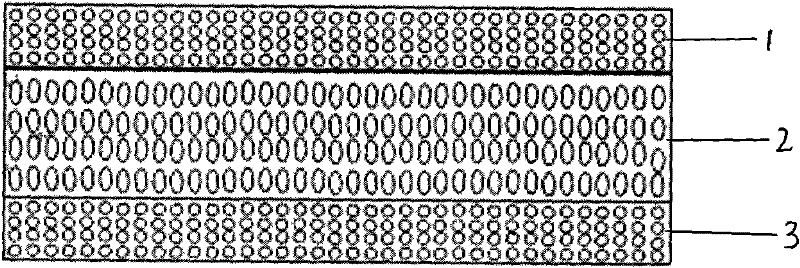

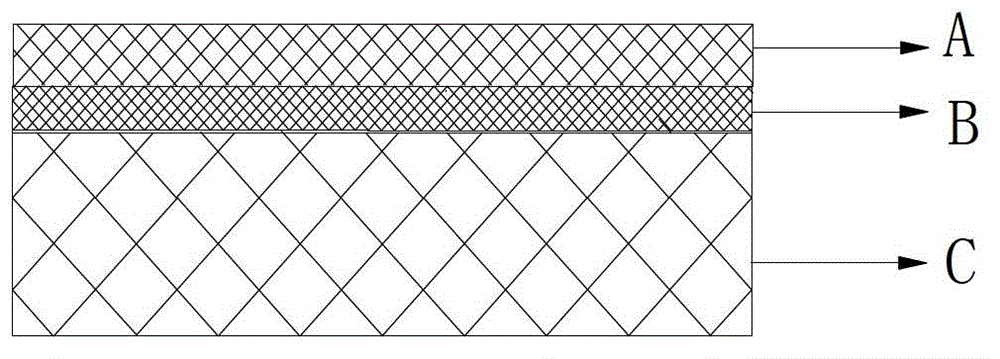

Calcium silicate high-filling polymer modified paper

InactiveCN102011347ALow lateral shrinkageWith whitenessSpecial paperPaper/cardboardLinear low-density polyethyleneCalcium silicate

The invention relates to calcium silicate high-filling polymer modified paper, which is compounded and formed by three layers of non-plant fiber calcium silicate substrates, wherein the first layer and the third layer are prepared from 2 to 6 percent of ethylene bis stearamide, 8 to 23 percent of high-density polyethylene, 3 to 9 percent of metallocene polyethylene, 0 to 1 percent of low-molecular polyethylene, 50 to 60 percent of activated calcium silicate, 10 to 25 percent of calcium silicate inorganic powder and 0 to 3 percent of addition agents, the first layer and the third layer accounts for 25 percent of the weight of the paper, the second layer is prepared from 50 to 60 percent of activated calcium silicate powder, 10 to 25 percent of calcium silicate, 2 to 9 percent of styrene-butadiene block copolymer, 7 to 21 percent of high-intensity polyethylene materials, 4 to 8 percent of linear low-intensity polyethylene and 0 to 3 percent of addition agents, and the second layer accounts for 50 percent of the weight of the paper. The modified paper has the same appearance, whiteness, sizing degree, opacity, strength, toughness and rigidity as plant fiber paper and has simple production processes, no bacteria and poison; and because the product is used for packing paper and can replace the traditional plastic packing paper, a great amount of petroleum can be saved.

Owner:宋旭

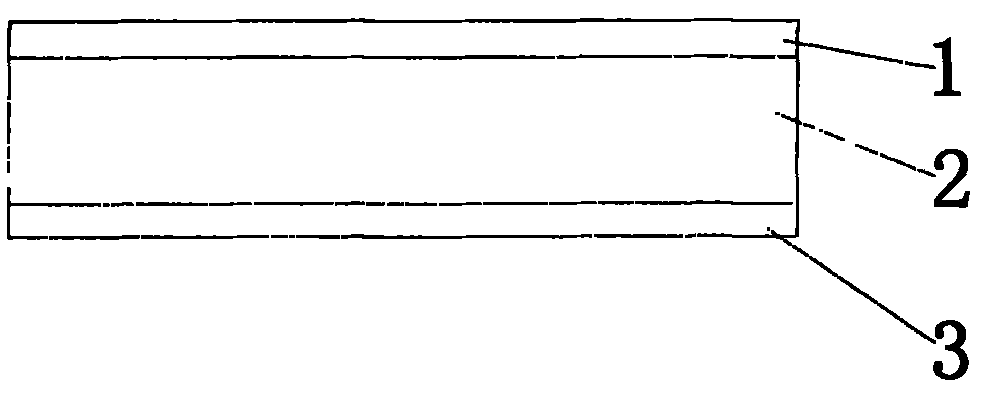

High-barrier thermophilic digestion resistant easy-stripping membrane

InactiveCN101181948AGood heat sealingGood sealingFlexible coversWrappersHigh resistanceEnvironmental resistance

The invention provides a high resistance and high temperature braising and cooking tearable membrane. The invention is characterized in that the invention consists of three layers of macromolecule material with good compatibility and close molecule structure, with the external layer is modified polyalkenes, the middle layer is multi-copolymerized polypropylene and the internal layer is terpolymer (ethene-ethylene-propylene butene). The modified polypropylene is metallocene modified polypropylene. The modified polypropylene occupies the proportion of 20% to 25%, the multi-copolymerized polypropylene occupies 50% to 60%, and the ethene-ethylene-propylene butene copolymer occupies 20% to 25%. The invention has extremely good biological inertia innocuity and is suitable for food packages; the invention does not generate the deformation, has wide applicable range, ensures the storages of convenient foods, children food, jelly, soft can, etc. not to be mortified or deteriorated, and reaches the requirement of asepsis (F0 is more than 8); the invention does not generate poisonous matters in the application and recovery process, has no pollution and belongs to environmental protective product.

Owner:郭瑞林

Heat-resistant insulating resin composition

The invention belongs to the technical field of high polymer materials, and particularly discloses a heat-resistant insulating resin composition. The heat-resistant insulating resin composition comprises the following raw materials in parts by weight: 60-80 parts of polypropylene resin, 22-35 parts of polyacrylate rubber, 15-26 parts of polyurethane rubber, 7-15 parts of polyisobutene grafted maleic anhydride, 15-30 parts of plasticizing agent, 5-10 parts of fire retardant, 5-10 parts of antioxidant, 3-6 parts of anti-aging agent, 4-8 parts of crosslinking agent and 1-2 parts of assistant crosslinking agent. The heat-resistant insulating resin composition disclosed by the invention has excellent mechanical property, flame retardant property and high temperature resistance.

Owner:HUANGHE S & T COLLEGE

Composite artificial cerebral dura mater and preparation method thereof

InactiveCN107537067ASimple processPromote migrationFilament/thread formingNon-woven fabricsFiberBiocompatibility Testing

The invention provides a composite artificial cerebral dura mater and a preparation method thereof. The composite artificial cerebral dura mater is made of polyvinylidene fluoride (PVDF) as a main body support material and a degradable polymer as an adjusting material of an orientation fiber through electrostatic spinning. The composite artificial cerebral dura mater provided by the invention is of a structure similar to an extracellular scaffold, is beneficial to cell migration, proliferation and differentiation; the main body support material PVDF in the composite material is good in proliferation and is beneficial to cell growth around a wound, a film is small in aperture, cerebrospinal fluid leakage or infection caused by bacteria is prevented, meanwhile good mechanical properties andflexibility are achieved, the composite material is good in biocompatibility, can be degraded in vivo, simple in preparation method, low in material cost and beneficial to industrial production, and degradation products are free of biotoxicity.

Owner:SHENZHEN UNIV

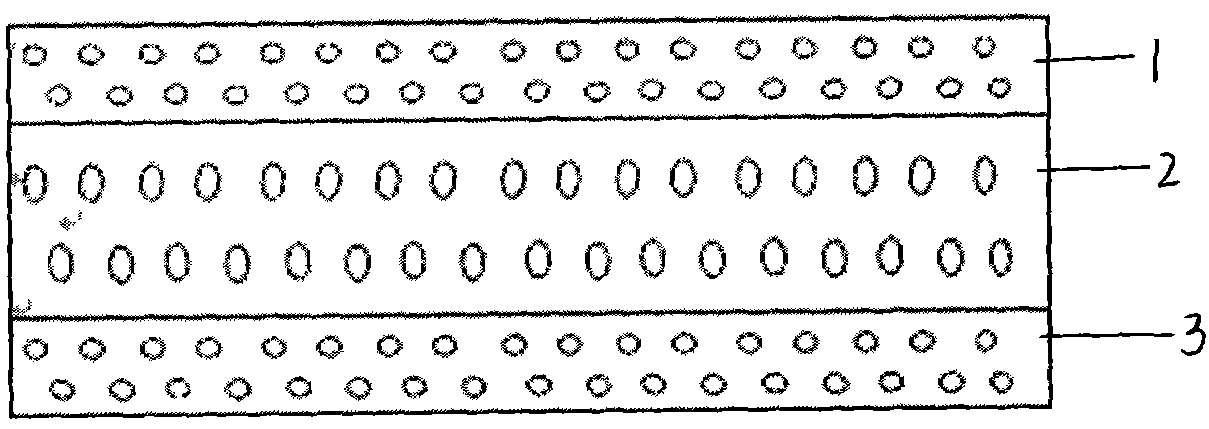

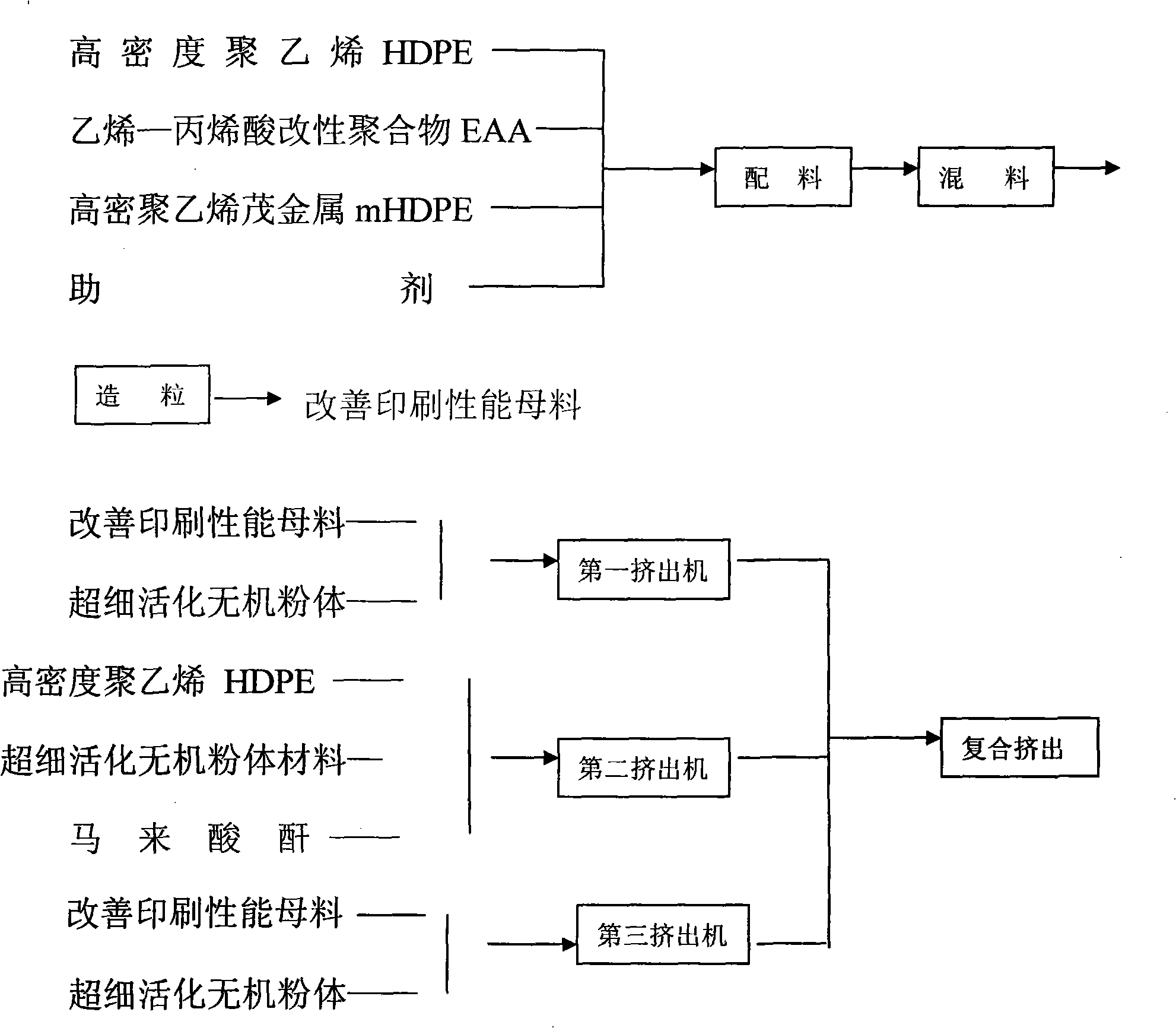

Modified polyolefins paper without plant fibre

InactiveCN101462387BOpaqueChemically resistantSynthetic resin layered productsHandwritingOrganic chloride compound

The invention discloses modified polyolefin paper without plant fiber. The modified polyolefin paper is formed by a first matrix layer without the plant fiber, a second matrix layer without the plant fiber and a third matrix layer without the plant fiber which are compounded into a whole, wherein the first matrix layer and the third matrix layer are respectively prepared by 20 to 30 percent of ethylene-acrylic acid modified copolymer EAA, 45 to 60 percent of metallocene high-density polyethylene mHDPE, and 20 to 25 percent of activated ultrafine inorganic powder by using an aluminate F-2 type coupling agent, and the second matrix layer is prepared by 60 to 90 percent of activated ultrafine inorganic powder, 2 to 5 percent of maleic anhydride and 8 to 35 percent of high-density polyethylene. The modified polyolefin paper has the advantages of good ink receptivity and softness. Therefore, the modified polyolefin paper can not only be used as industrial paper, packing paper and household paper, but also be used as cultural paper, and enlarges the use range. The modified polyolefin paper has higher foldability and rigidity, has the longitudinal and transverse tearing strength which are superior to those of plant fiber paper, has good surface flattening, good handwriting, and clear printing performance, saves printing ink, has simple production technology, protects forest resources, saves energy sources and water, reduces the discharge of organic chlorides and harmful gas, has no waste, and protects the environment.

Owner:宋旭

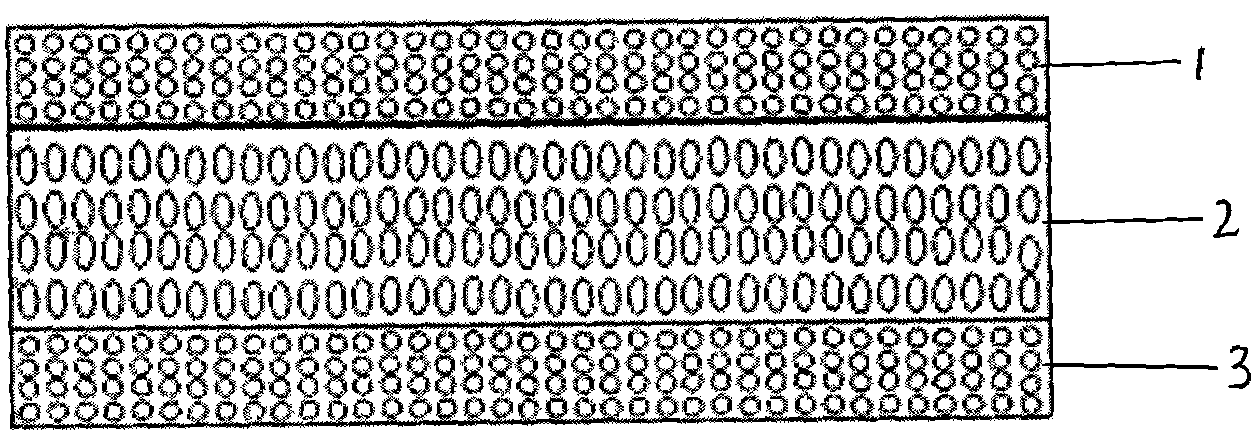

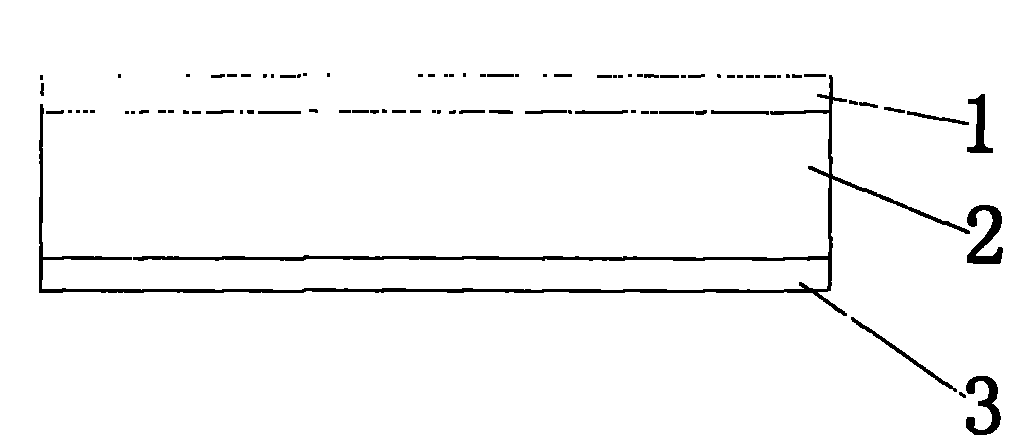

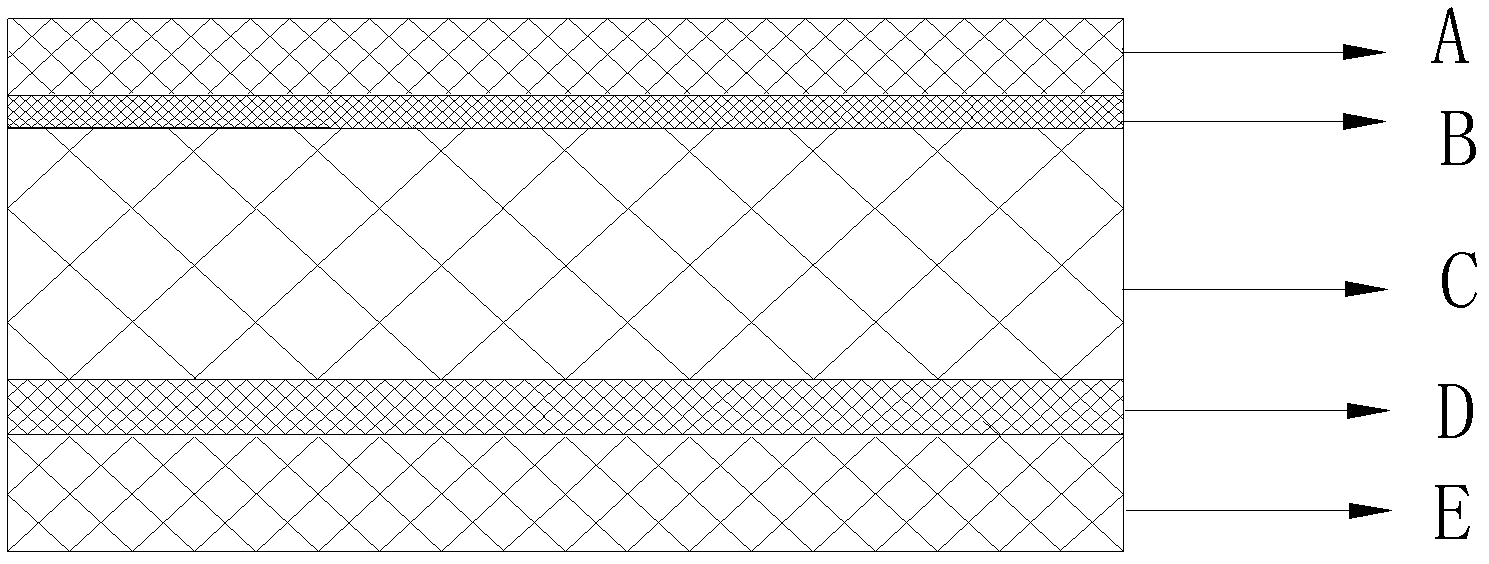

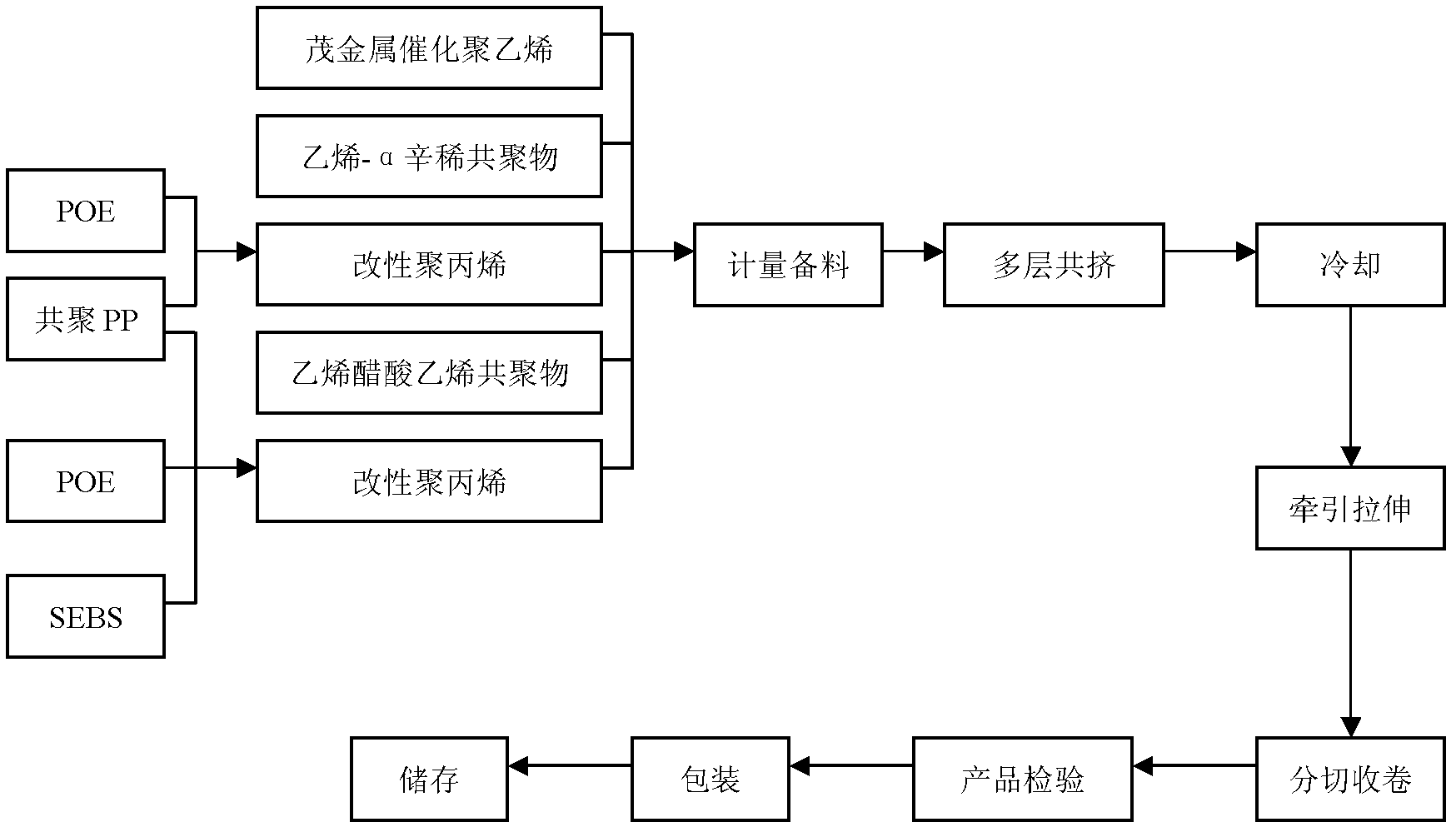

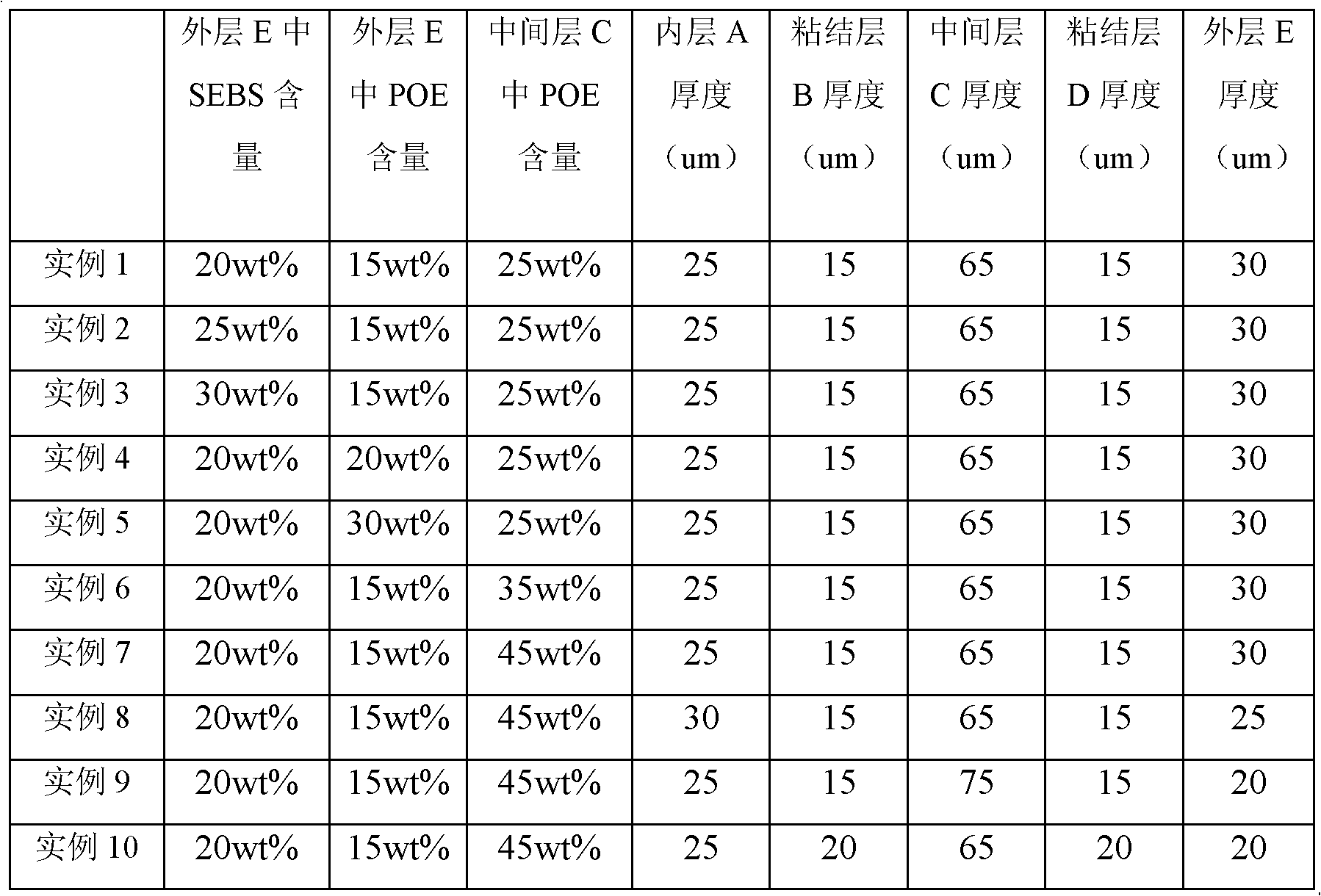

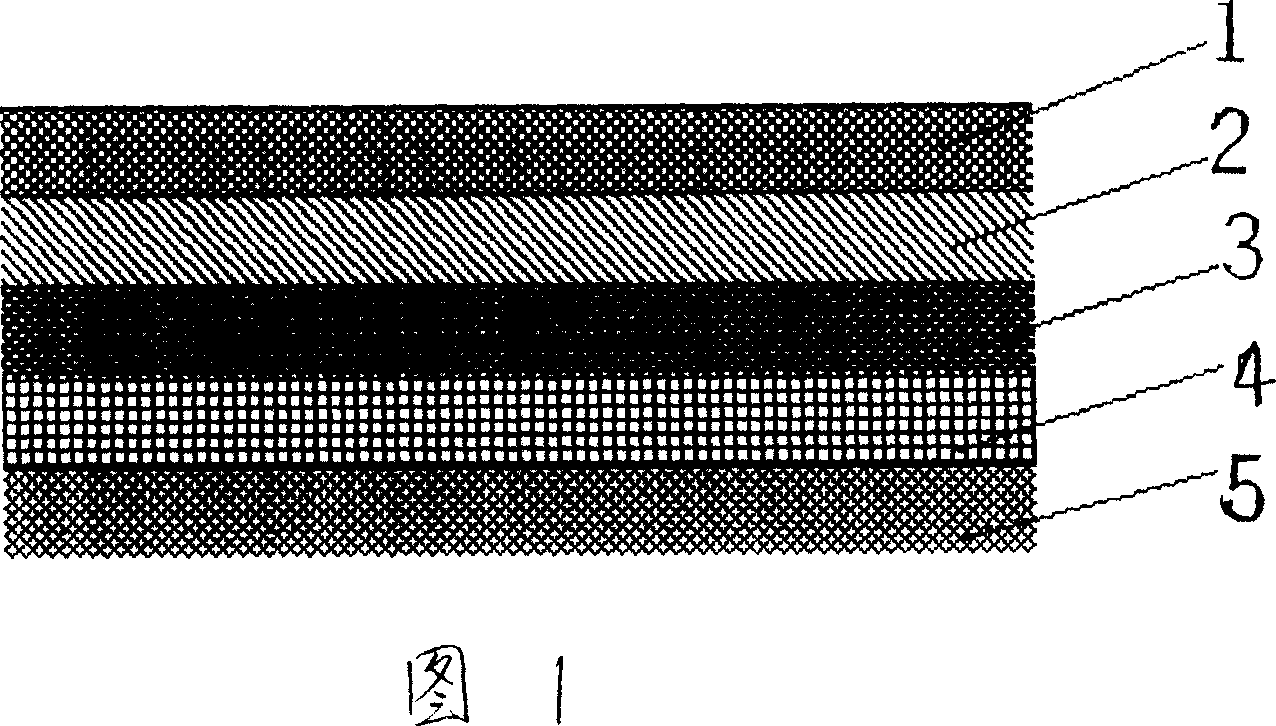

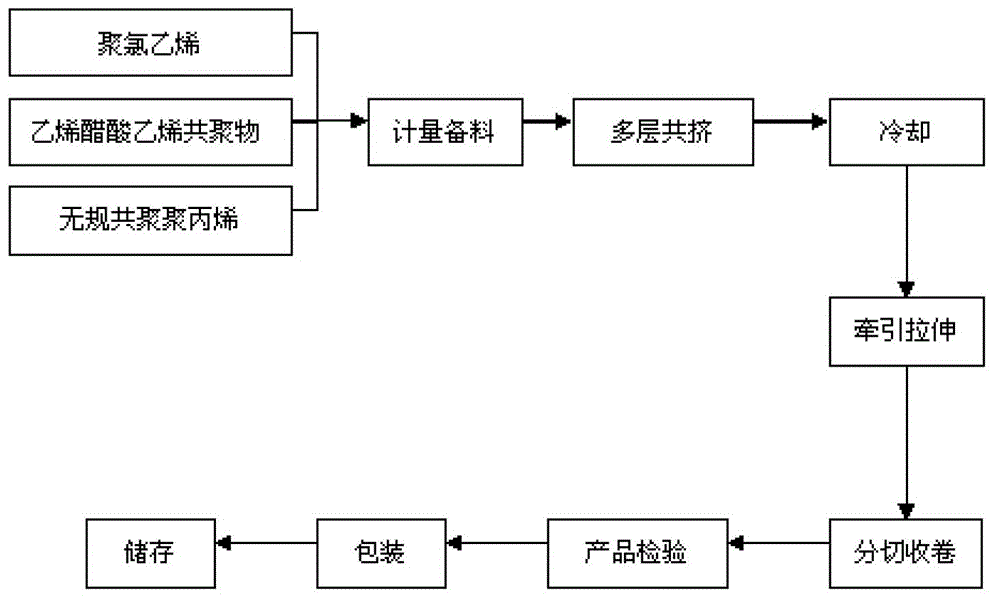

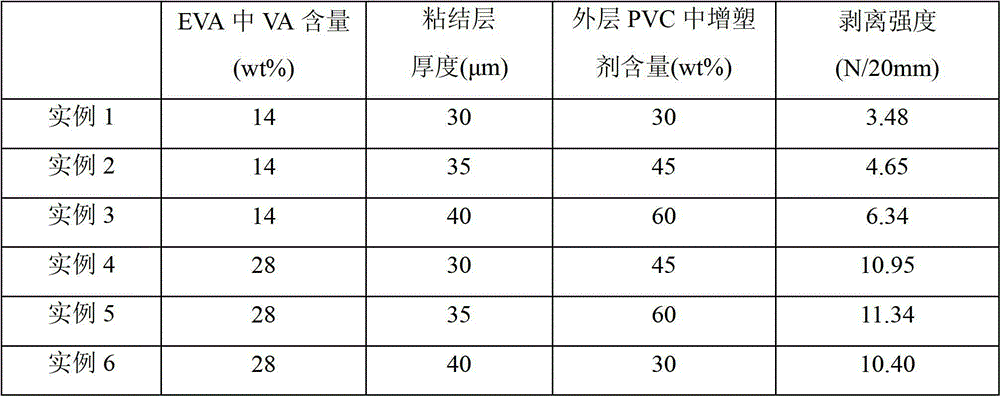

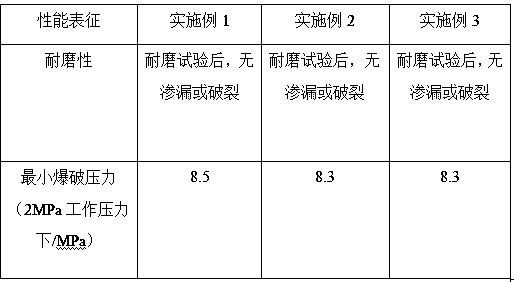

Novel multilayer co-extrusion medical transfusion film and preparation method thereof

ActiveCN102602094AGood flexibilitySelf-shrinkingSynthetic resin layered productsWeather resistanceMedicine

The invention relates to a novel multilayer co-extrusion medical transfusion film and a preparation method of the novel co-extrusion medical transfusion film. The materials of the novel multilayer co-extrusion medical transfusion film are divided into five layers in composition, wherein the first layer is an internal layer A and the ingredient of the internal A is polypropylene catalyzed by metallocene; the second layer is a bonding layer B and the ingredient of the bonding layer B is an ethylene-vinyl acetate copolymer; the third layer is a core layer C and the ingredient of the core layer C is mixed resin composed by random copolymerization polypropylene and an ethylene-alpha-octylene copolymer; the fourth layer is a bonding layer D and the ingredient of the bonding layer D is an ethylene-alpha-octylene copolymer; and the fifth layer is a weather-resistant layer E and the ingredient of the weather-resistant layer E is mixed resin composed by a random copolymerization polypropylene material, a styrene-ethylene-bivinyl rubber-styrene copolymer, and an ethylene-alpha-octylene copolymer. A multilayer co-extrusion technology is adopted in the preparation. The multilayer co-extrusion medical transfusion film provided by the invention has the advantages of high transparency, good weather-resistance and flexibility, wear resistance and the like, and is particularly appropriate for use as a packaging material in the field of medicine.

Owner:CHANGZHOU UNIV

Polyurethane/ceramic composite biological filler for sewage treatment and preparation method

InactiveCN112225309AGood effectDeveloped specific surface areaCeramic materials productionCeramicwarePolymer scienceCeramic composite

The invention provides a polyurethane / ceramic composite biological filler for sewage treatment and a preparation method. The preparation method comprises the following steps: mixing an anionic chain extender, isocyanate and polyethylene glycol, adding a triethylene diamine liquid catalyst, and carrying out reaction to prepare a polyurethane prepolymer; adding a proper amount of acetone, performingcooling, adding triethylamine and lactide, and performing stirring to obtain waterborne polyurethane; pre-treating municipal sludge, mixing pre-treated municipal sludge with natural magnesium aluminum silicate and aluminum oxide, carrying out dry ball milling, and performing treating to obtain ceramic with abundant porous structures; and placing the porous ceramic in a mixed solution of sodium alginate and absolute ethyl alcohol to be mixed, and then adding waterborne polyurethane, wherein the biocompatibility of the material can be enhanced through the waterborne polyurethane and the sodiumalginate. Therefore, the polyurethane / ceramic composite material prepared by the method integrates the advantages of high mechanical strength, large specific surface area and high porosity of the porous ceramic, and has the advantages of good biocompatibility, easiness in biofilm formation, high strength, easiness in backwashing and the like when being used as a biological filler.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Calcium silicate high-filling polymer modified paper

InactiveCN102011347BLow lateral shrinkageWith whitenessSpecial paperPaper/cardboardLinear low-density polyethyleneCalcium silicate

Owner:宋旭

Targeted perfluorocarbon oxygen-carrying microspheres for magnetic thermotherapy and preparation method and application thereof

InactiveCN110496228AHighly hydrophobicReduced responsePowder deliveryHalogenated hydrocarbon active ingredientsSolubilityMicrosphere

The invention provides a targeted perfluorocarbon oxygen-carrying microsphere for magnetic hyperthermia and a preparation method and application thereof. The preparation method comprises emulsifying perfluorocarbon into an emulsion, the perfluorocarbon emulsion is soluble in water and carrying oxygen, oxygenating and disinfecting the perfluorocarbon emulsion, wrapping the emulsion and magnetic nanoparticles in chitosan to form microspheres, and linking surface of the microspheres with polyethylene glycol and folic acid to improve water solubility of the microspheres and achieve a targeting function. In the preparation method, perfluorocarbon is used as an oxygen-carrying material and wrapped in chitosan together with the magnetic nanoparticles, the surface of the obtained microspheres is modified with polyethylene glycol molecules to improve the water solubility and grafted with folic acid molecules to form microspheres with a core-shell structure. The microspheres can achieve a sustained release effect of oxygen, the shell material has good biocompatibility and targeting, and the magnetic nanoparticles can exert magnetic thermotherapy in a magnetic field, thereby the ability of the microspheres to kill tumors is improved. The microspheres can alleviate hypoxia in tumor site and improve an effect of external adjuvant therapy.

Owner:TONGJI UNIV

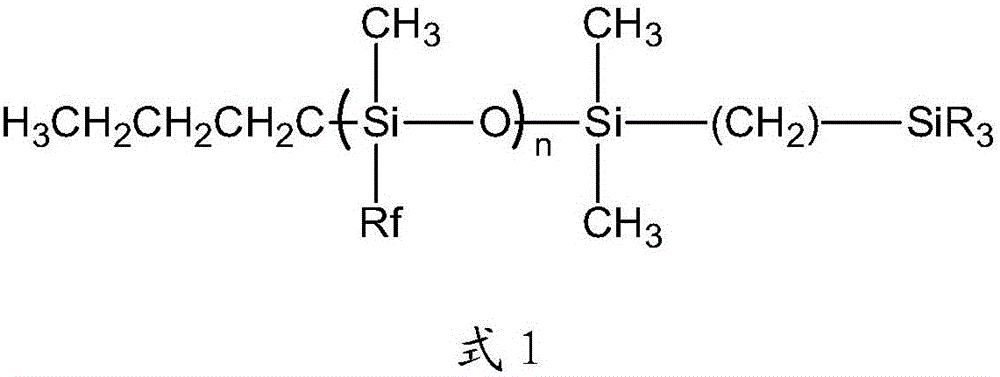

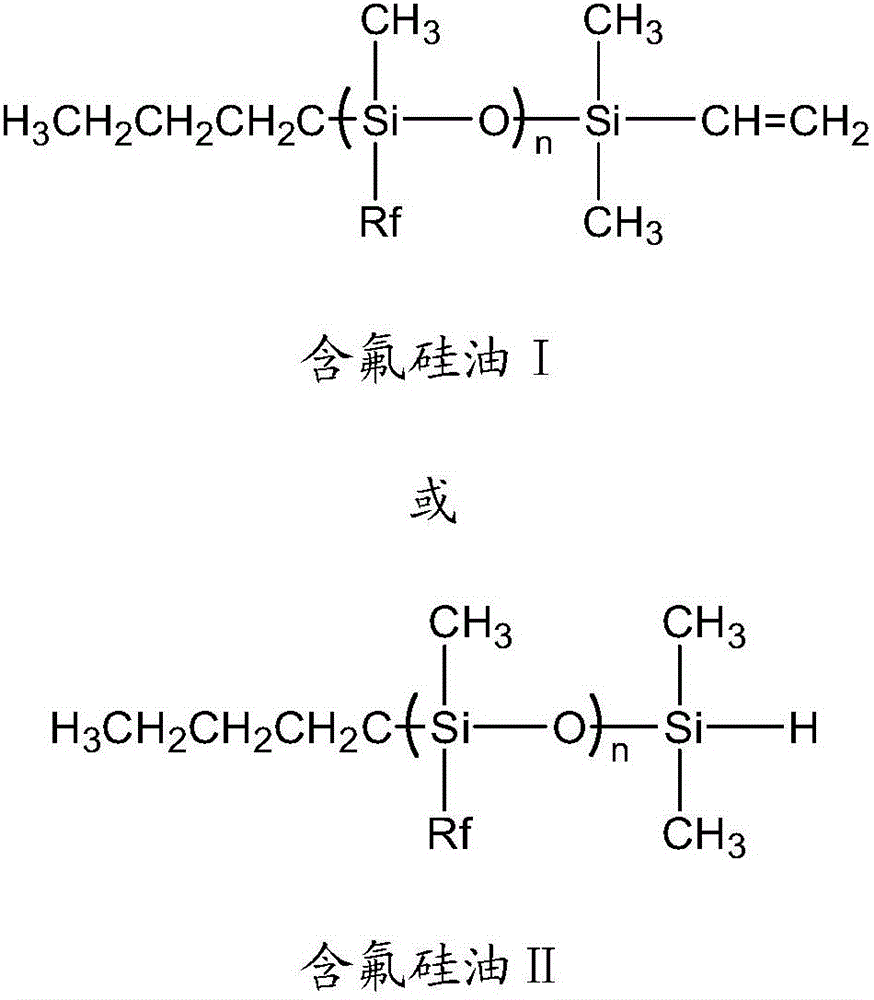

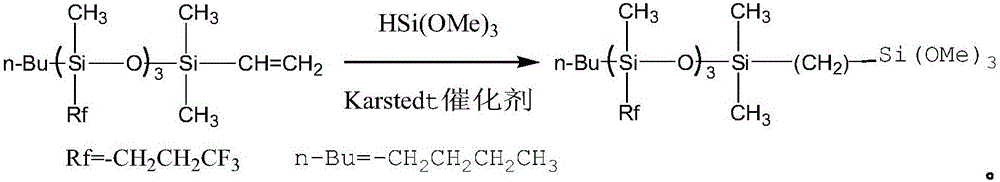

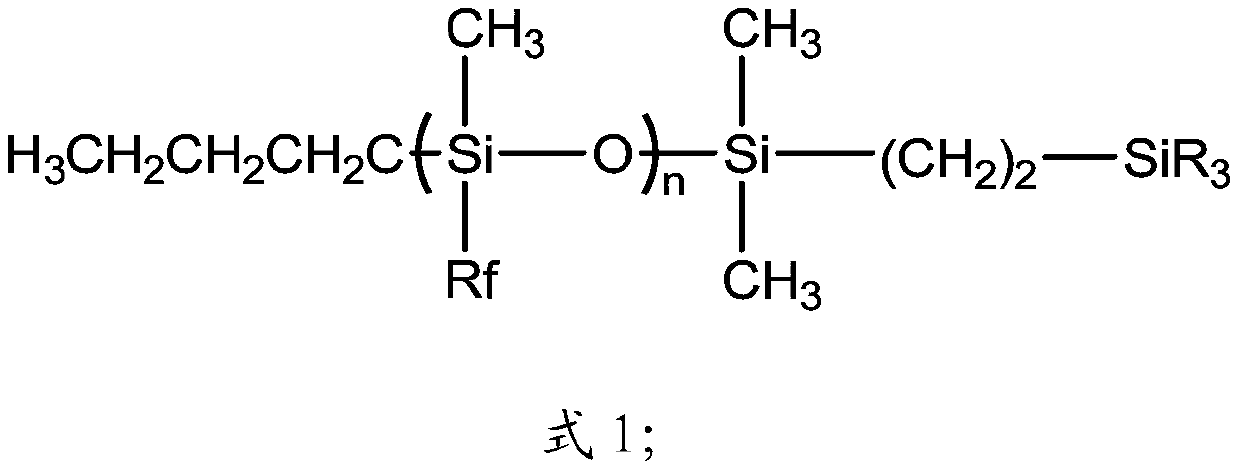

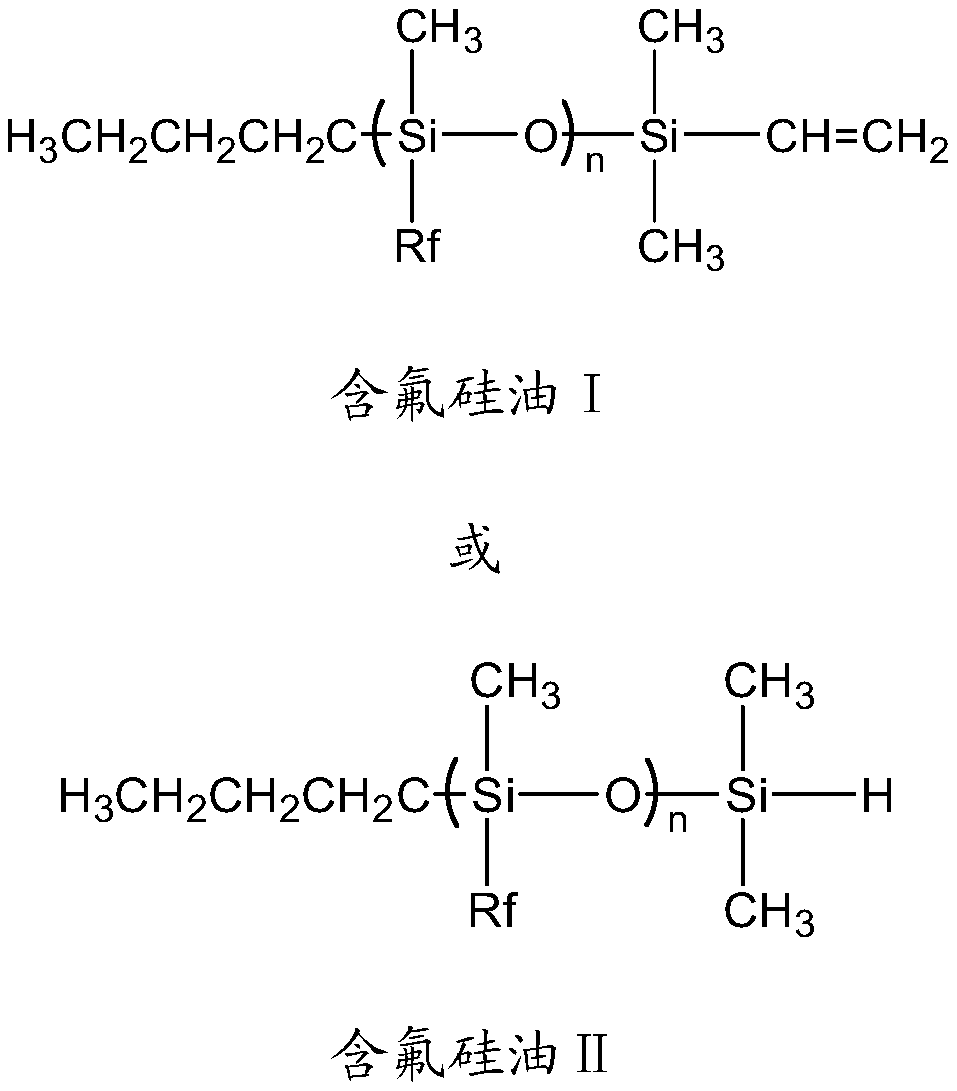

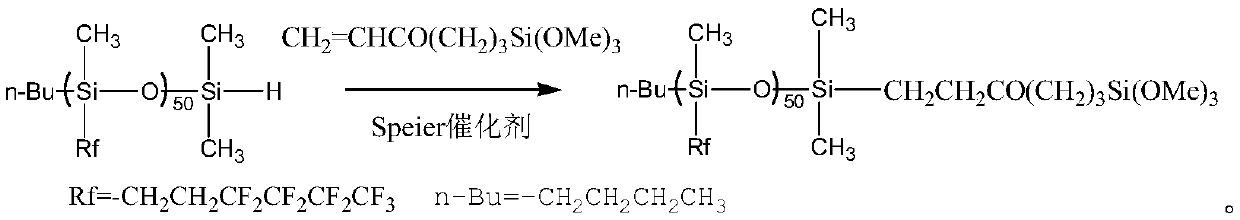

Fluorine-containing polysiloxane non-stick additive as well as preparation method and application thereof

ActiveCN106084233AGood biological inertiaImprove stabilityAntifouling/underwater paintsPaints with biocidesSolventSurface energy

The invention discloses a fluorine-containing polysiloxane non-stick additive as well as a preparation method and application thereof. The additive has a molecular formula 1 shown in the specification and is prepared through hydrosilylation reaction between fluorine-containing silicone oil with reactive groups and silane in the presence of a platinum catalyst. The non-stick additive and the preparation method have the beneficial effects that as fluorine-containing polysiloxane has low surface energy, solvent resistance, flexibility and high and low temperature resistance, the coupling agent can carry out key joint with most materials, endow base materials with good hydrophobicity, lipophobicity and pollution resistance and achieve the effect of improving the non-stick property of coatings; and the preparation method is simple, is mild in preparation conditions, has good repeatability, is high in yield and has wide application prospects.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Aqueous environmentally-friendly nano-copolymer multifunctional defoamer and preparation method thereof

ActiveCN110327665AImprove performanceGood shear stabilityFoam dispersion/preventionHazardous substanceWater source

The embodiment of the invention provides an aqueous environmentally-friendly nano-copolymer multifunctional defoamer and a preparation method thereof. The raw materials of the defoamer comprise, by mass, 20-26% of a natural vegetable fatty alcohol, 10-15% of a higher fatty alcohol, 5-10% of an amide, 5-8% of a nano-hydrophobic agent, 0.5-1% of a fluorine monomer, 3-6% of a silane, 2-5% of an initiator, 1-2% of an active polymerization agent, 0.5-1% of a catalyst, 1-2% of a thickener, 1-2% of an antifreeze agent and 30-45% of deionized water. The defoamer provided by the embodiment of the invention is prepared by raw material selection and a copolymerization synthesis mode, a nano-material group is introduced to change the polymer structure, and harmful substances such as a conventional emulsifier, formaldehyde and silicone oil are not used, so the versatility, the weather resistance, the stain resistance, the high corrosion resistance and the auto-cleaning property are improved. The product can be decomposed by hydrolysis, photodegradation and biodegradation without causing cumulative effects, so the product is very safe to water sources and the environment.

Owner:安徽广成新材料科技有限公司

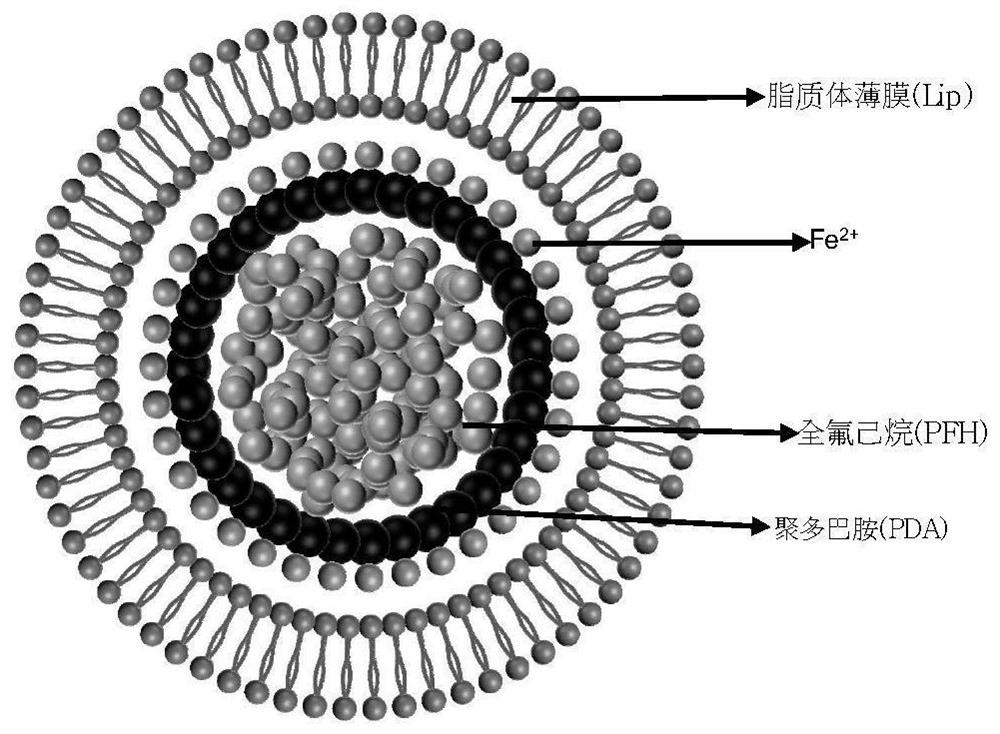

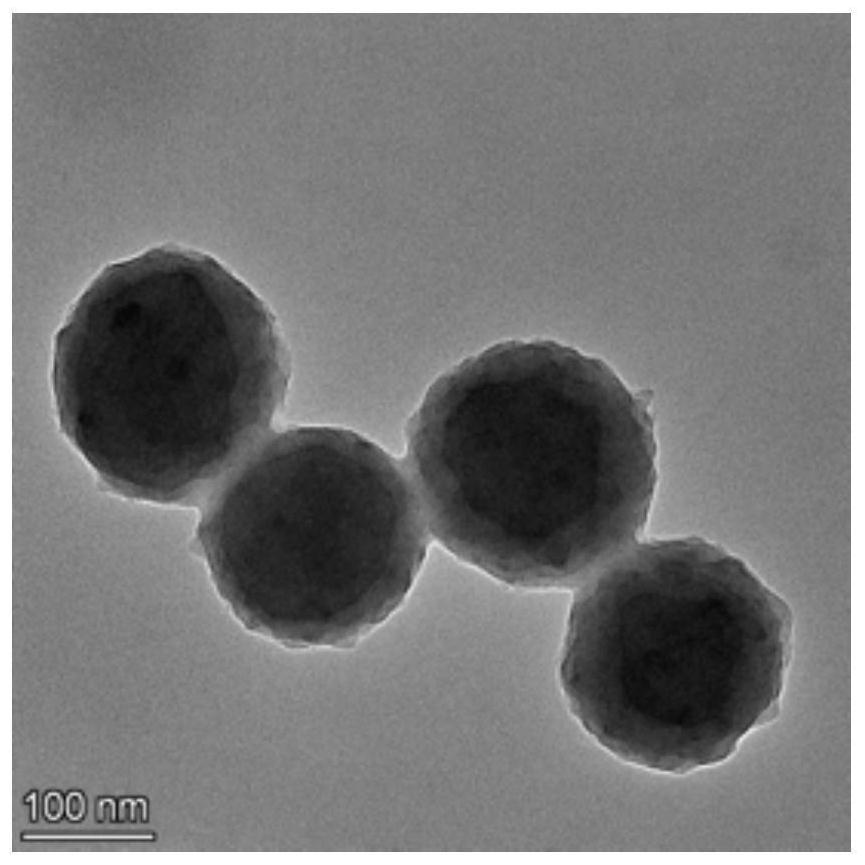

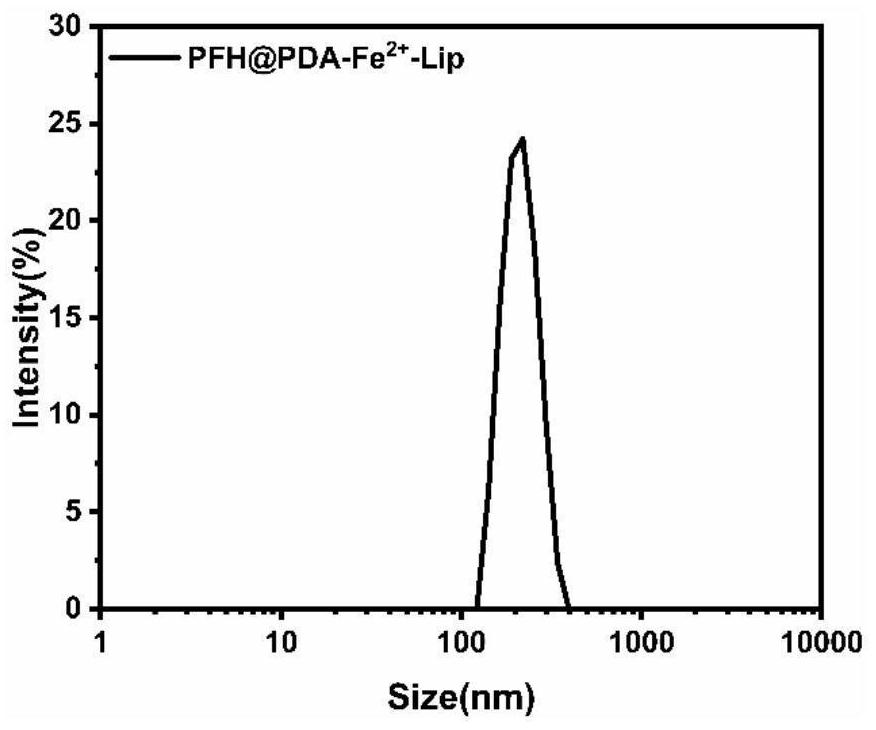

Polydopamine perfluorohexane nanoliposome and preparation method and application thereof

ActiveCN113350289AImprove hydrophobicityReduced responseHalogenated hydrocarbon active ingredientsHeavy metal active ingredientsEthanolamine synthesisPerfluorohexane

The invention provides polydopamine perfluorohexane nanoliposome and a preparation method and application thereof, and relates to nano materials and biomedical materials. The preparation method comprises the steps that 1), perfluorohexane is subjected to ultrasonic emulsification and dispersion in ultrapure water to form uniform nano emulsion; 2), the nano emulsion is blended with ammonium hydroxide and an ethanol solution, a dopamine hydrochloride solution is added, and stirring, centrifuging and cleaning are conducted; 3), ferrous lactate is added into a perfluorohexane-polydopamine nanoparticle solution, and stirring, centrifuging and cleaning are conducted; 4), soybean lecithin, cholesterol and distearoyl phosphatidyl ethanolamine are dissolved in dichloromethane, a liposome film is synthesized through a rotary evaporator, and a liposome film solution is subjected to ultrasonic dispersion; and 5), the liposome film solution is added into the nanoparticle solution in the step 3), ultrasonic dispersion and self-assembly are conducted, centrifuging and cleaning are conducted, and the polydopamine perfluorohexane nanoliposome is obtained. The defect that perfluorohexane is insoluble in water is overcome, the size of nanoparticles is small, the nanoparticles can be passively targeted to tumor cells through the high-permeability long-retention effect, tumor microenvironment hypoxia is improved, and iron death of the tumor cells is triggered.

Owner:XIAMEN UNIV

Composite film and preparation method and applications thereof

ActiveCN110841490AEasy to separateImprove heat resistanceMembranesSemi-permeable membranesPolymer scienceComposite film

The invention discloses a composite film, and a preparation method and applications thereof. The preparation method comprises the following steps: mixing vinyl-terminated fluorosilicone oil with hydrogen-containing silicone oil, chloroplatinic acid, a reaction solvent and a reaction inhibitor, stirring at 30-45 DEG C, and stopping stirring when the viscosity reaches 40-80 mPa*s so as to obtain a fluorine-modified silicone rubber solution; mixing cellulose acetate, dimethylacetamide, ethylenediamine propyl methyl dimethoxy silane and polyethylene glycol 400, stirring at 55-70 DEG C for 18-36 hours, coating the surface of non-woven fabric with an obtained mixture by blade coating, and carrying out phase inversion in water bath to obtain a base film; and uniformly coating the surface of the base film with the fluorine-modified silicone rubber solution, and crosslinking at 80-100 DEG C for 3-5 hours to obtain the composite film. The composite film is excellent in anti-pollution performance, and solvent resistance; the binding strength of the base film layer with an active film layer is high, the service life in yellow rice wine is long, separation of alcohol and aroma components in yellow rice wine can be realized effectively, clarified and transparent high alcohol concentration yellow rice wine can be prepared, and the turbidity of the yellow rice wine before penetrating through the composite film is high, and the composite film can be used for wine mixing or beverage mixing or further fermentation preparation of rice vinegar and other products.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

Perfluorocarbon oxygen-carrying microsphere and preparation method and application thereof

InactiveCN110433143AWide variety of sourcesGood biocompatibilityInorganic active ingredientsPharmaceutical non-active ingredientsOxygen deficiencyChemistry

The present invention provides a perfluorocarbon oxygen-carrying microsphere and a preparation method and an application thereof. The preparation method comprises the following steps: preparing perfluorocarbon into an emulsion, oxygenating and disinfecting the perfluorocarbon emulsion which is soluble in water and can carry oxygen, wrapping the emulsion in carboxymethyl chitosan to form microspheres, and connecting folic acid on surfaces of the microspheres to realize a targeting function. The perfluorocarbon oxygen-carrying microsphere is applied in treatments of tumors and alleviation of hypoxia. The perfluorocarbon is used as an oxygen-carrying material and wrapped in the carboxymethyl chitosan, and then the folic acid molecules are grafted to form the microspheres with a core-shell structure. The microsphere can realize a slow release effect of oxygen, besides, the shell layer material has good biocompatibility and targeting property, so that the microsphere can relieve an oxygen deficiency problem of a tumor part, realizes a function of slowly releasing oxygen at an oxygen deficiency part, and achieves a purpose of treating tumors. The perfluorocarbon oxygen-carrying microsphere is simple in the preparation method and convenient to operate, and the prepared oxygen-carrying microsphere can be stored for a long time.

Owner:TONGJI UNIV

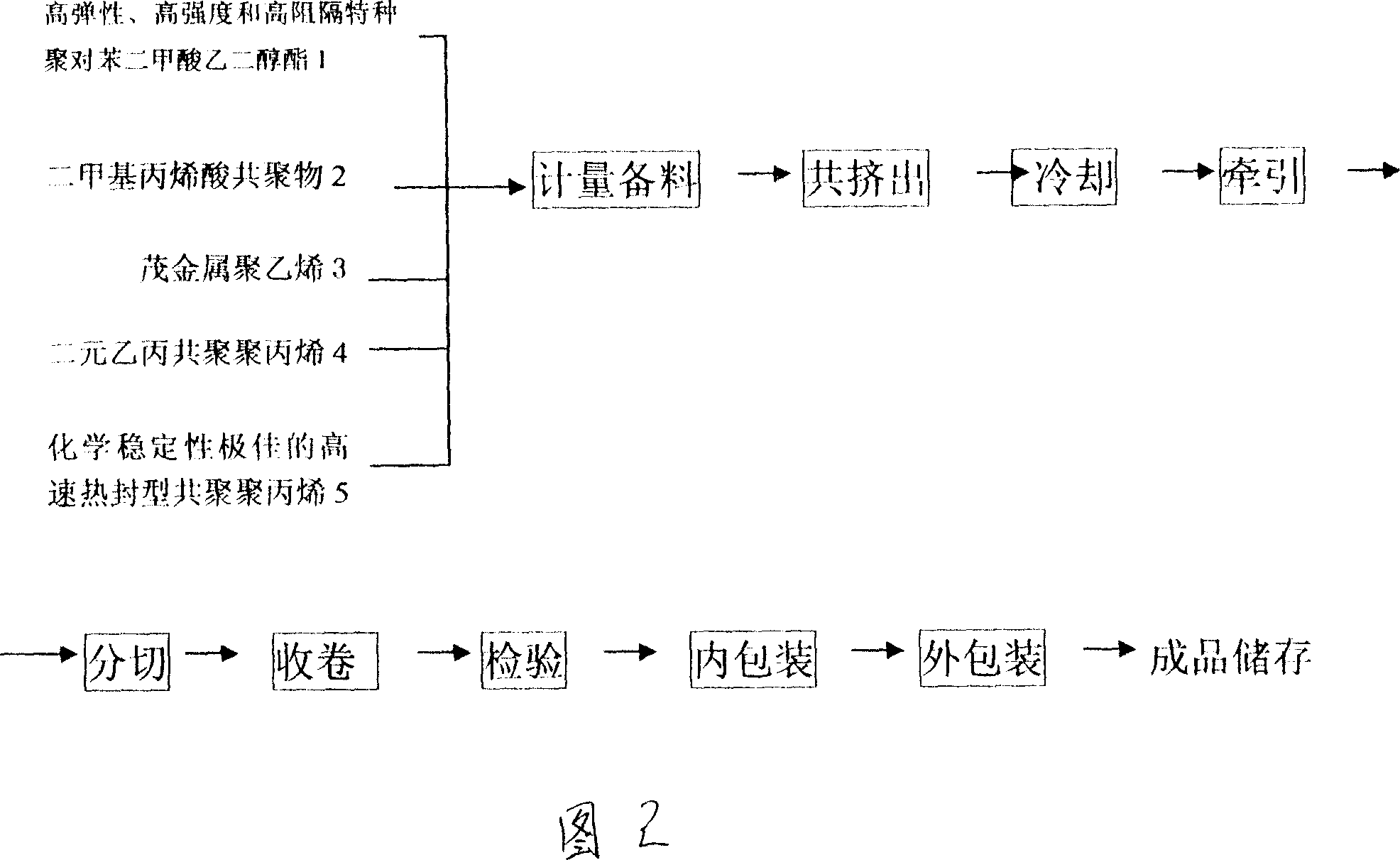

Multilayer co-squeeze film for transfusion

InactiveCN1927578AIncrease elasticityGood flexibilitySynthetic resin layered productsPolymer sciencePliability

A multilayer common squeezed film for transfusion is composite with five layers, the first layer is high elasticity, high intensity and high obstruct special polyethylene glycol terephthalate, the second layer is ethylenemethacrylic acid copolymer, the third layer is metallocene polyethylene, the forth layer is the dibasic ethylene ethylene-propylene copolymer and the fifth layer is quick-speed heat-sealing copolymerization polypropylene which has perfect chemical stability. This invention is a five layers common squeezed casing film for transfusion which is nonhazardous, high anti-dampness, high antioxidation, high-temperature, high-transparency, good-pliability, low-temperature and good-Intensity of heat seal.

Owner:李长青 +1

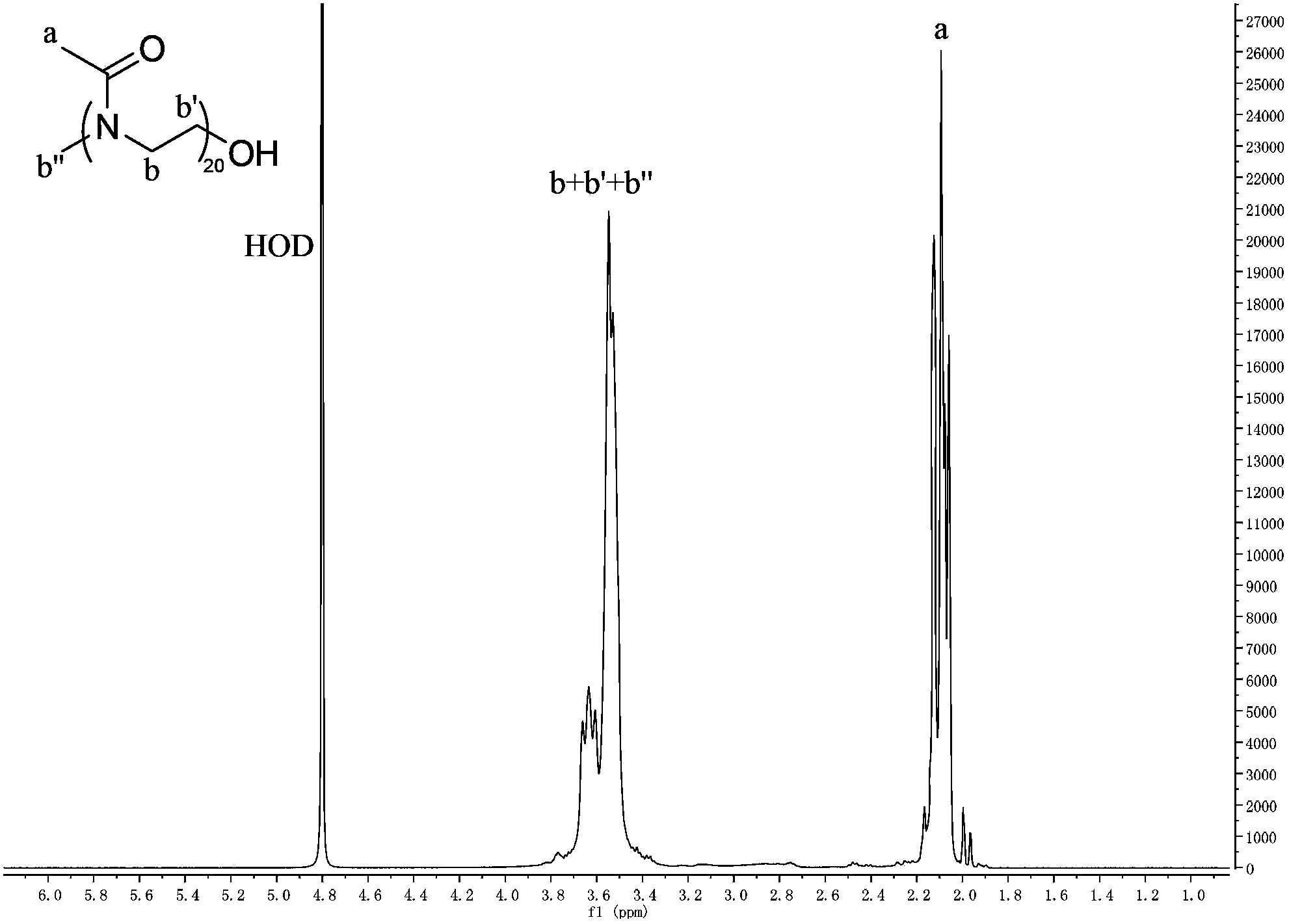

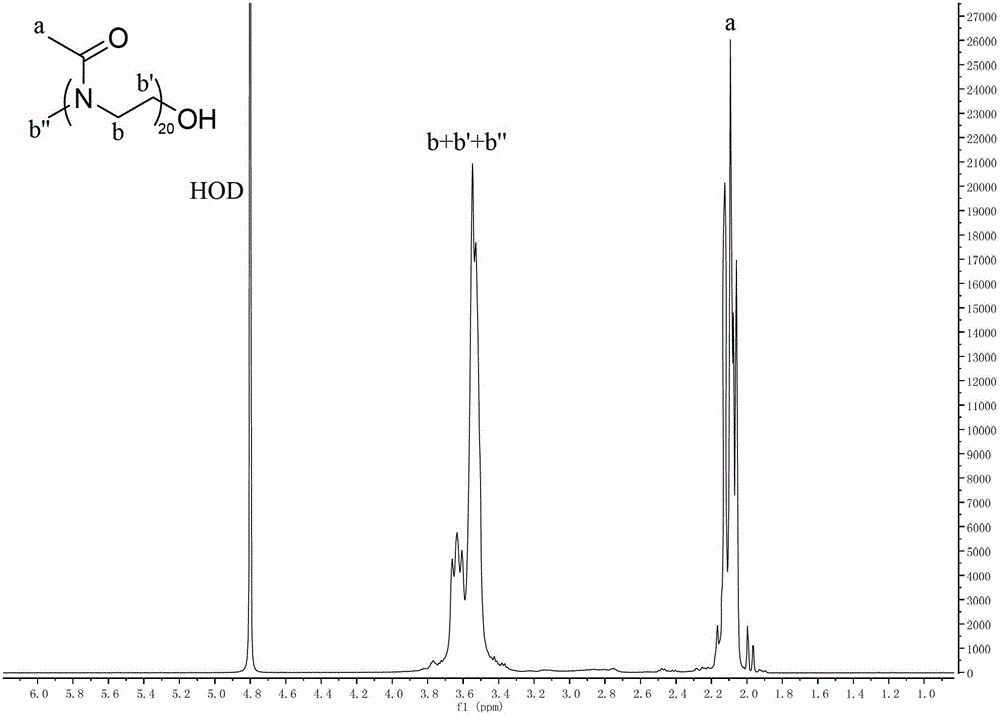

Polymer and its preparation method and application

The invention is applicable to the field of polymer materials, and provides a polymer, its preparation method and application. The polymer has the following structural formula. The polymer comprises poly oxazoline group and hydroxyl, carboxyl, amino, sulfydryl, azide group or trimethylsilyl group and triethoxysilyl group, the polymer has excellent biological inert, stability and easy synthesis property due to the poly oxazoline group, and due to the hydroxyl, carboxyl, amino, sulfydryl, azide group or trimethylsilyl group and triethoxysilyl group and other active functional groups, cross-linking reaction of the polymer and functional groups with other properties can be performed, so that the range of application of the polymer is greatly widened; according to the preparation method of the polymer, through the introduction of the poly oxazoline group and other active functional groups, the proposes that the polymer has the excellent biological inert, stability and easy synthesis property and the cross-linking reaction of the polymer and the functional groups with other properties can be performed can be realized.

Owner:张昊 +1

A kind of fluorine-containing polysiloxane non-stick additive and its preparation method and application

ActiveCN106084233BLower surface energyLow solvent resistanceAntifouling/underwater paintsPaints with biocidesSilanesCoupling

The invention discloses a fluorine-containing polysiloxane non-stick additive as well as a preparation method and application thereof. The additive has a molecular formula 1 shown in the specification and is prepared through hydrosilylation reaction between fluorine-containing silicone oil with reactive groups and silane in the presence of a platinum catalyst. The non-stick additive and the preparation method have the beneficial effects that as fluorine-containing polysiloxane has low surface energy, solvent resistance, flexibility and high and low temperature resistance, the coupling agent can carry out key joint with most materials, endow base materials with good hydrophobicity, lipophobicity and pollution resistance and achieve the effect of improving the non-stick property of coatings; and the preparation method is simple, is mild in preparation conditions, has good repeatability, is high in yield and has wide application prospects.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Resin composition with good mechanical properties

The invention discloses a resin composition with good mechanical properties, which is prepared from the following raw materials: polypropylene resin, acrylate rubber, polyurethane rubber, polyisobutylene grafted maleic acid dimer, plasticizer, antimony trioxide, antioxidant, anti-aging agent, cross-linking agent, co-crosslinking agent and silicone rubber. The composition has special surface performance, low water absorption, no breeding effect on various algae and molds, good mildew resistance, good thermal conductivity and good air permeability. The composite varies greatly in permeability todifferent gases and is stinkless and tasteless. The material has excellent antithrombotic and biological inertia. The composition is commonly used with polypropylene rubber, acrylate rubber and polyurethane rubber, so that the heat resistance and the flexibility of the insulating resin composition are further improved.

Owner:吴辉

Insulating resin composition

The invention discloses an insulating resin composition which is prepared from the following raw materials: polypropylene resin, acrylic rubber, polyurethane rubber, polyisobutylene grafted maleic anhydride, a plasticizer, antimonous oxide, an antioxidant, an anti-aging agent, a crosslinking agent, an assistant crosslinker and silicone rubber. The insulating resin composition disclosed by the invention has special surface property and low moisture absorption property, has no an effect of breeding various algae and molds, is excellent in mildew resistance, excellent in heat-conducting propertyand air permeability, and is great in air permeability difference from different gases, odor-free, tasteless and excellent in thrombosis resistance and bio-inert. When the composition is used with thepolypropylene resin, acrylic rubber and polyurethane rubber, the heat resistance and flexibility of the insulating resin composition are further improved.

Owner:吴辉

Resin composition with good flexibility

InactiveCN108559211ARegular structureImprove mechanical propertiesRubber insulatorsAntioxidantThrombus

The invention discloses a resin composition with good flexibility. The resin composition is prepared from the following raw materials: a polypropylene resin, polyacrylate rubber, polyurethane rubber,polyisobutene grafted maleic anhydride, a plasticizer, antimonous oxide, an antioxidant, an anti-aging agent, a crosslinking agent, an assistant crosslinker and silicon rubber. The resin composition has special surface properties, is low in water absorption, has no propagation function on various algae and mold, is good in mold resistance, heat conduction and air permeability, in addition has great air permeability differences for different gases, is non-odorous and tasteless, ha very good thrombus resistance and biological nonreactivity, and can be used together with the polypropylene resin,the polyacrylate rubber and the polyurethane rubber, and the thermal resistance and the flexibility of the insulating resin composition can be further improved.

Owner:吴辉

Heat-resistant insulating resin composition

The invention discloses a heat-resistant insulating resin composition which comprises the following raw materials: polypropylene resin, acrylic rubber, polyurethane rubber, polyisobutylene grafted maleic anhydride, a plasticizer, antimonous oxide, an antioxidant, an anti-aging agent, a cross-linking agent, an assistant crosslinker and silicone rubber. The heat-resistant insulating resin composition disclosed by the invention has special surface properties and low water-absorbing quality, has an effect of preventing breeding of various algae and molds, is good in mildew resistance and excellentin heat-conducting property and air permeability, has a great difference on air permeability of different gases, is odorless and tasteless, has excellent thrombosis resistance and bio-inert, and is in common use with polypropylene resin, acrylic rubber and polyurethane rubber. The heat resistance and flexibility of the insulating resin composition are further improved.

Owner:吴辉

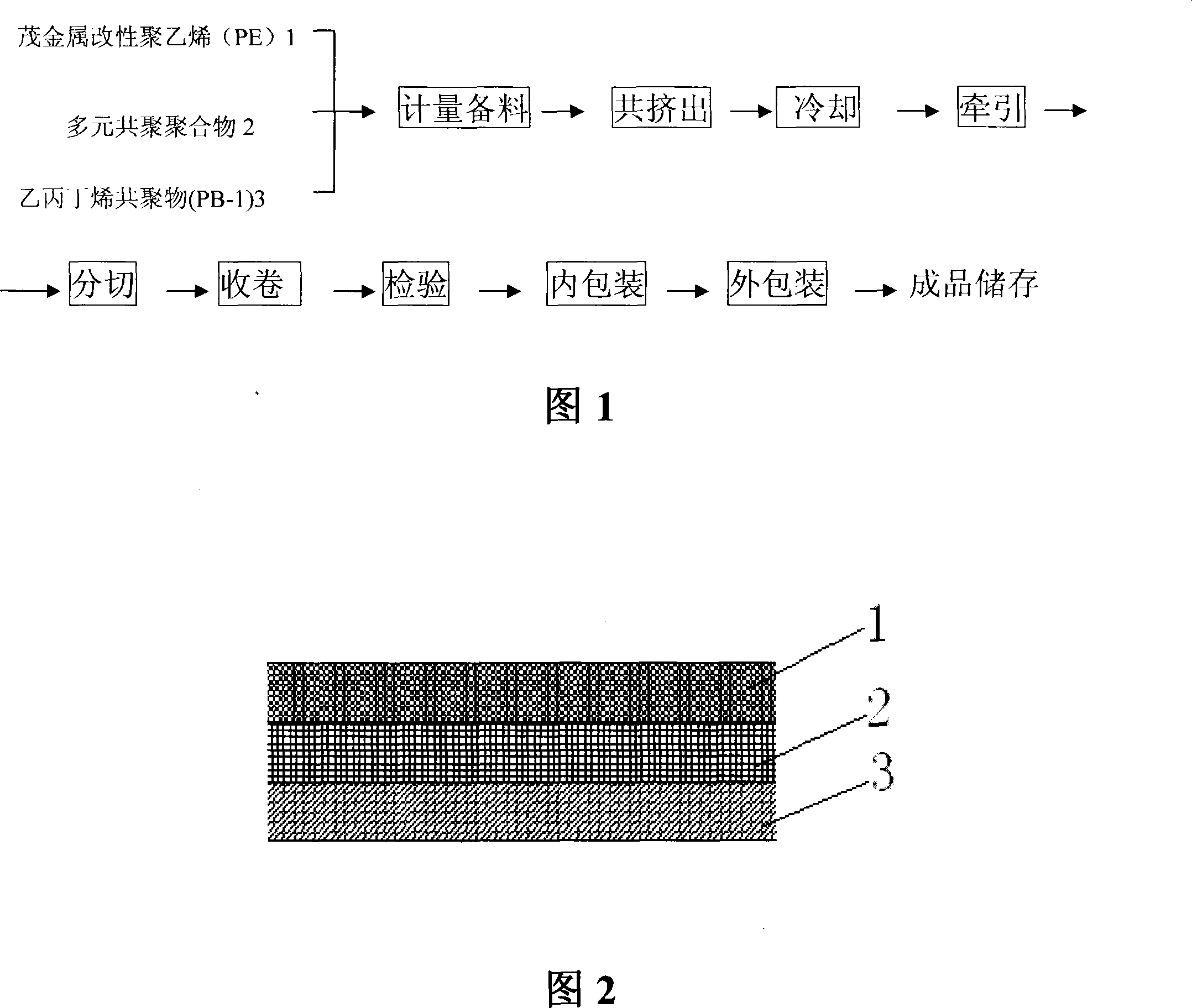

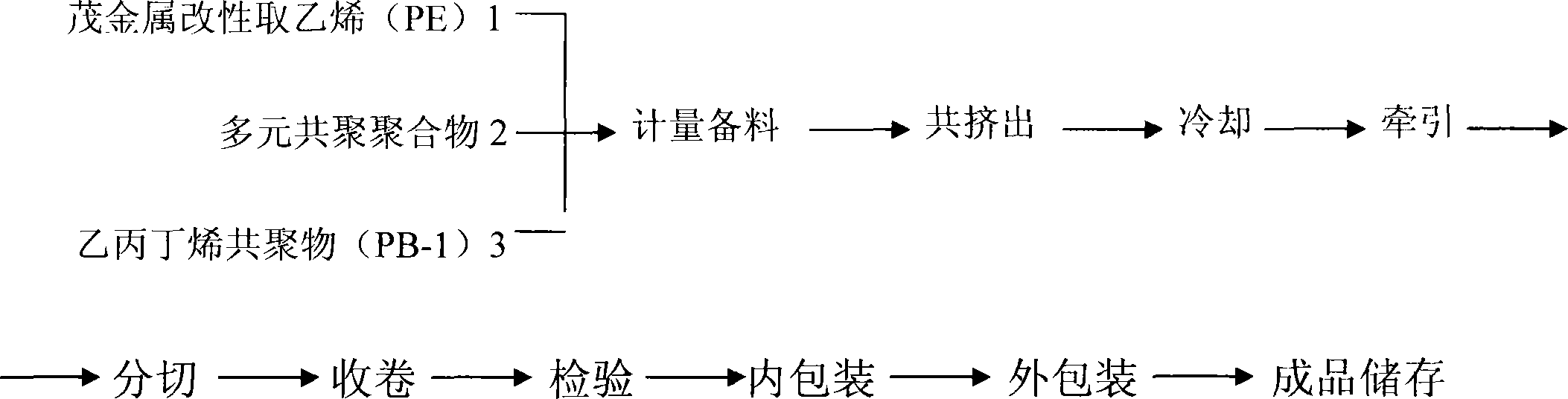

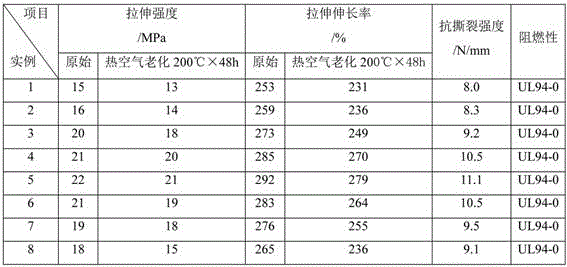

Three-layer coextrusion film for infusion and preparation method of three-layer coextrusion film

ActiveCN102794961BAvoid health hazardsGood flexibilitySynthetic resin layered productsPliabilityInstability

Owner:CHANGZHOU UNIV

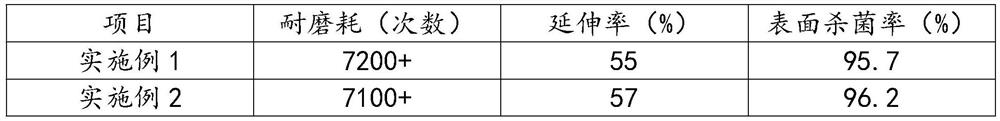

Method for preparing lining material of fire hose

InactiveCN110746778AImprove corrosion resistanceGood weather resistanceWeather resistanceHydrotalcite

The invention relates to a method for preparing a lining material of a fire hose and belongs to the technical field of fire fighting. The method comprises the following steps: by taking silicone rubber as a raw material of a lining material, doping the silicon rubber with cerium oxide and an aluminum alloy, and preparing a hydrotalcite-like thin film on the surface of the silicon rubber by using an in-situ growth method, so as to prepare a lining material of a fire hose with good oil resistance and corrosion resistance. The silicone rubber has excellent weather resistance, high and low temperature resistance, electrical insulation, radiation resistance and biological inertia; because of a special electron structure (an f electron layer is underfill) of rare earth cerium, a complex can be easily formed, the formed complex is capable of inhibiting swelling of rubber in a solvent by preventing chain segment movement of rubber molecules, and then the oil resistance of the rubber can be improved; and when the hydrotalcite-like thin film is in contact with a solution, original anions in layers have an exchange reaction with anions in the solution, corrosive ions in layers can be contained in layers, contact of a substrate with the corrosive ions can be inhibited, and thus the purpose of inhibiting corrosion can be achieved.

Owner:陈环英

Damping cloth with good wear resistance and preparation method thereof

PendingCN113047058AImprove wear resistanceReduce scratchesTextiles and paperPolymer scienceHigh wear resistance

The invention discloses damping cloth with good wear resistance and a preparation method thereof. The damping cloth comprises base cloth and a wear-resistant coating; the preparation method comprises the following steps: 1, uncoiling the base cloth, immersing the base cloth into a soaking tank containing an anionic surfactant and water in a mass ratio of 1:100 through a cloth storage rack, then squeezing water in the base cloth to be dry through a squeeze roller, and ironing the base cloth to be half-dry through an ironing wheel; and 2, putting the half-dry base cloth on a coating table, uniformly coating the base cloth with the wear-resistant coating by adopting a coating knife coating method, then putting the base cloth into a curing tank for curing at the temperature of 40-60 DEG C, washing the cured cloth with water in a washing tank, and finally performing the procedures of drying, sizing, rolling, buffing and shearing to obtain the damping cloth with good wear resistance. The damping cloth has high wear resistance, and also has antibacterial and waterproof properties.

Owner:ANHUI HECHEN NEW MATERIAL CO LTD

Insulating resin composition with good flame retardant property

The invention discloses an insulating resin composition with a good flame retardant property. The insulating resin composition comprises the following raw materials: polypropylene resin, acrylate rubber, polyurethane rubber, polyisobutylene grafted maleic anhydride, a plasticizer, antimony trioxide, an antioxidant, an anti-aging agent, a cross-linking agent and an assistant crosslinker, and silicone rubber. The insulating resin composition is special in surface properties, low in water absorption, no breeding effect on various algae and molds, good in mold resistance, good in thermal conductivity and air permeability, greatly different in gas permeability of different gases, odorless and tasteless, and extremely good in antithrombotic properties and biological inertness, and used in combination with the polypropylene resin, the acrylate rubber and the polyurethane rubber, so that the heat resistance and the flexibility of the insulating resin composition are further improved.

Owner:吴辉

Preparation method of injectable double-cross-linked hydrogel for tissue engineering

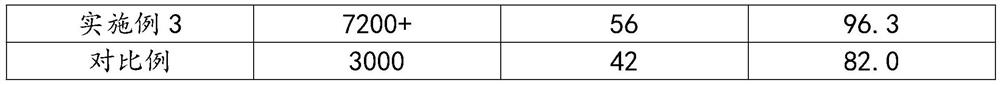

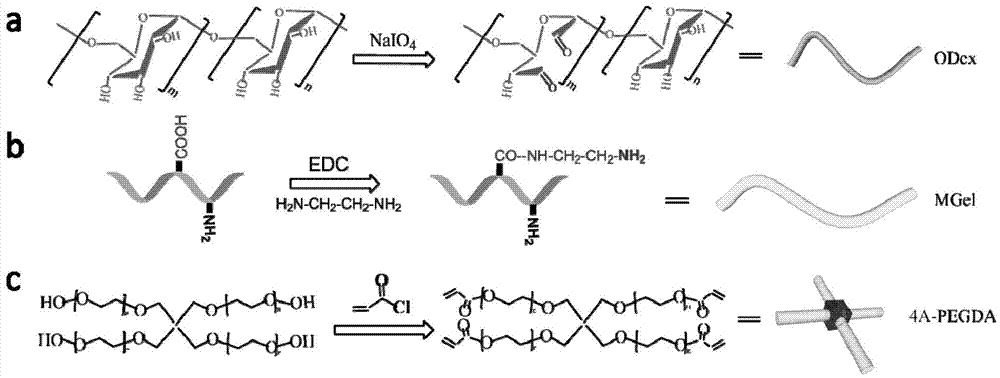

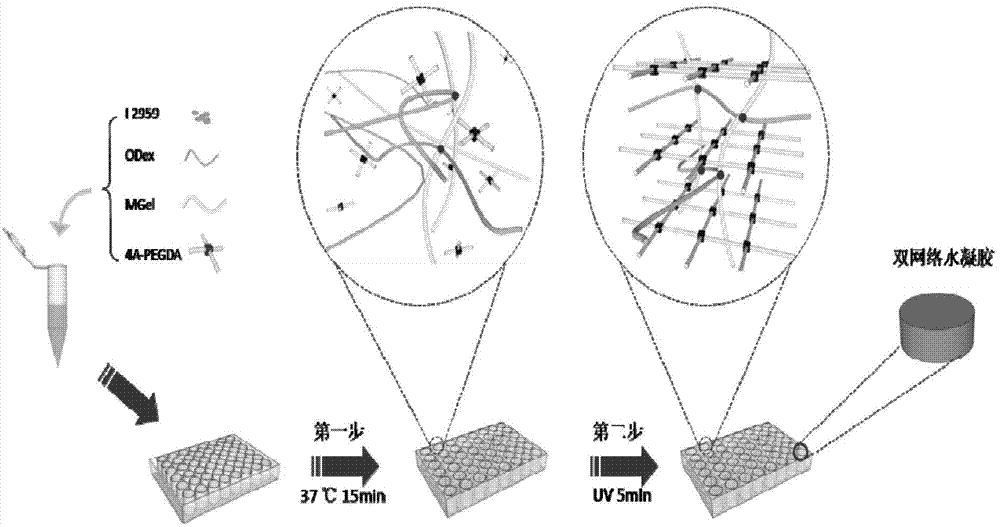

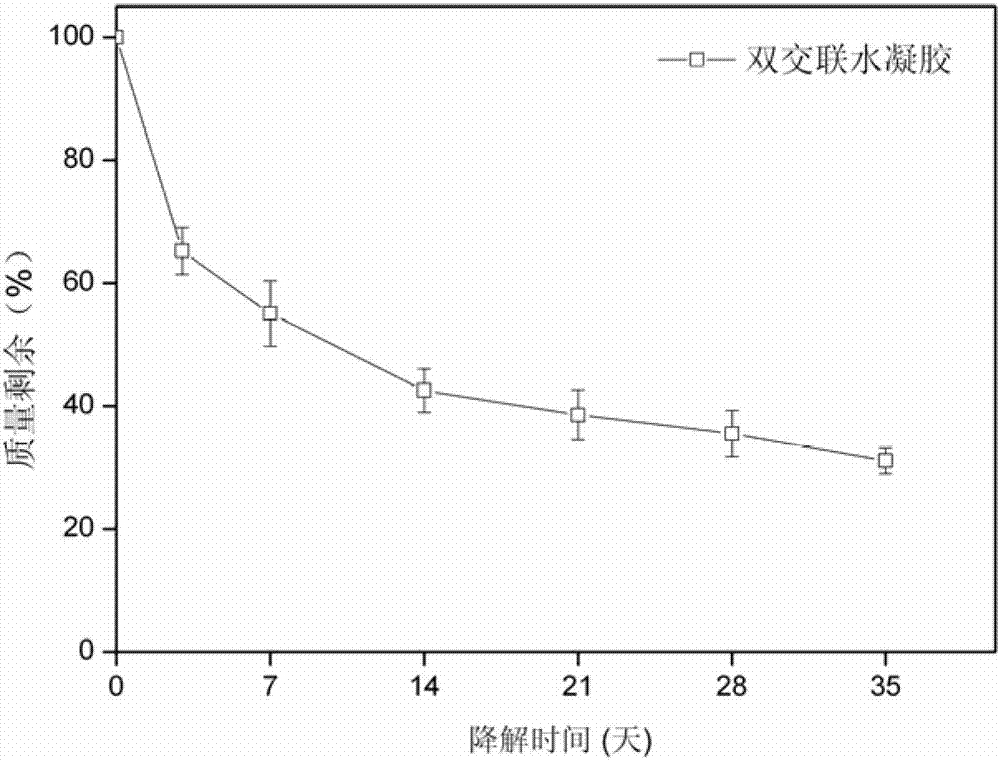

ActiveCN102784414BSimple operation processMild implementation conditionsProsthesisCross-linkPolyethylene glycol

Owner:烟台沃德麦克斯纳米科技有限公司

Insulating resin composition with good flexibility

InactiveCN108559210ARegular structureImprove mechanical propertiesRubber insulatorsAntioxidantPliability

The invention discloses an insulating resin composition with good flexibility. The insulating resin composition is prepared from the following raw materials: a polypropylene resin, polyacrylate rubber, polyurethane rubber, polyisobutene grafted maleic anhydride, a plasticizer, antimonous oxide, an antioxidant, an anti-aging agent, a crosslinking agent, an assistant crosslinker and silicon rubber.The insulating resin composition has special surface properties, is low in water absorption, has no propagation function on various algae and mold, is good in mold resistance, heat conduction and airpermeability, in addition has great air permeability differences for different gases, is non-odorous and tasteless, has very good thrombus resistance and biological nonreactivity, and can be used together with the polypropylene resin, the polyacrylate rubber and the polyurethane rubber, and the thermal resistance and the flexibility of the insulating resin composition can be further improved.

Owner:吴辉

Polymers, their preparation and applications

The invention is applicable to the field of polymer materials, and provides a polymer, its preparation method and application. The polymer has the following structural formula. The polymer of the present invention comprises a polyoxazoline group and a hydroxyl group, a carboxyl group, an amino group, a mercapto group, an azido group or a trimethyl (ethyl) oxysilyl group, and through the polyoxazoline group, the polymer of the present invention has Very excellent biological inertness, stability and ease of synthesis, through the active functional groups such as hydroxyl, carboxyl, amino, mercapto, azido or trimethyl(ethyl)oxysilyl, the polymer can be formed with other functional groups The cross-linking reaction greatly broadens the scope of application of the polymer; the preparation method of the polymer of the present invention realizes that the polymer has excellent biological inertia, stability and ease of use by introducing polyoxazoline groups and other active functional groups. Synthetic and capable of cross-linking reactions with other functional groups, it has a wide range of applications.

Owner:张昊 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com