Damping cloth with good wear resistance and preparation method thereof

A technology of wear resistance and damping cloth, which is applied in the direction of textiles and papermaking, and can solve the problems of poor quality, short service life, and easy breeding of bacteria and mildew in damping cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

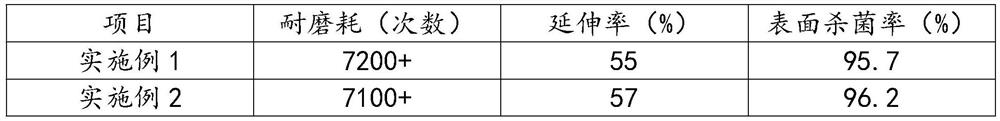

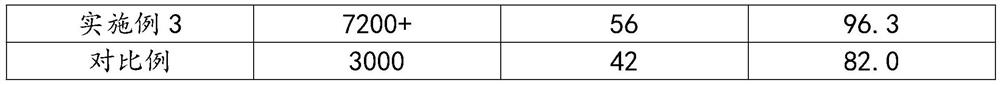

Examples

Embodiment 1

[0035] A damping cloth with good wear resistance, including base cloth and wear-resistant coating;

[0036] The damping cloth with good wear resistance is made by the following steps:

[0037] The first step, the base fabric is unrolled, and immersed in the immersion tank through the cloth storage rack. The immersion tank contains anionic surfactant and water with a mass ratio of 1:100. Iron the base cloth until it is half dry;

[0038] The second step is to place the semi-dry base cloth on the coating table, apply the wear-resistant coating evenly on the base cloth by the knife coating method, and then enter the curing tank to cure at a temperature of 40°C. The cured cloth After washing in a washing tank, and finally drying, shaping, winding, smoothing, and shearing, a damping cloth with good wear resistance is obtained.

[0039] The anionic surfactant is sodium dodecylbenzenesulfonate.

[0040] The preparation process of the wear-resistant coating is as follows:

[0041]...

Embodiment 2

[0055] A damping cloth with good wear resistance, including base cloth and wear-resistant coating;

[0056] The damping cloth with good wear resistance is made by the following steps:

[0057] The first step, the base fabric is unrolled, and immersed in the immersion tank through the cloth storage rack. The immersion tank contains anionic surfactant and water with a mass ratio of 1:100. Iron the base cloth until it is half dry;

[0058] The second step is to place the semi-dry base cloth on the coating table, apply the wear-resistant coating evenly on the base cloth by the knife coating method, and then enter the curing tank to cure at a temperature of 50°C. The cured cloth After washing in a washing tank, and finally drying, shaping, winding, smoothing, and shearing, a damping cloth with good wear resistance is obtained.

[0059] The anionic surfactant is sodium dodecylbenzenesulfonate.

[0060] The preparation process of the wear-resistant coating is as follows:

[0061]...

Embodiment 3

[0075] A damping cloth with good wear resistance, including base cloth and wear-resistant coating;

[0076] The damping cloth with good wear resistance is made by the following steps:

[0077] The first step, the base fabric is unrolled, and immersed in the immersion tank through the cloth storage rack. The immersion tank contains anionic surfactant and water with a mass ratio of 1:100. Iron the base cloth until it is half dry;

[0078] The second step is to place the semi-dry base cloth on the coating table, apply the wear-resistant coating evenly on the base cloth by the knife coating method, and then enter the curing tank to cure at a temperature of 60°C. The cured cloth After washing in a washing tank, and finally drying, shaping, winding, smoothing, and shearing, a damping cloth with good wear resistance is obtained.

[0079] The anionic surfactant is sodium dodecylbenzenesulfonate.

[0080] The preparation process of the wear-resistant coating is as follows:

[0081]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com