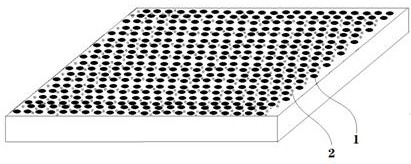

Polyurethane/ceramic composite biological filler for sewage treatment and preparation method

A bio-filler and ceramic composite technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, ceramic products, etc., can solve problems such as poor hydrophilicity and insufficient mechanical strength of organic fillers, and achieve enhanced bio-affinity performance, realize the utilization of resources, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Mix the anionic chain extender dimethylolpropionic acid (DMPA), dicyclohexylmethane diisocyanate, and polyethylene glycol 600 with a mass ratio of 0.05:0.5:1, and set the polymerization reaction temperature at 55°C. Add a triethylenediamine liquid catalyst with a ratio of 0.7:1 to the anionic chain extender to react to prepare a polyurethane prepolymer;

[0031] (2) According to the mass ratio of triethylamine, lactide and polyurethane prepolymer of 0.65:0.19:10, take triethylamine and lactide, and add an appropriate amount of polyurethane prepolymer prepared in step (1) Acetone, the amount of acetone added is 8% of the mass of the polyurethane prepolymer, then the temperature is lowered to 20°C, triethylamine and lactide are added and stirring is continued to obtain water-based polyurethane;

[0032] (3) After deodorizing the municipal sludge, put it into a blast drying oven at a temperature of 108°C for drying, crush and sieve the dried municipal sludge to obtain ...

Embodiment 2

[0036] (1) Mix the anionic chain extender 1,4-butanediol-2-sulfonate sodium, diphenylmethane diisocyanate and polyethylene glycol 600 with a mass ratio of 0.04:1.5:1, and set the polymerization reaction temperature At 75°C, add a triethylenediamine liquid catalyst with a mass ratio of 0.9:1 to the anionic chain extender to react to prepare a polyurethane prepolymer;

[0037] (2) According to the mass ratio of triethylamine, lactide and polyurethane prepolymer of 0.45:0.19:10, take triethylamine and lactide, and add an appropriate amount of polyurethane prepolymer prepared in step (1) Acetone, the amount of acetone added is 5% of the mass of the polyurethane prepolymer, then the temperature is lowered to 25°C, and triethylamine and lactide are added to continue stirring and emulsification to obtain a water-based composite polyurethane;

[0038] (3) After deodorizing the municipal sludge, put it into a blast drying oven at a temperature of 105°C for drying, crush and sieve the d...

Embodiment 3

[0042] (1) Mix the anionic chain extender dimethylolbutyric acid (DMBA), dicyclohexylmethane diisocyanate, and polyethylene glycol 600 with a mass ratio of 0.05:2.5:1, and set the polymerization reaction temperature at 40°C. Add a triethylenediamine liquid catalyst with a mass ratio of 1.3:1 to the anionic chain extender to react to prepare a polyurethane prepolymer;

[0043] (2) According to the mass ratio of triethylamine, lactide and polyurethane prepolymer of 0.72:0.21:10, take triethylamine and lactide, and add an appropriate amount of polyurethane prepolymer prepared in step (1) acetone, the amount of acetone added is 10% of the mass of the polyurethane prepolymer, then cooled to 25°C, adding triethylamine and lactide to continue stirring and emulsification to obtain a water-based composite polyurethane;

[0044] (3) After deodorizing the municipal sludge, put it into a blast drying oven at a temperature of 110°C for drying, crush and sieve the dried municipal sludge to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com