Multilayer co-squeeze film for transfusion

A film for infusion, multi-layer co-extrusion technology, applied in the field of film, can solve the problems of glass bottles with large shape and volume, easy to break, air pollution, etc., to avoid bacterial cross-infection, not afraid of mechanical force, good elasticity and flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

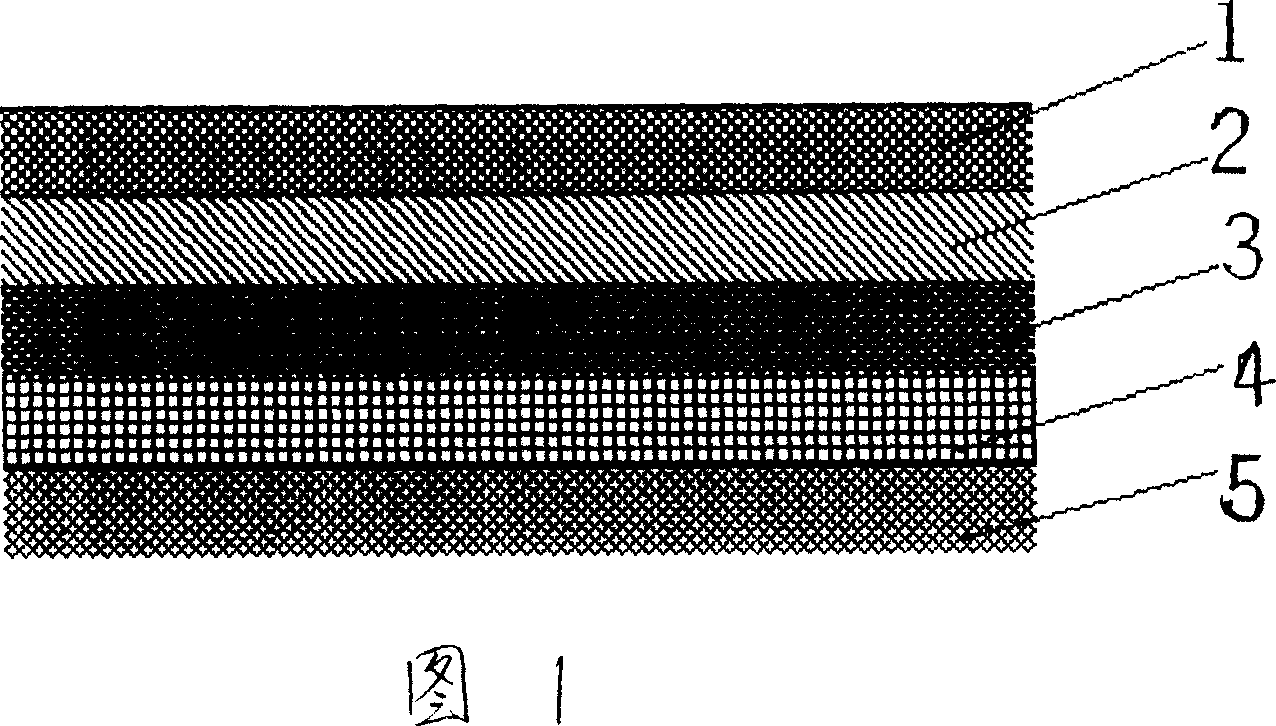

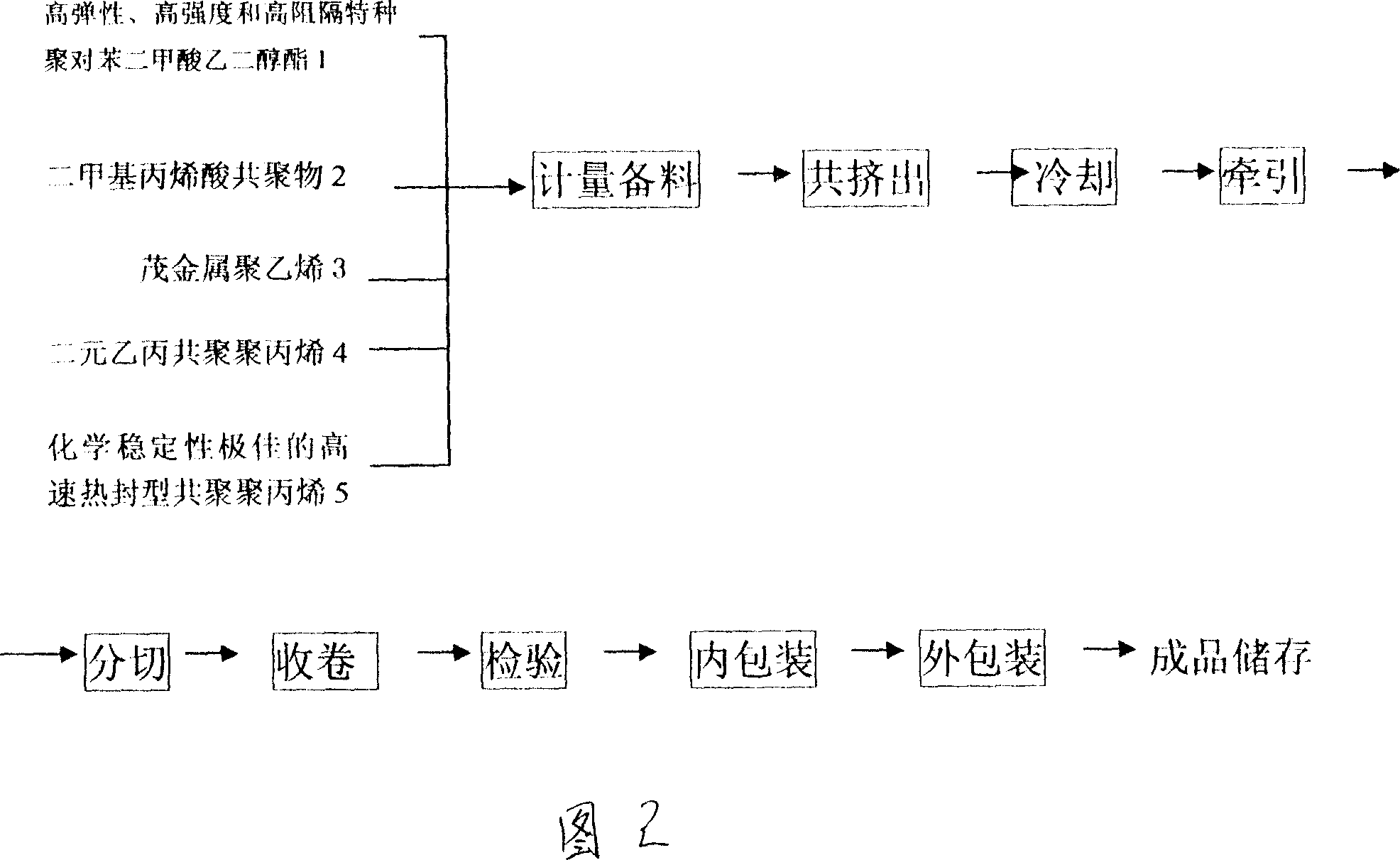

[0012] The present invention is a membrane for infusion, which is composed of five layers of polymer materials, which are as follows: the first layer is special polyethylene terephthalate 1 with high elasticity, high strength and high barrier; the second layer is two Methacrylic acid copolymer 2; the third layer is metallocene polyethylene 3; the fourth layer is binary ethylene-propylene copolymer polypropylene 4; the fifth layer is high-speed heat-sealable copolymer polypropylene 5 with excellent chemical stability.

[0013] The machine head used in the production of the present invention is designed according to the different processing techniques and designed temperatures of various resins of the product. The characteristic of the machine head is that each flow channel has a temperature-insulating barrier layer, and the machine head structure is the most advanced in the world. Advanced tapered superimposed compound head.

[0014] The principle of the present invention is: i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com