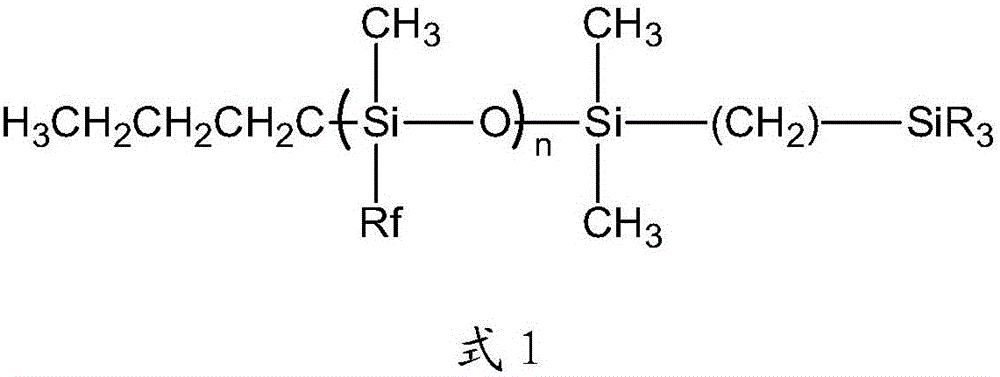

Fluorine-containing polysiloxane non-stick additive as well as preparation method and application thereof

A technology of polysiloxane and adhesion aid, which is applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve problems such as poor non-stick durability, and achieve low surface energy and good biological inertness. , Improve the effect of non-stick durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

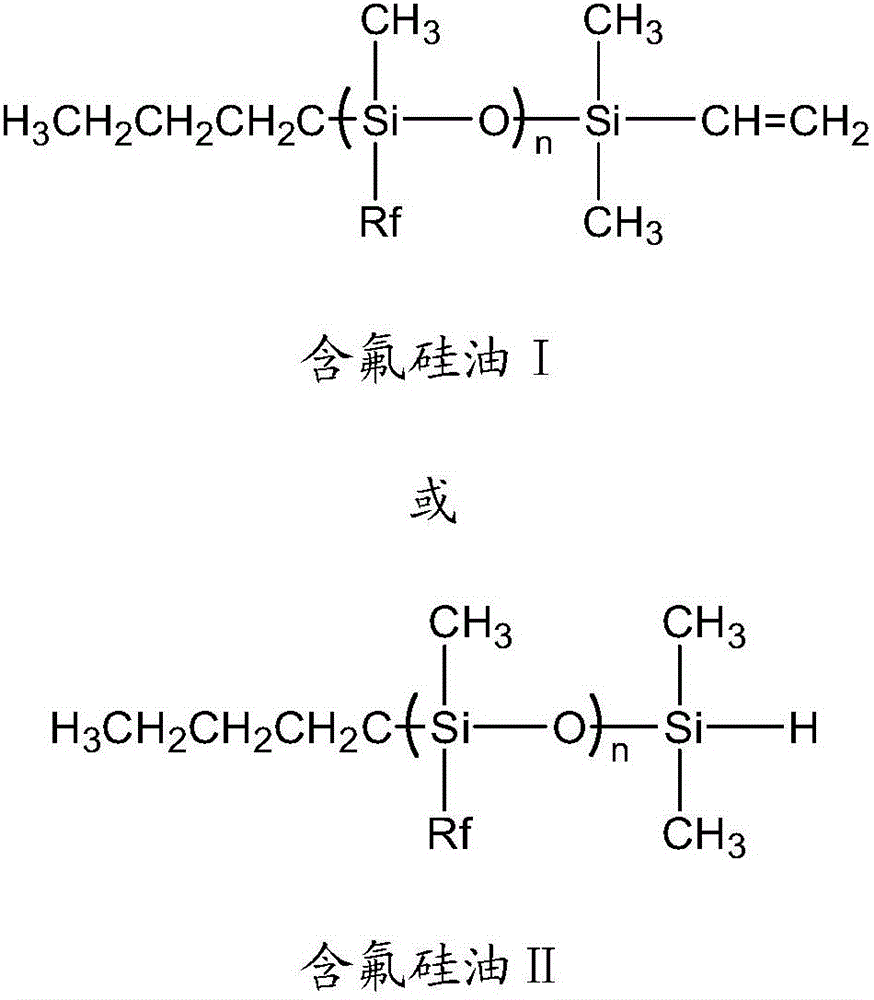

Method used

Image

Examples

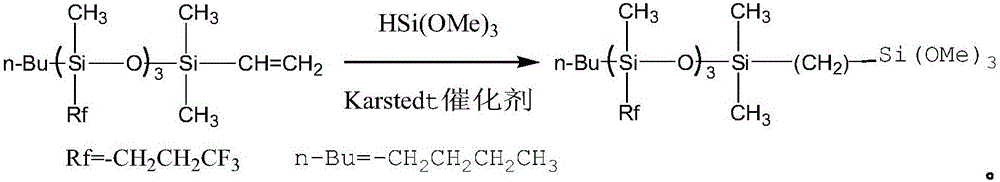

Embodiment 1

[0033] First vacuum the reaction device to 1×10 -1 Pa, remove oxygen and moisture, then pass through nitrogen protection, add 50 parts by weight of fluorine-containing silicone oil I (n=3, Rf is -CH 2 CH 2 CF 3 ), 6 parts by weight of trimethoxysilane, 30 ppm of Karstedt catalyst, 10 parts by weight of THF, after stirring evenly, react at 60 ° C for 5 hours, and the product removes THF and excess silane to obtain fluorine-containing polysiloxane Non-stick additives1.

[0034] Its synthetic route is as follows:

[0035]

Embodiment 2

[0037] First vacuum the reaction device to 1×10 -1 Pa, remove oxygen and moisture, then pass through nitrogen protection, add 50 parts by weight of fluorine-containing silicone oil I (n=6, Rf is -CH 2 CH 2 CF 2 CF 2 CF 2 CF 3 ), 3 parts by weight of triethoxysilane, 20 ppm of Karstedt catalyst, 20 parts by weight of solvent, after stirring evenly, react at 60°C for 3 hours, and the product removes THF and excess silane to obtain fluorine-containing polysiloxane Alkane non-stick additives 2.

[0038] Its synthetic route is as follows:

[0039]

Embodiment 3

[0041] First vacuum the reaction device to 1×10 -1 Pa, remove oxygen and moisture, then pass through nitrogen protection, add 50 parts by weight of fluorine-containing silicone oil I (n=50, Rf is -CH 2 CH 2 CF 2 CF 2 CF 2 CF 2 CF 2 CF 3 ), 0.5 parts by weight of trimethoxysilane, 10 ppm of Karstedt catalyst, 30 parts by weight of solvent, after stirring evenly, reacted at 60 ° C for 8 hours, and the product was desolvated to obtain a fluorine-containing polysiloxane non-stick additive 3.

[0042] Its synthetic route is as follows:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com