Three-layer coextrusion film for infusion and preparation method of three-layer coextrusion film

A three-layer co-extrusion film technology for infusion, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as unstable interfaces, affecting the clarity of drugs, and hidden dangers to the health of patients. Achieve the effects of improving interface bonding performance, avoiding bacterial cross-infection, and good biological inertness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

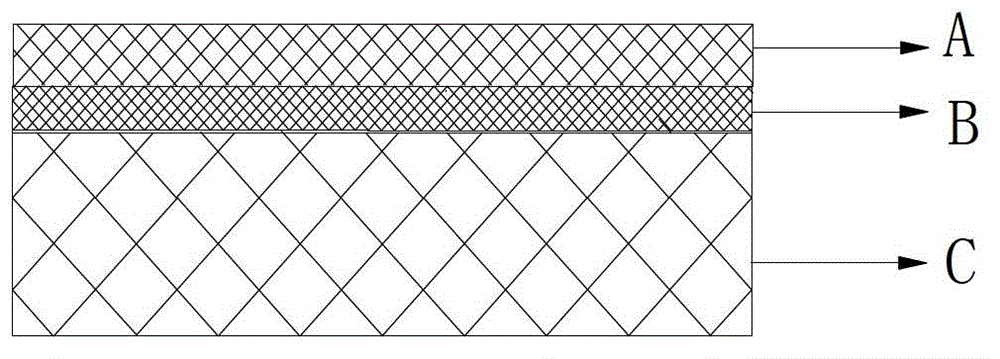

[0035] Such as figure 1 Shown is the distribution of each layer of the three-layer co-extrusion infusion membrane of the present invention. Depend on figure 1 It can be seen that the three-layer co-extrusion infusion membrane of the present invention is composed of the inner layer A, the adhesive layer B, and the outer layer C respectively in terms of structural composition.

[0036] The random copolymer polypropylene used in the inner layer A has a melt index of 2-10g / 10min and a density of 0.88-0.92g / cm 3 , and the thickness accounts for 15%-35% of the total thickness of the co-extrusion infusion film.

[0037] The ethylene vinyl acetate copolymer EVA used in the adhesive layer B has a melt index of 2-10 g / min and a density of 0.91-0.95 g / cm 3 , and the thickness accounts for 15%-20% of the total thickness of the co-extruded infusion film.

[0038] The polyvinyl chloride resin used in the inner layer C has a melt index of 2-10g / min and a density of 1.1-1.3g / cm 3 , and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com