Heat-resistant insulating resin composition

An insulating resin and composition technology, applied in the field of polymer materials, can solve the problems of high production cost, poor mechanical properties and heat resistance of the resin composition, and achieve high tear strength, good mildew resistance, and improved Effects of heat resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

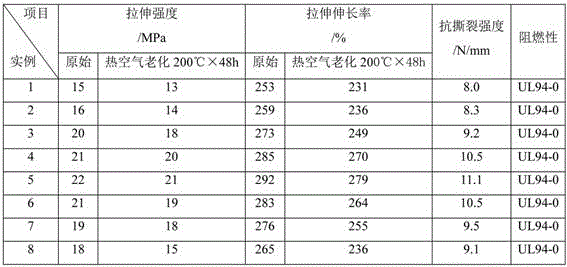

Examples

Embodiment 1

[0021] A heat-resistant insulating resin composition, comprising the following raw materials in parts by weight: 60 parts of polypropylene resin, 22 parts of acrylate rubber, 15 parts of polyurethane rubber, 7 parts of polyisobutylene grafted maleic anhydride, plasticizer 15 parts, 5 parts of flame retardant, 5 parts of antioxidant, 3 parts of anti-aging agent, 4 parts of cross-linking agent and 1 part of auxiliary cross-linking agent.

[0022] Described plasticizer is dibutyl phthalate.

[0023] The flame retardant is antimony trioxide.

[0024] The antioxidants are antioxidant 1010 and antioxidant 1076, and the mass ratio of the two is 0.5:1.

[0025] The anti-aging agents are anti-aging agent MB and anti-aging agent 4010NA, and the weight ratio of the two is 1:1.

[0026] The cross-linking agent is benzoyl peroxide.

[0027] The auxiliary crosslinking agent is N-N m-phenylene bismaleimide.

[0028] The preparation method of the heat-resistant insulating resin compositio...

Embodiment 2

[0031] A heat-resistant insulating resin composition, comprising the following raw materials in parts by weight: 63 parts of polypropylene resin, 25 parts of acrylate rubber, 16 parts of polyurethane rubber, 8 parts of polyisobutylene grafted maleic anhydride, plasticizer 18 parts, 5 parts of flame retardant, 6 parts of antioxidant, 4 parts of antiaging agent, 4 parts of crosslinking agent and 1.1 parts of auxiliary crosslinking agent.

[0032] Described plasticizer is dioctyl phthalate.

[0033] The flame retardant is molybdenum dioxide.

[0034] The antioxidants are antioxidant 1010 and antioxidant 1076, and the mass ratio of the two is 1:1.

[0035] Described anti-aging agent is anti-aging agent MB and anti-aging agent 4010NA, and the weight ratio of the two is 2:1.

[0036] The crosslinking agent is 1,1-bis(tert-butyl peroxide) 3,3,5-trimethylcyclohexane.

[0037] The auxiliary crosslinking agent is triallyl isocyanurate.

[0038] See Example 1 for the preparation meth...

Embodiment 3

[0040] A heat-resistant insulating resin composition, comprising the following raw materials in parts by weight: 66 parts of polypropylene resin, 28 parts of acrylate rubber, 18 parts of polyurethane rubber, 10 parts of silicone rubber, 9 parts of polyisobutylene grafted maleic anhydride 20 parts of plasticizer, 6 parts of flame retardant, 7 parts of antioxidant, 5 parts of anti-aging agent, 5 parts of crosslinking agent and 1.3 parts of co-crosslinking agent.

[0041] Described plasticizer is didecyl phthalate.

[0042] The flame retardant is magnesium hydroxide and calcium carbonate, and the mass ratio of the two is 1:1.

[0043] The antioxidants are antioxidant 1010 and antioxidant 1076, and the mass ratio of the two is 2:1.

[0044] The anti-aging agent is anti-aging agent MB and anti-aging agent 4010NA, and the weight ratio of the two is 0.5:1.

[0045] The cross-linking agent is dicumyl peroxide.

[0046] The auxiliary crosslinking agent is trimethylolpropane trimetha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com