Method for preparing lining material of fire hose

A fire hose and lining technology, which is applied in the field of preparation of fire hose lining materials, can solve the problems of oil resistance and poor corrosion resistance, and achieve the effects of good corrosion resistance, corrosion inhibition, and improved oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

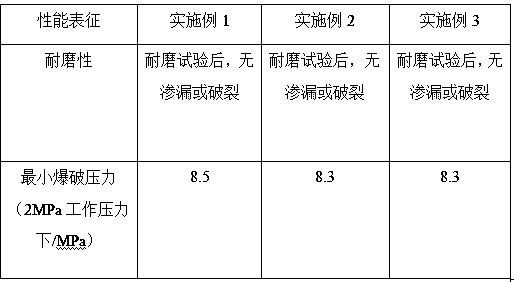

Examples

Embodiment 1

[0030] Take silicon rubber, cerium oxide, aluminum alloy powder, and dicumyl peroxide, place the silicon rubber in an open mill, and carry out mixing treatment to obtain rubber compound A. Add cerium oxide, Aluminum alloy powder and dicumyl peroxide, continue to mix for 20 minutes to obtain compound rubber B, and carry out rolling and sheeting treatment on compound rubber B to obtain the precursor, and perform a vulcanization treatment on the precursor to obtain Primary sulfide, the primary sulfide is subjected to secondary vulcanization treatment, cooled to room temperature, and the body is obtained; Zn(NO 3 ) 2 ·6H 2 O and NH 4 NO 3 Mix and stir to obtain a mixed solution, adjust the pH value of the mixed solution to obtain a reaction solution; wash the green body with acetone and deionized water for 3 to 5 times, and dry it naturally to obtain a pretreated green body. Hang the pretreated green body vertically in the reaction solution, soak it, filter to obtain the filte...

Embodiment 2

[0032] Take silicon rubber, cerium oxide, aluminum alloy powder, and dicumyl peroxide, place the silicon rubber in an open mill, and carry out mixing treatment to obtain rubber compound A. Add cerium oxide, Aluminum alloy powder and dicumyl peroxide, continue to mix for 25 minutes to obtain compound rubber B, and carry out rolling and sheeting treatment on compound rubber B to obtain a precursor, which is subjected to a vulcanization treatment once to obtain Primary sulfide, the primary sulfide is subjected to secondary vulcanization treatment, cooled to room temperature, and the body is obtained; Zn(NO 3 ) 2 ·6H 2 O and NH 4 NO 3 Mix and stir to obtain a mixed solution, adjust the pH value of the mixed solution to obtain a reaction solution; wash the green body with acetone and deionized water for 4 times, and dry it naturally to obtain a pretreated green body. The treated blank is hung vertically in the reaction solution, soaked, filtered to obtain the filter residue, wa...

Embodiment 3

[0034] Take silicon rubber, cerium oxide, aluminum alloy powder, and dicumyl peroxide, place the silicon rubber in an open mill, and carry out mixing treatment to obtain rubber compound A. Add cerium oxide, Aluminum alloy powder and dicumyl peroxide, continue to mix for 30 minutes to obtain compound rubber B, and carry out rolling and sheeting treatment on compound rubber B to obtain a precursor, and perform a vulcanization treatment on the precursor to obtain Primary sulfide, the primary sulfide is subjected to secondary vulcanization treatment, cooled to room temperature, and the body is obtained; Zn(NO 3 ) 2 ·6H 2 O and NH 4 NO 3 Mix and stir to obtain a mixed solution, adjust the pH value of the mixed solution to obtain a reaction solution; wash the green body with acetone and deionized water for 5 times, and dry it naturally to obtain a pretreated green body. The treated body is hung vertically in the reaction solution, soaked, filtered to obtain the filter residue, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com