Bacterial cellulose-Nafion sandwich proton exchange membrane and preparation and application thereof

A bacterial cellulose membrane, bacterial cellulose technology, applied in bacterial cellulose-Nafion sandwich proton exchange membrane and its preparation and application fields, can solve problems such as low proton conductivity, achieve high proton conductivity, good thermal stability, The effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

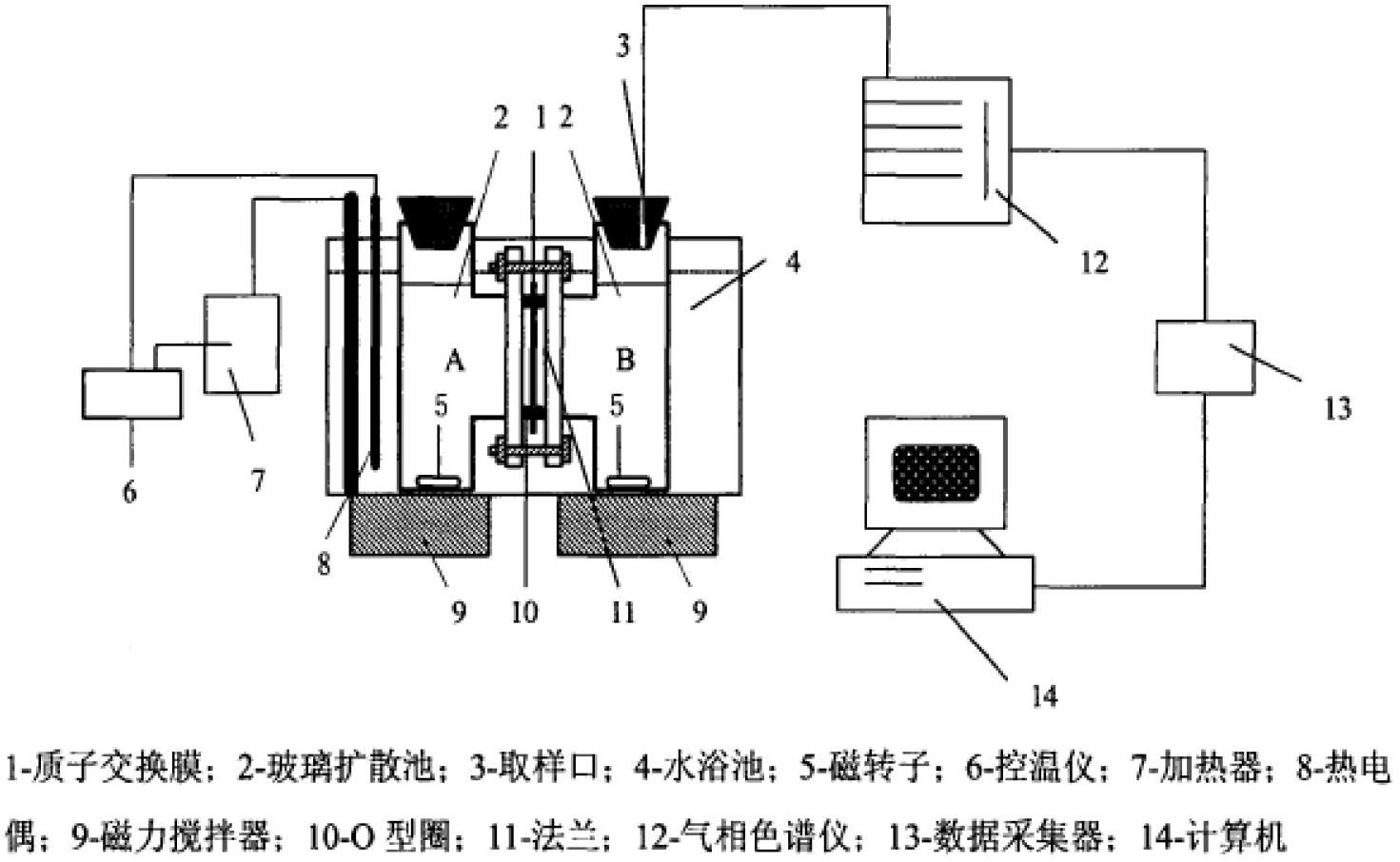

Method used

Image

Examples

Embodiment 1

[0034] (1) Take the bacterial cellulose membrane, wash it with deionized water to remove impurities such as residual culture medium, and then place it in a 1% by mass sodium hydroxide solution at 80°C for 2 hours until the bacterial cellulose membrane turns white It is translucent, then cleaned with deionized water, boiled in deionized water for 1 hour, taken out and rinsed with deionized water until the pH value of the surface of the bacterial cellulose membrane is neutral. At the same time, take the boiled extract to measure its 280nm absorption value, if the absorbance is not lower than 0.05, repeat the steps of boiling and rinsing until the boiled extract has no significant absorption at 280nm;

[0035] (2) Nafion115 membrane was boiled with 3% hydrogen peroxide, deionized water, 1mol / L dilute sulfuric acid and deionized water for 1 hour in sequence, and stored in deionized water.

[0036] (3) Take the treated Nafion115 membrane and cut it into a shape slightly smaller tha...

Embodiment 2

[0046] (1) Take the bacterial cellulose membrane, wash it with deionized water to remove impurities such as residual medium, and then place it in a 1% by mass potassium hydroxide solution for 2 hours at 80°C in a water bath until the bacterial cellulose membrane turns white Translucent, then wash with 0.1% acetic acid aqueous solution and deionized water, boil in deionized water for 1 hour, take it out and rinse with deionized water until the pH value of the surface of the bacterial cellulose membrane is neutral. At the same time, take the boiled extract to measure its 280nm absorption value, if the absorbance is not lower than 0.05, repeat the steps of boiling and rinsing until the boiled extract has no significant absorption at 280nm;

[0047] (2) The Nafion212 membrane was boiled with 3% hydrogen peroxide, deionized water, 1mol / L dilute sulfuric acid and deionized water for 1 hour, and stored in deionized water.

[0048] (3) Take the treated Nafion212 membrane and cut it in...

Embodiment 3

[0058] (1) Take the bacterial cellulose membrane, wash it with deionized water to remove impurities such as residual medium, and then place it in a 5% potassium carbonate solution by mass at 95°C for 1 hour until the bacterial cellulose membrane turns white and semi-white. Transparent, then wash with 0.1% phosphoric acid aqueous solution and deionized water, boil in deionized water for 2 hours, take it out and rinse with deionized water until the surface pH of the bacterial cellulose membrane is neutral. At the same time, take the boiled extract to measure its 280nm absorption value, if the absorbance is not lower than 0.05, repeat the steps of boiling and rinsing until the boiled extract has no significant absorption at 280nm;

[0059] (2) Nafion115 membrane and Nafion212 membrane were boiled with 3% hydrogen peroxide, deionized water, 1mol / L dilute sulfuric acid and deionized water for 1 hour, and stored in deionized water.

[0060] (3) Take the treated Nafion115 membrane or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

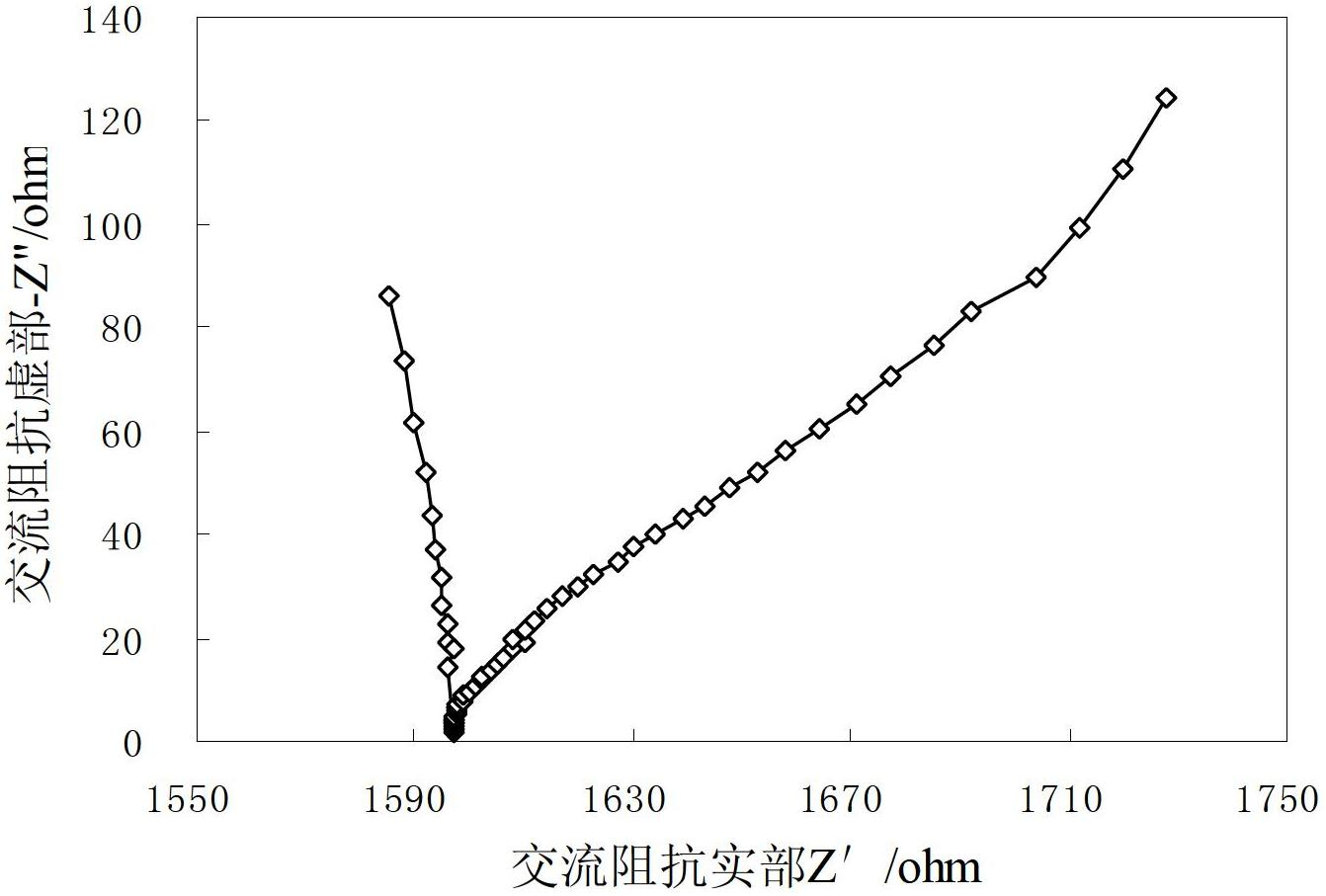

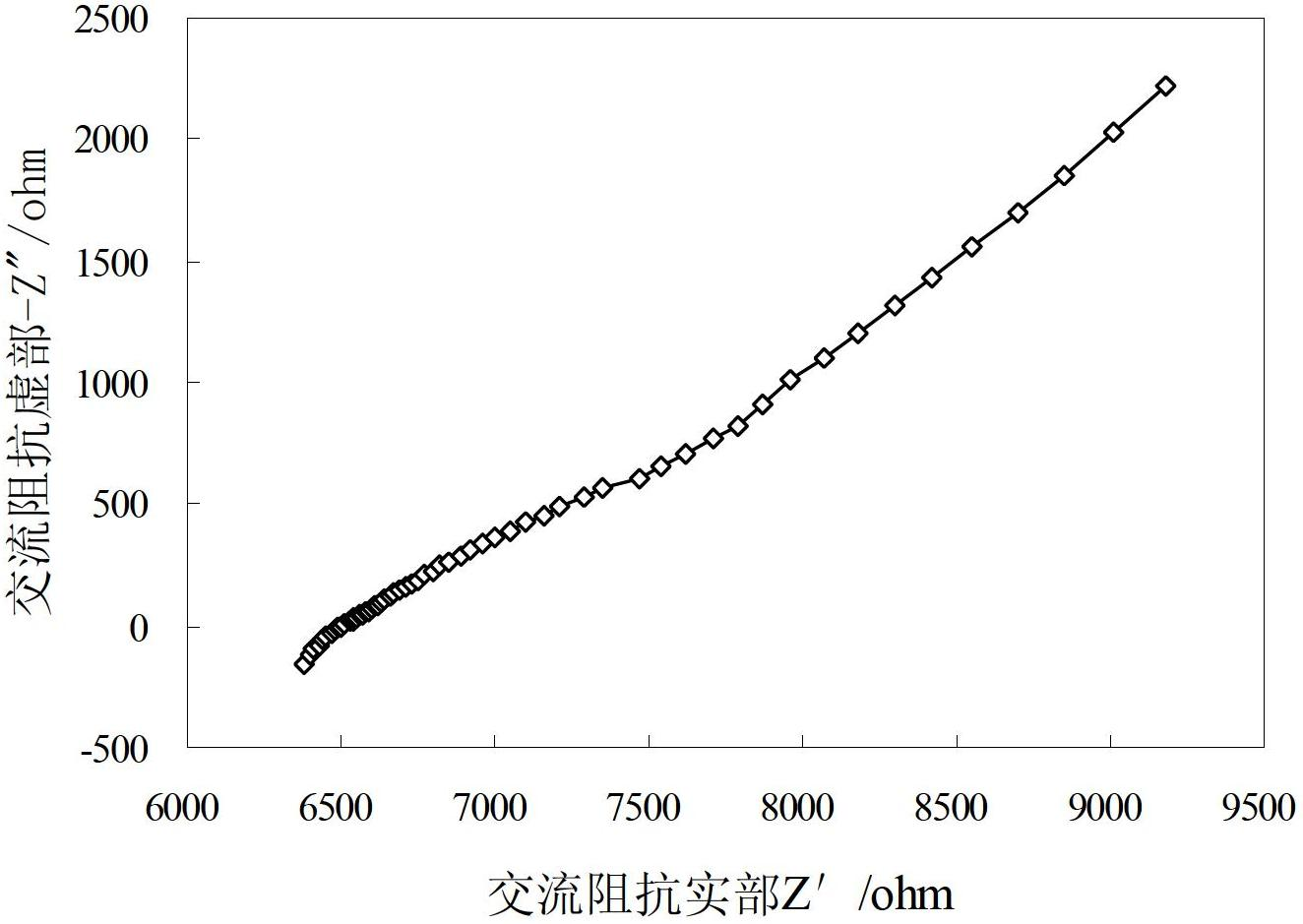

| Ac impedance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com