Silvering touch finger electroplating hanger of circuit breaker

A technology of electroplating racks and circuit breakers, which is applied in the direction of circuits, electric switches, and electrical components, can solve problems such as low production efficiency, resource waste costs, and low production efficiency, so as to ensure electroplating efficiency, avoid production efficiency constraints, and reduce production efficiency. The Effect of Plating Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

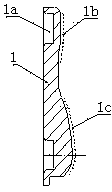

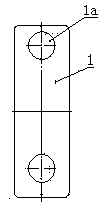

[0019] figure 1 , 2 It shows the structure of the silver-plated contact fingers of the circuit breaker. The back of the contact finger 1 is flat and has a pair of blind holes 1a. The front of the contact finger 1 has two arc-shaped protrusions, which are the contact fingers For the moving contact area, the dotted line parts 1b and 1c in this figure project the moving contact area of the contact finger that needs to be silver-plated.

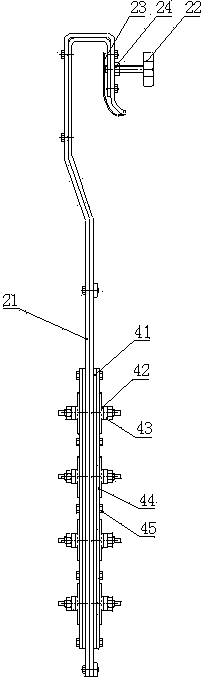

[0020] Such as image 3 , 4 , 5, the present invention discloses a circuit breaker silver-plated finger electroplating hanger, including electroplating bracket 21, conductive components, shielding components;

[0021] A pair of electroplating brackets 21, the electroplating bracket 21 is a metal piece consisting of a hook-shaped section with an upper opening downward and a vertical section at the bottom; a horizontal locking bolt 22 is threaded on the hook-shaped section, and the locking bolt 22 extends One end in the opening of the hook se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com