Jetting electroplating method directly of nozzle

A nozzle and jet flow technology, which is applied in the field of nozzle vertical jet flow electroplating, can solve the problems of low TP value of high aspect ratio backplane penetration capability, accelerated cracking of electroplating additives, and high cost, so as to improve the electroplating penetration capability and improve The effect of low potion concentration and electroplating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: the present invention carries out electroplating operation by following method:

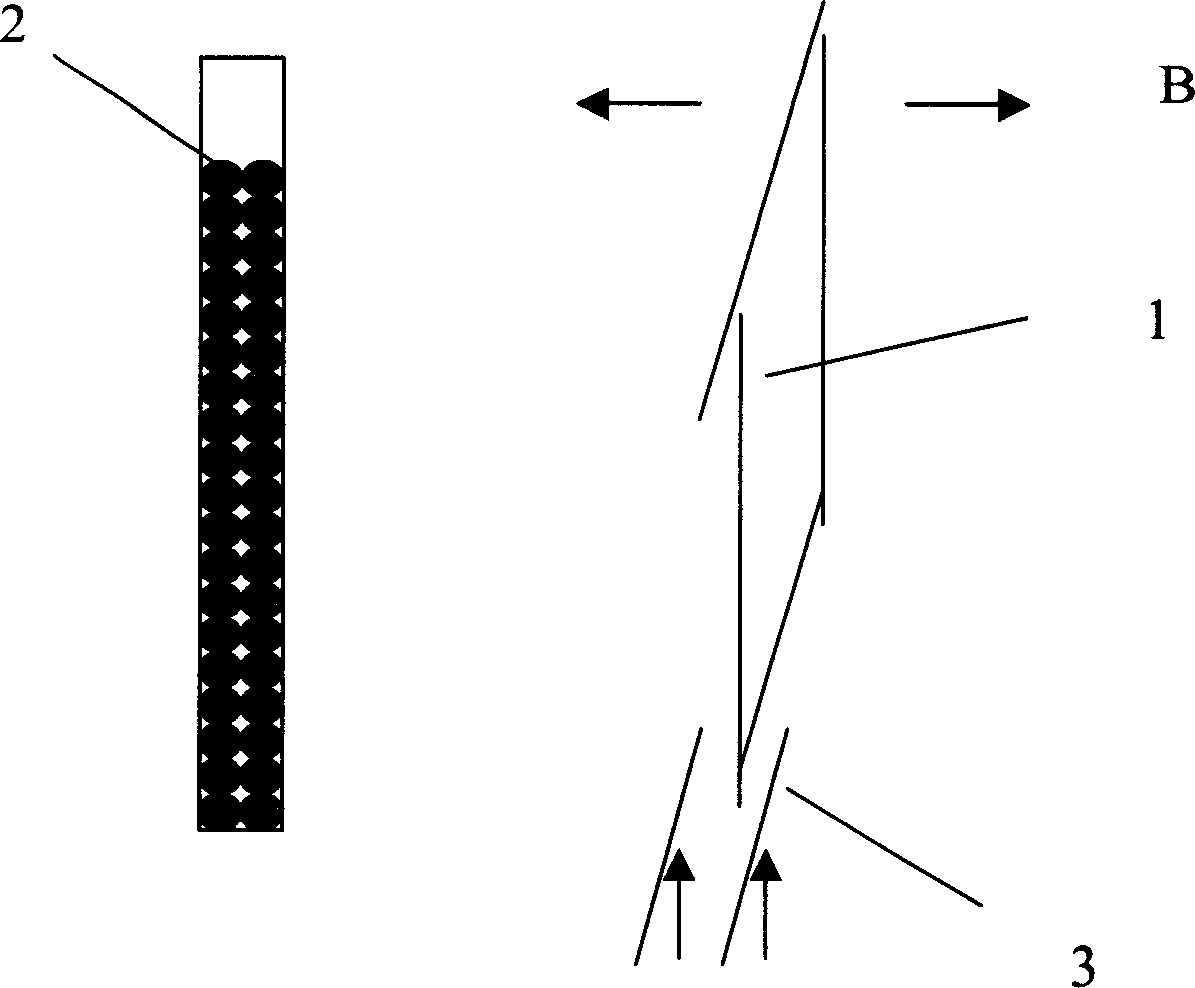

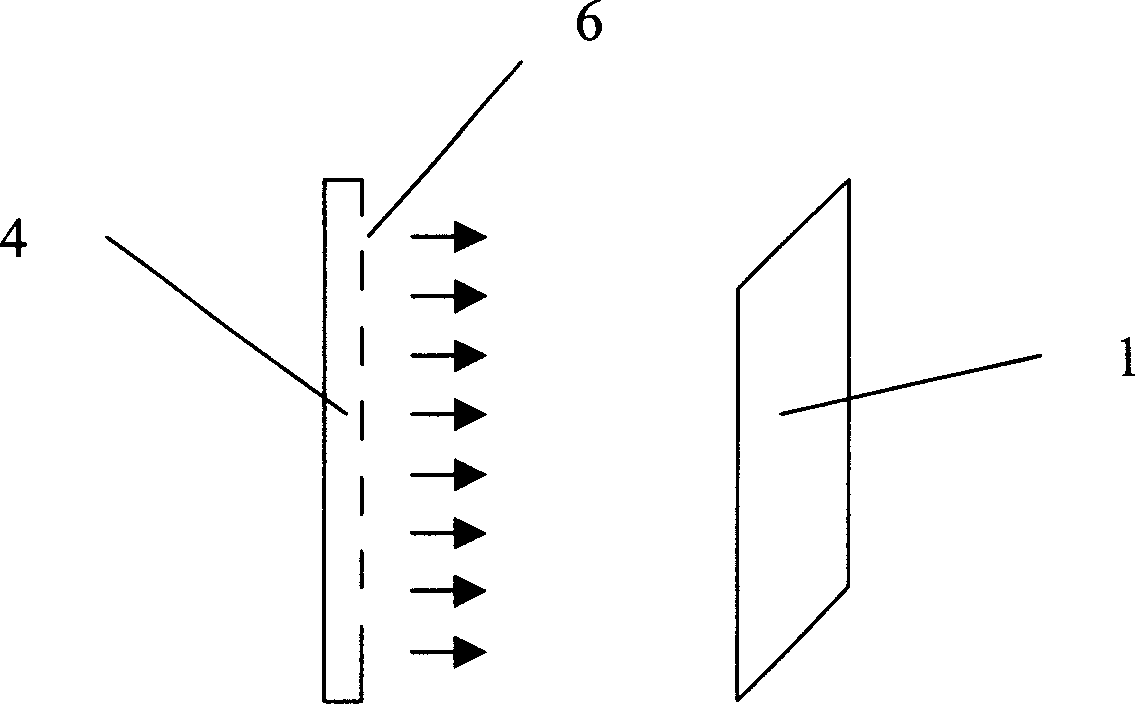

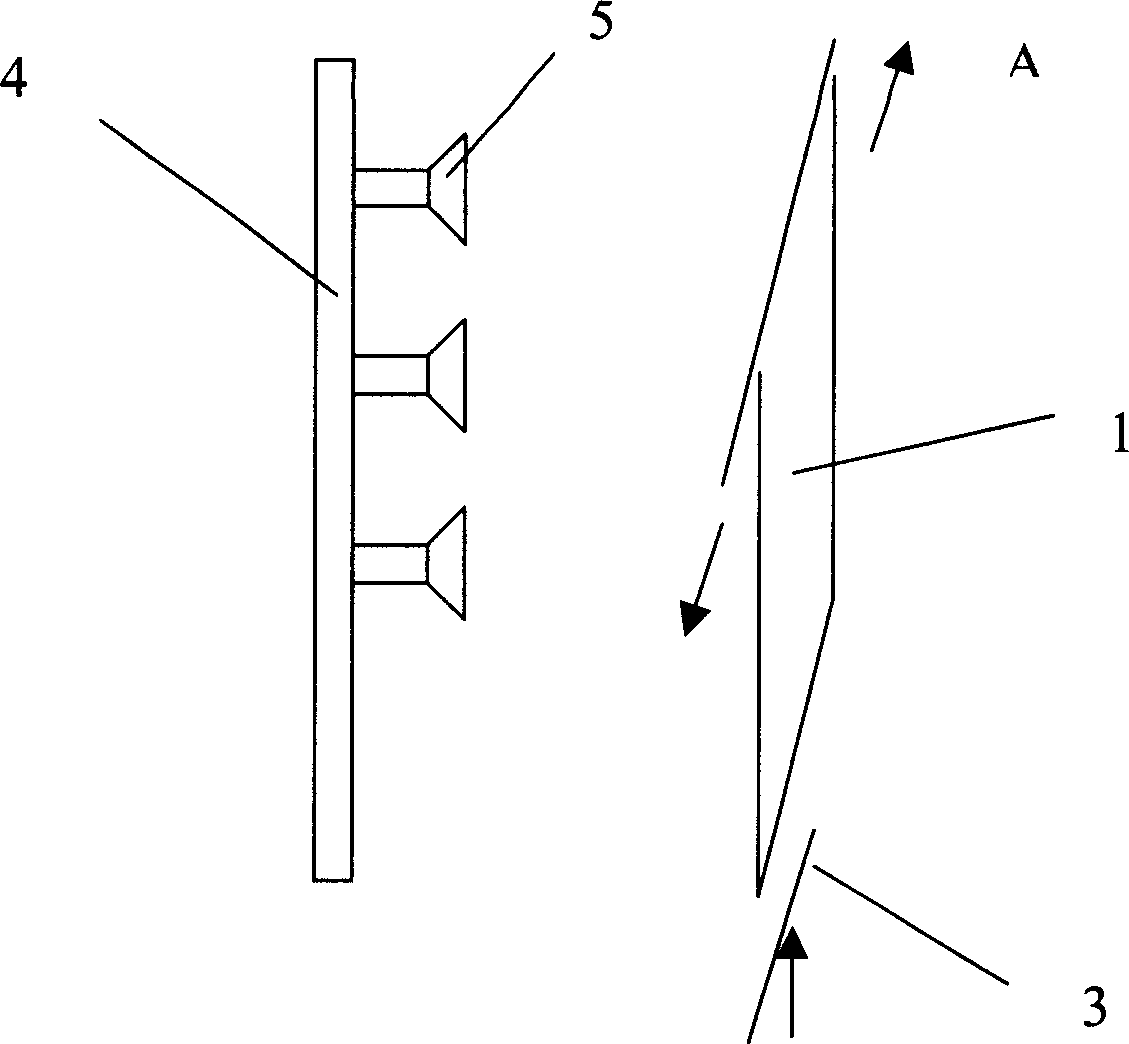

[0025] The anode titanium basket 2 and the cathode PCB board 1 are placed in the same electroplating bath, and a plurality of nozzles 4 are arranged in the gaps between a plurality of anode titanium baskets close to the tank wall, and a plurality of nozzles 5 are arranged on each nozzle, and electroplating The liquid is pumped out by the pump and sprayed out from the nozzle through the nozzle, and the spray flow is perpendicular to the PCB board surface 1, forcing the liquid medicine exchange inside and outside the hole; and, using the horizontal swing in the direction A perpendicular to the spray flow direction of the nozzle, so that all places in the PCB board surface The potion is delivered evenly.

[0026] In addition, the gas pipe 3 at the lower end of the tank body is changed from two to one, and it is only opened for use when the tank body is treated with activated carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com