Nano twin-crystal nickel with extremely small twin-crystal lamella thickness and ultrahigh strength and preparation thereof

A nano-twin, lamellar thickness technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve problems such as low hardness, limit industrial applications, etc., achieve high thermal stability, microstructure The effect of excellent, high thermal and mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

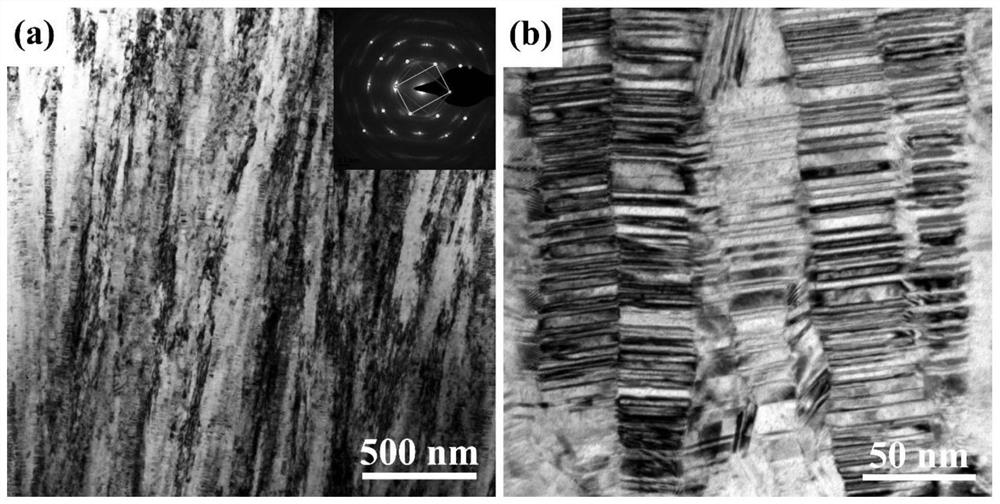

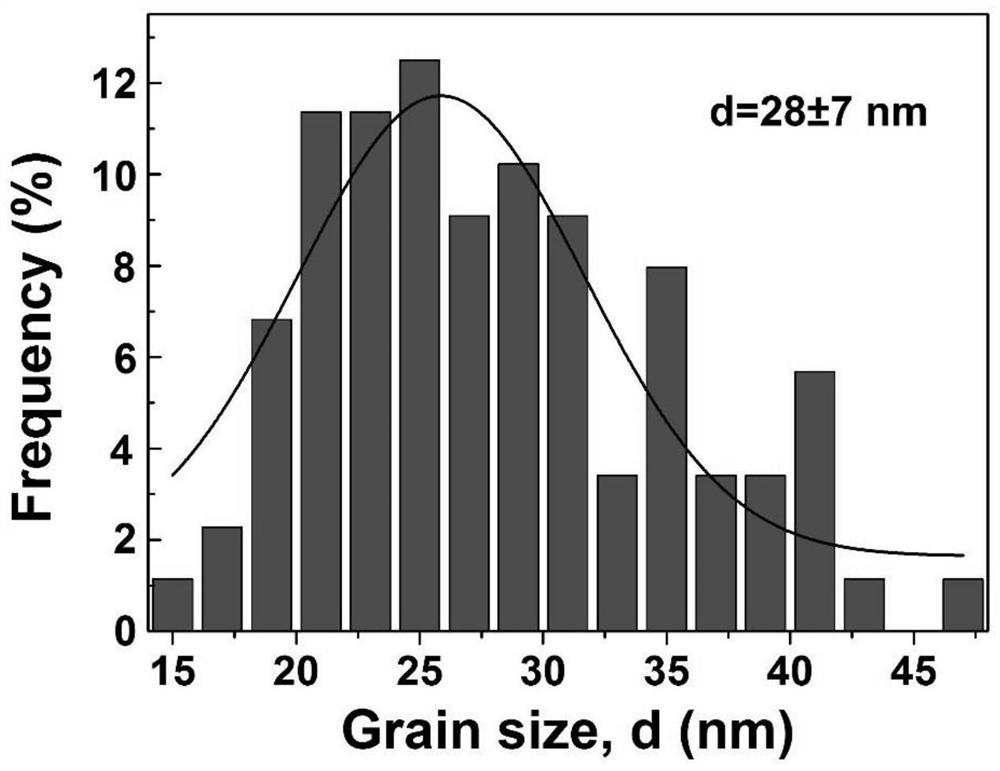

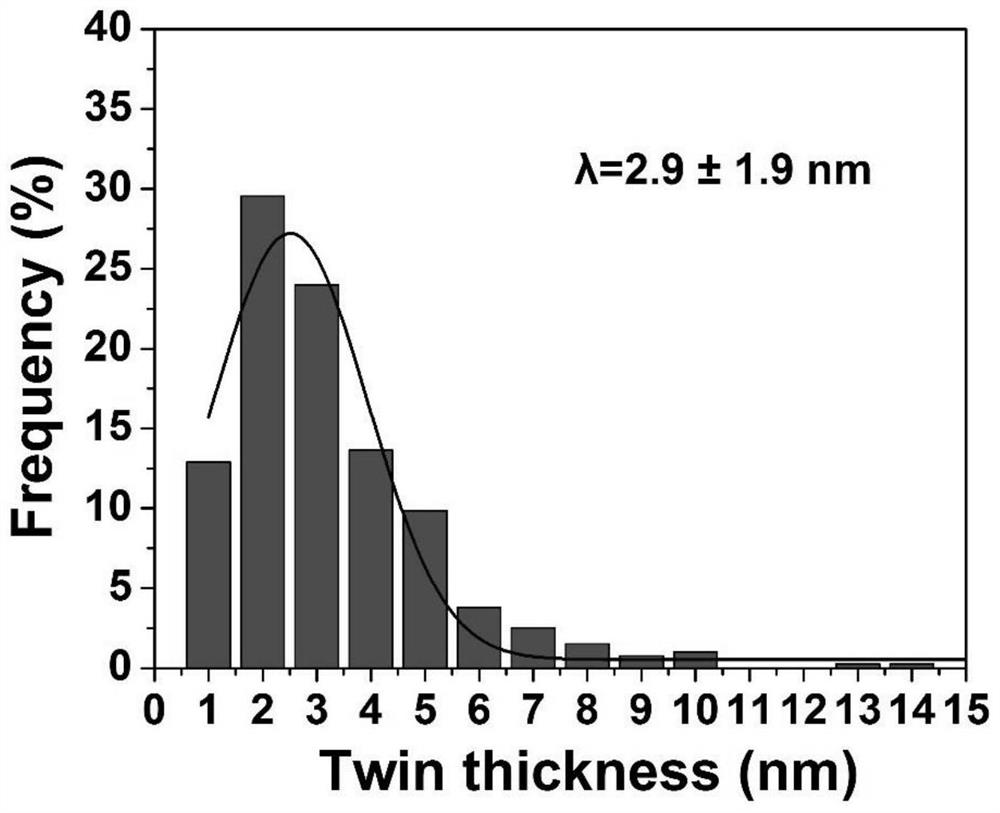

[0031] 1) Preparation of nano-twinned nickel with extremely small twinned layer thickness by electrolytic deposition

[0032] Electrodeposition equipment: DC power supply

[0033] Electrolyte solution formula: 200g / L nickel sulfate hexahydrate, 30g / L nickel chloride hexahydrate, 40g / L boric acid; additives are sodium lauryl sulfate 0.05g / L, sodium saccharin 2.5g / L, 1,4 butyl Alkyne diol 0.64g / L, glacial acetic acid 0.05g / L; all the above reagents were dissolved in deionized water, stirred and dissolved, and then filtered through filter paper; adjust the pH value to 3.5 with 10% dilute sulfuric acid;

[0034] Cathode and anode requirements: the anode is a pure nickel plate with a purity of 99.6wt.%, and the cathode is a nickel substrate after surface degreasing and sensitization treatment.

[0035] 2) Electrolysis process parameters: DC current density is 30mA / cm 2 , The temperature of the electrolyte is 70±1°C, the area ratio of cathode and anode is 1:50, the distance betwee...

Embodiment 2

[0042] 1) Preparation of nano-twinned nickel with extremely small twinned layer thickness by electrolytic deposition

[0043] Electrodeposition equipment: DC power supply

[0044] Electrolyte solution formula: 250g / L nickel sulfate hexahydrate, 40g / L nickel chloride hexahydrate, 40g / L boric acid; additives are sodium lauryl sulfate 0.06g / L, sodium saccharin 2.0g / L, 1,4 butyl Alkyne diol 0.74g / L, glacial acetic acid 0.07g / L; all the above reagents were dissolved in deionized water, stirred and dissolved, and then filtered through filter paper; adjust the pH value to 3.8 with 10% dilute sulfuric acid;

[0045] Cathode and anode requirements: the anode is a pure nickel plate with a purity of 99.6wt.%, and the cathode is a nickel substrate after surface degreasing and sensitization treatment.

[0046] 2) Electrolysis process parameters: DC current density is 70mA / cm 2 , the temperature of the electrolyte is 65±1°C, the area ratio of cathode and anode is 1:50, the distance betwee...

Embodiment 3

[0049] 1) Preparation of nano-twinned nickel with extremely small twinned layer thickness by electrolytic deposition

[0050] Electrodeposition equipment: DC power supply

[0051] Electrolyte solution formula: 350g / L nickel sulfate hexahydrate, 50g / L nickel chloride hexahydrate, 50g / L boric acid; additives are sodium lauryl sulfate 0.1g / L, sodium saccharin 1.25g / L, 1,4 butyl Alkyne diol 0.64g / L, glacial acetic acid 0.07g / L; all the above reagents were dissolved in deionized water, stirred and dissolved, and then filtered through filter paper; adjust the pH value to 4.0 with 10% dilute sulfuric acid;

[0052] Cathode and anode requirements: the anode is a pure nickel plate with a purity of 99.6wt.%, and the cathode is a nickel substrate after surface degreasing and sensitization treatment.

[0053] 2) Electrolysis process parameters: DC current density is 50mA / cm 2 , the electrolyte temperature is 60±1°C, the area ratio of cathode and anode is 1:50, the distance between catho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com