Electromechanical actuator limiting stroke circumferential anti-blocking structure

A technology of electromechanical actuator and buckle structure, which is applied in mechanical equipment, transmission, belt/chain/gear, etc. The effect of simplifying the matching relationship of components, simplifying the matching relationship of components, and preventing radial deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

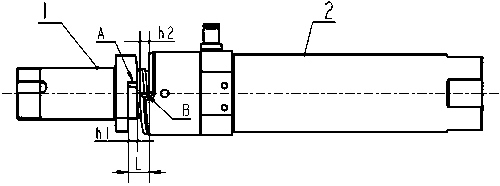

[0018] The working principle of the present invention is: as figure 1 As shown, the end face of the circumferential limit structure (position A, B) is attached to the contact end face between the ball screw 1 and the ball nut 2. By designing the length h1 and h2 of the protruding structure, the value is smaller than that of the ball screw pair lead Ph, so that the ball screw pair forms surface contact along the radial direction of the ball screw pair at the extreme position (L=0) and the effective contact area is the largest; at the same time, the circumferential limit end face (A, B position) design Along the radial direction of the ball screw pair, the force-bearing surface is along the normal plane of the circumferential tangent during contact, and there is no effective component force in the radial and axial directions of the ball screw pair, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com