Travel reducer test system

A technology of walking reducer and test system, which is applied in the direction of machine gear/transmission mechanism testing, thermometer parts, measuring devices, etc. It can solve the problems of low efficiency, large cost investment, and large space occupation, so as to reduce energy consumption, The effect of easy operation and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

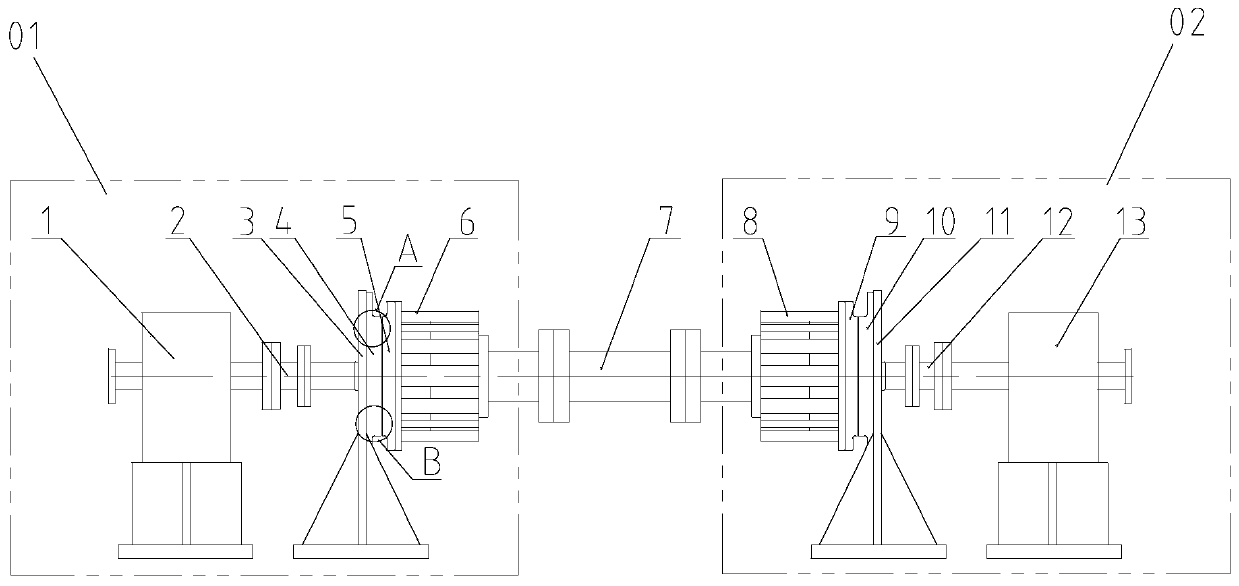

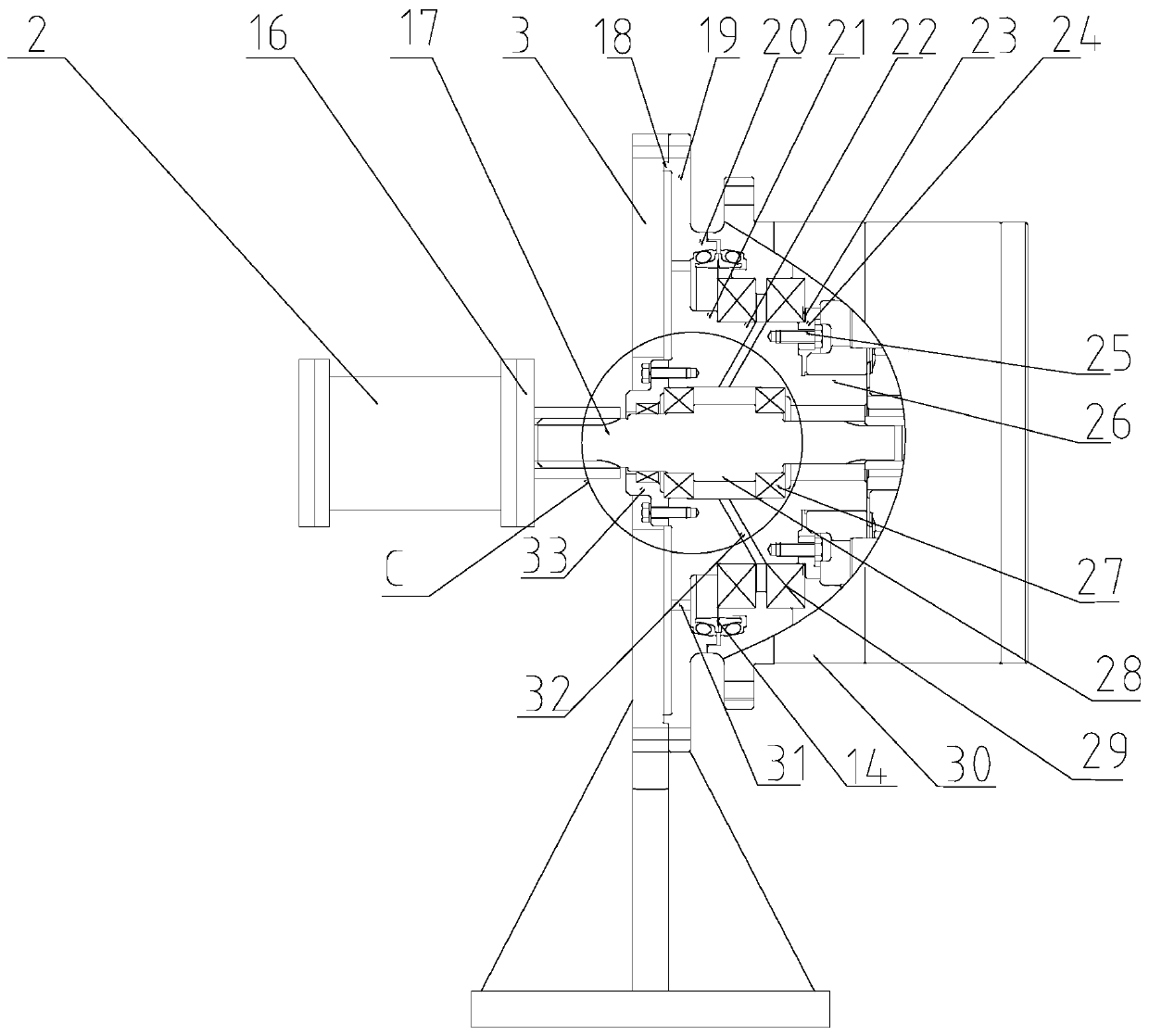

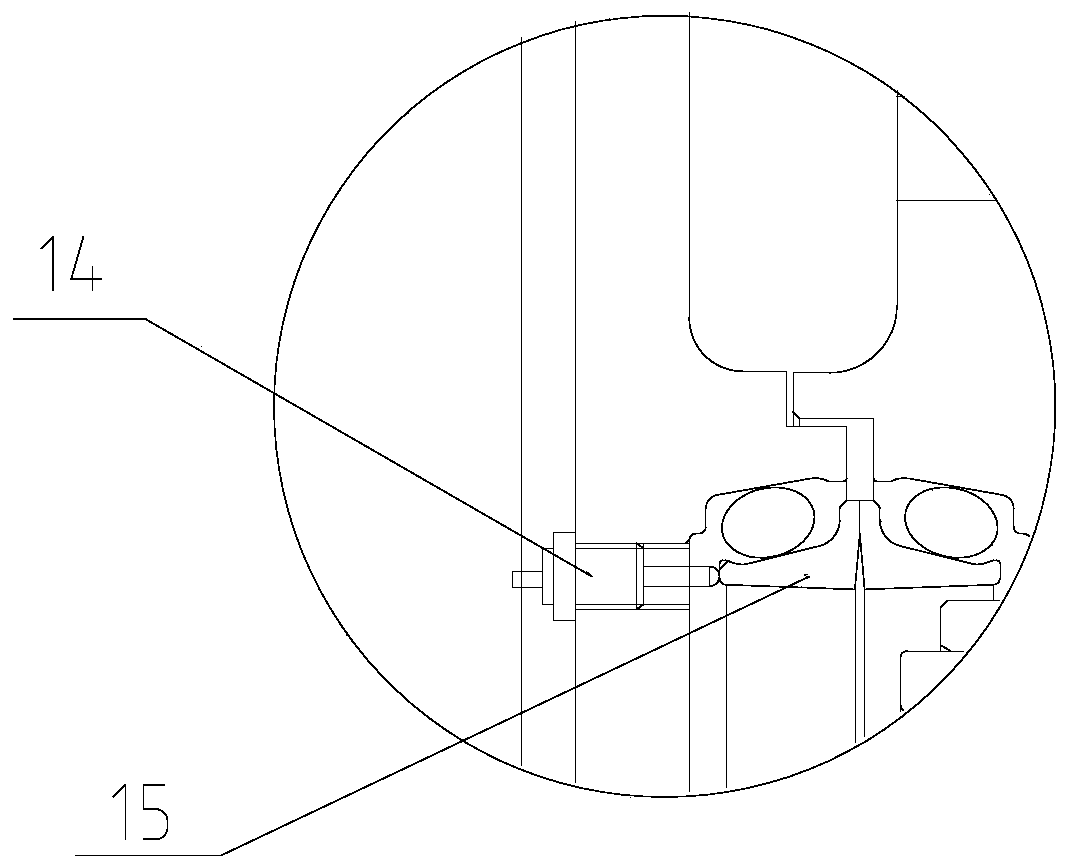

[0029] Such as Figure 1-Figure 5 As shown, the walking speed reducer test system of the present invention includes a test platform (not shown in the figure), a third coupling 7, a main test unit 01 and an accompanying test unit 02; the main test unit 01 and the accompanying test unit 02 pass The third shaft coupling 7 is arranged in a mirror image.

[0030] Among them, the main test unit 01 includes the loading motor 1, the first coupling 2, the first loading tool 4, the main travel reducer 5 to be tested, the first transition connection plate 6, and the first test bench 3; the accompanying test unit 02 It includes a load motor 13, a second coupling 12, a second loading tool 10, a travel reducer 9 to be tested, a second transition connection plate 8, and a second test bench 11;

[0031]The components of the main test unit 01 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com