Glass breaking device

A crushing device and glass technology, applied in grain processing, etc., can solve the problems of hidden safety hazards, low utilization rate, high cost, etc., and achieve the effects of prolonging service life, good use effect and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

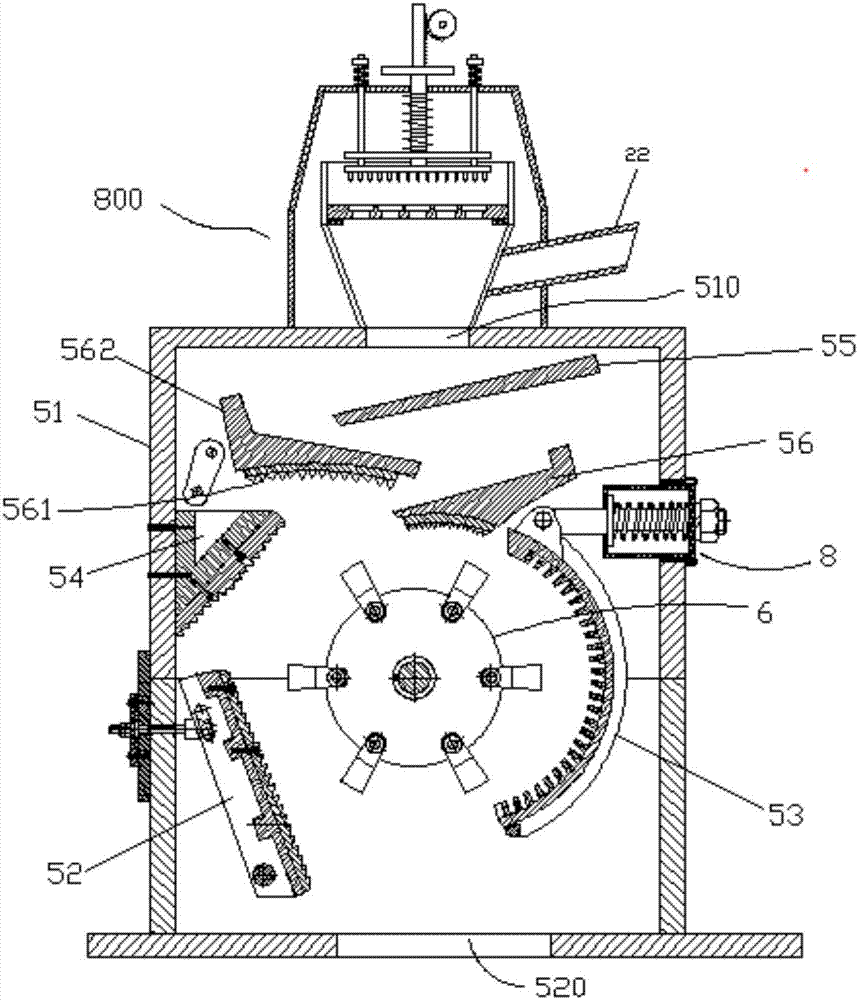

[0030] Such as figure 1 As shown, the present invention discloses a crushing device for crushing glass, which includes a crushing shell 51, on which is provided a feed port 510 and a discharge port 520, and also includes a bar-shaped counterattack plate 52, an arc counterattack Plate 53, counterattack block 54, first material guide baffle 55, second material guide baffle 56, rotor 6 and crushing mechanism 800, rotor 6 is rotatably connected in crushing shell 51, strip counterattack plate 52 and counterattack block 54 It is arranged on the left side of the rotor 6, and the counter-attack block 54 is located at the upper end of the strip-shaped counter-attack plate 52, and the arc-shaped counter-attack plate 53 is located on the right side of the rotor 6, a first material guide baffle 55 and two second material guide baffles 56 are layered from top to bottom below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com