Fixing roller

A technology of fixing rollers and porous materials, applied in the field of fixing rollers, can solve the problems of deterioration of durability of fixing rollers, uneven unit size, uncertain unit shapes, etc., and achieves the effects of improving reliability, preventing cracks, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0090] In Invention Example 1, liquid silicone rubber (trade name: KE-1353) produced by Shin-Etsu Chemical Co., Ltd. was used as the liquid silicone rubber material. In this liquid silicone rubber, polysiloxane containing active hydrogen (viscosity: 16Pa·S) and polysiloxane containing vinyl (viscosity: 15Pa·S) are provided in separate packages, and polysiloxane containing vinyl The oxane has a catalytic amount of platinum catalyst added thereto. Hereinafter, the former and the latter are referred to as "silicone rubber agent A" and "silicone rubber agent B", respectively. The polysiloxane containing active hydrogen has the chemical structure of formula (2), where each R 4 For methyl. Vinyl-containing polysiloxane has a chemical structure of formula (1), where each R 1 for vinyl, each R 2 For methyl. In addition, KF-618 (HLB: 11; hereinafter referred to as "dispersion stabilizer I") and KF-6015 (HLB: 4; hereinafter referred to as "dispersion stabilizer II") were used as di...

example 2

[0095] In Invention Example 2, liquid silicone rubber (trade name: DY35-7002) produced by Toray Dow Corning Co., Ltd. was used as the liquid silicone rubber material. In this liquid silicone rubber, active hydrogen-containing polysiloxane (viscosity: 15Pa·S) and vinyl-containing polysiloxane (viscosity: 7.5Pa·S) are provided in separate packages, and vinyl-containing polysiloxane The siloxane has a catalytic amount of platinum catalyst added thereto. Hereinafter, the former and the latter are referred to as "silicone rubber agent A" and "silicone rubber agent B", respectively. The polysiloxane containing active hydrogen has the chemical structure of formula (2), where each R 4 For methyl. Vinyl-containing polysiloxane has a chemical structure of formula (1), where each R 1 for vinyl, each R 2 For methyl. In addition, the aforementioned dispersion stabilizer I and dispersion stabilizer II were used as the dispersion stabilizer. The silicone elastomer itself obtained from ...

example 3

[0100] In Inventive Example 3, the compositions A and B used in Inventive Example 3 were mixed together. The obtained composition was stirred by means of a hand mixer for 3 minutes, while adding 10 parts by weight of water, and stirred for a further 2 minutes. The obtained composition was stirred with a hand mixer while gradually adding 90 parts by weight of water to obtain an emulsifier.

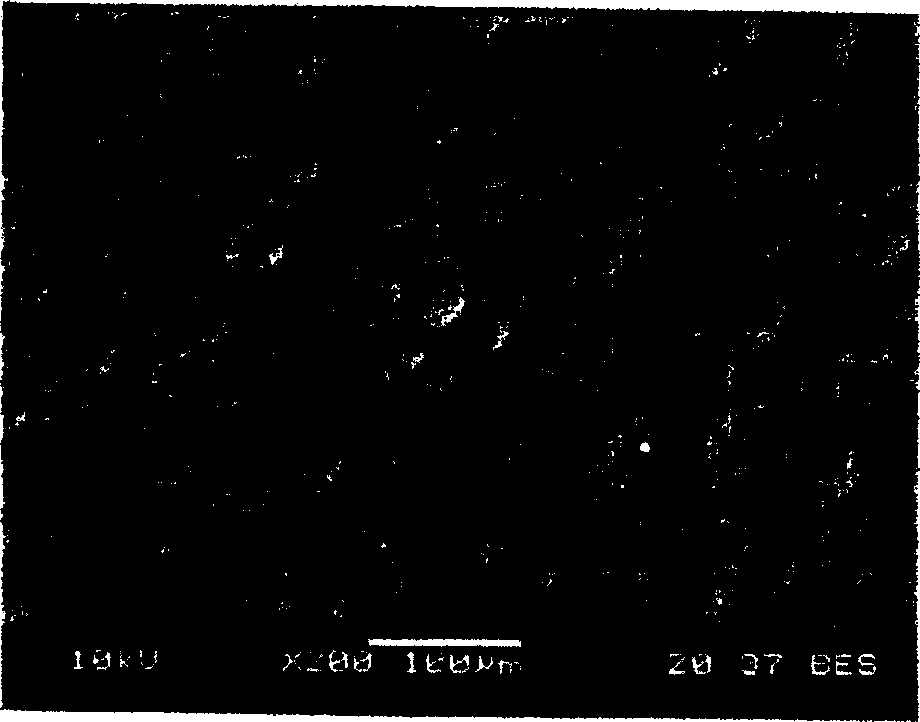

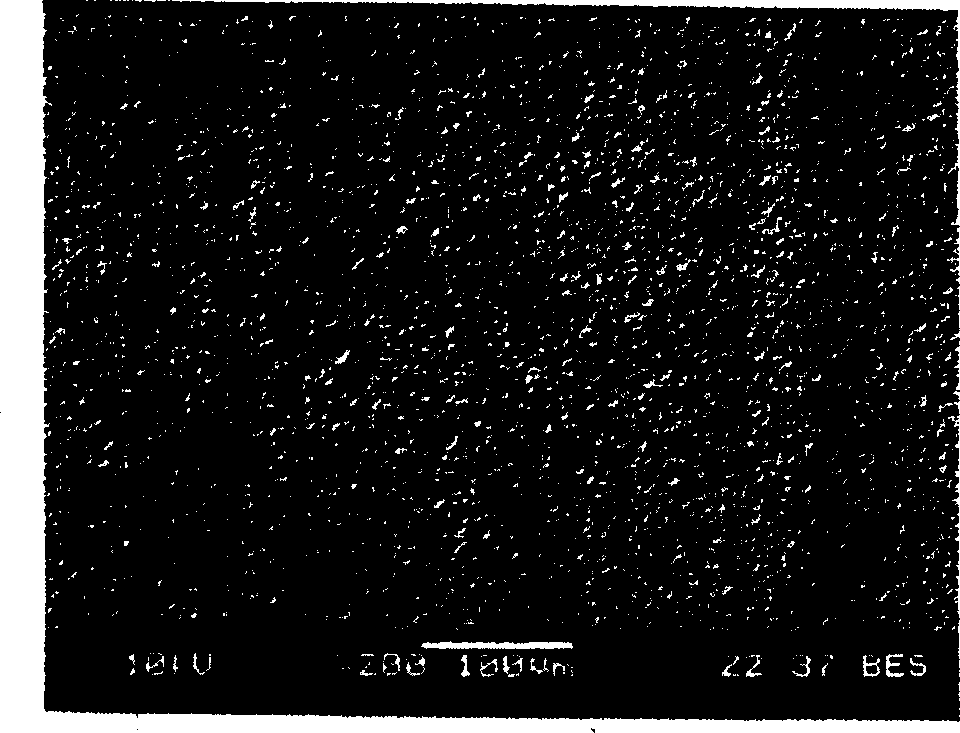

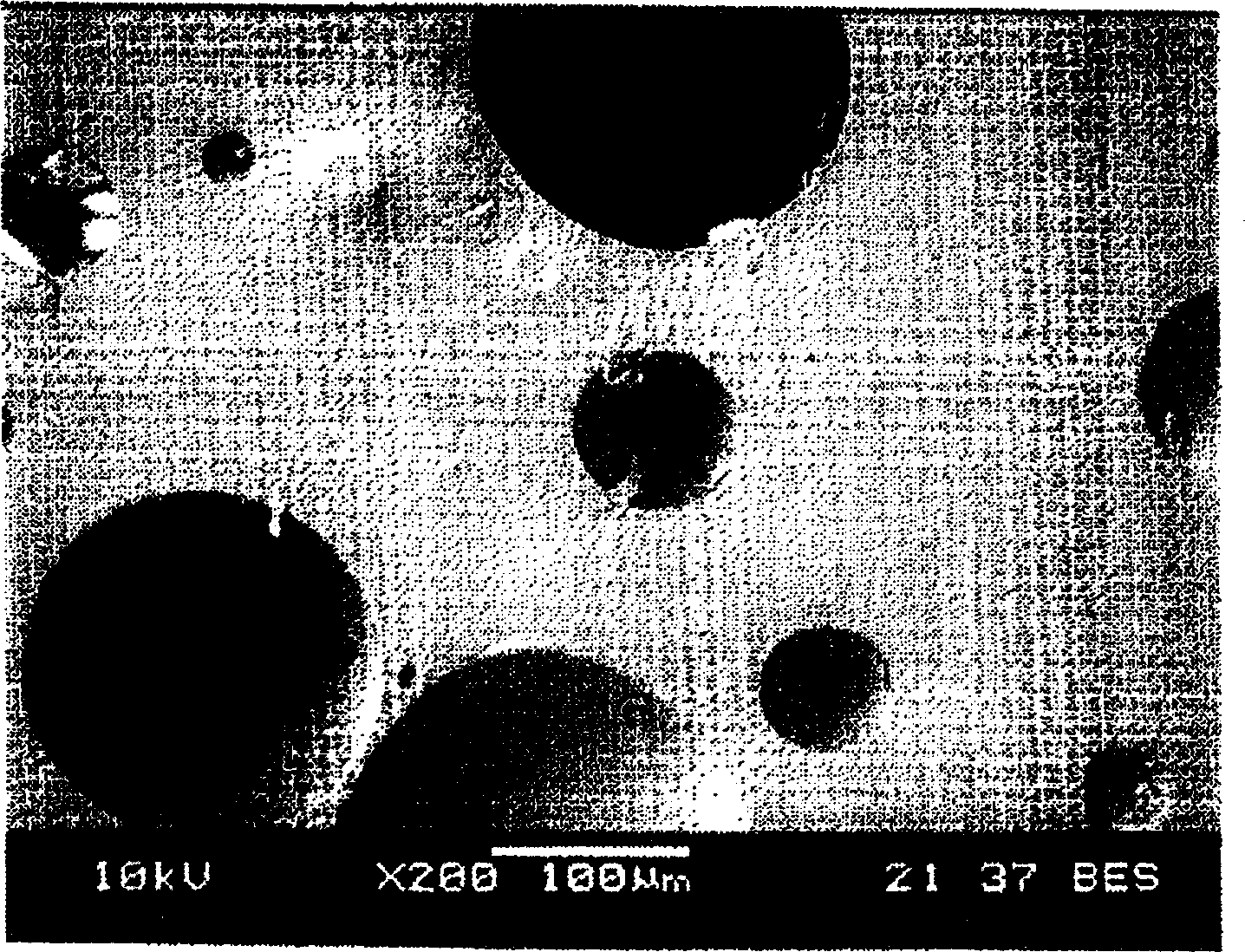

[0101]The obtained emulsifier was used in the same manner as Inventive Example 1 to prepare a silicon elastomer porous material test piece, and the cell size was measured to determine the closed cell ratio. The results are shown in Table 1 below. As shown by the test results, the specific gravity of the porous elastomer obtained in Invention Example 1 was 0.53, and the hardness (Asher-C) was 58. figure 2 A SEM photograph of the cut surface of the test piece is shown (magnification: ×100). In this way, a closed cell porous material with very fine / uniform cell size is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com