Automobile circular shaft part clamping tool

A part clamp and round shaft technology, which is applied in the field of auxiliary equipment for the production of auto parts, can solve the problems of axial offset and deflection of round shaft parts, and achieve the effects of improving firmness, convenient unloading, and increasing clamping firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

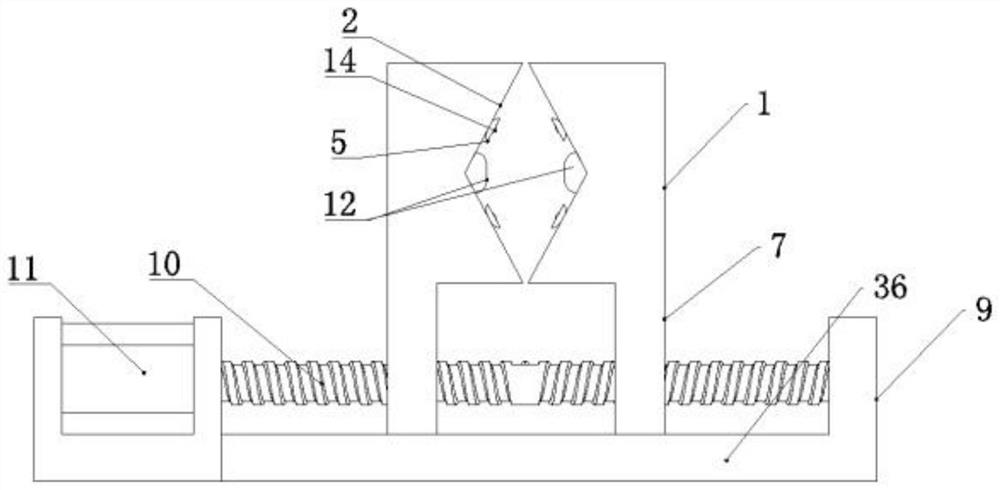

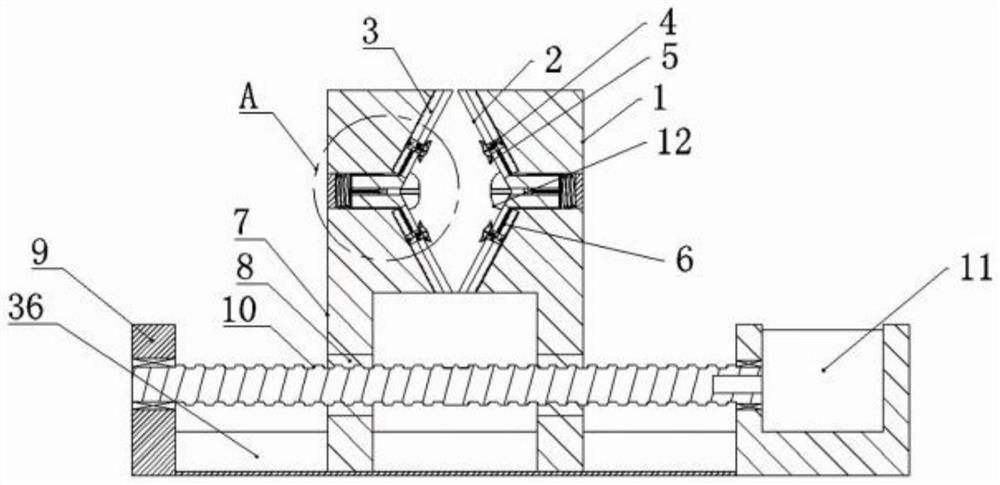

[0037] Car round shaft part clamping tool, reference Figure 1 - Figure 5As shown, including two-to-one or away from the V-shaped block 1, the two V-shaped block 1 is adjacent or away from or away from the one-to-one side of the two V-shaped block 1 extends two and one guide 36. The blending block 7, the two mating block 7 end is convex with the slider 4 in which the guide rail 36 is embedded in the guide slip, the cross section of the slider 4 and the guide rail 36 guide is "dove tail" or "inverted T shape" A nut 8 opposite to the threaded direction is fixed to the two-fitting block 7, and two housing 9 is fixed at both ends of the guide rail 36, and the rotation between the bearing housing 9 is provided with the reverse screw 10 that cooperates with the two screw 8, reverse direction. The rotation of the screw 10 is controlled by a motor 11 fixed to the guide rail 36, since the two screw portions are in opposite to the reverse wire rod 10, as the motor 11 is rotated, the two scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com