Polymer thin sheet, and manufacturing method and application thereof

A polymer and sheet technology, used in applications, chemical instruments and methods, household components, etc., can solve the problems of large compression set, difficult to ultra-thin, unfavorable packaging and processing, etc., and achieve low compression set. Quantitative, good low-density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

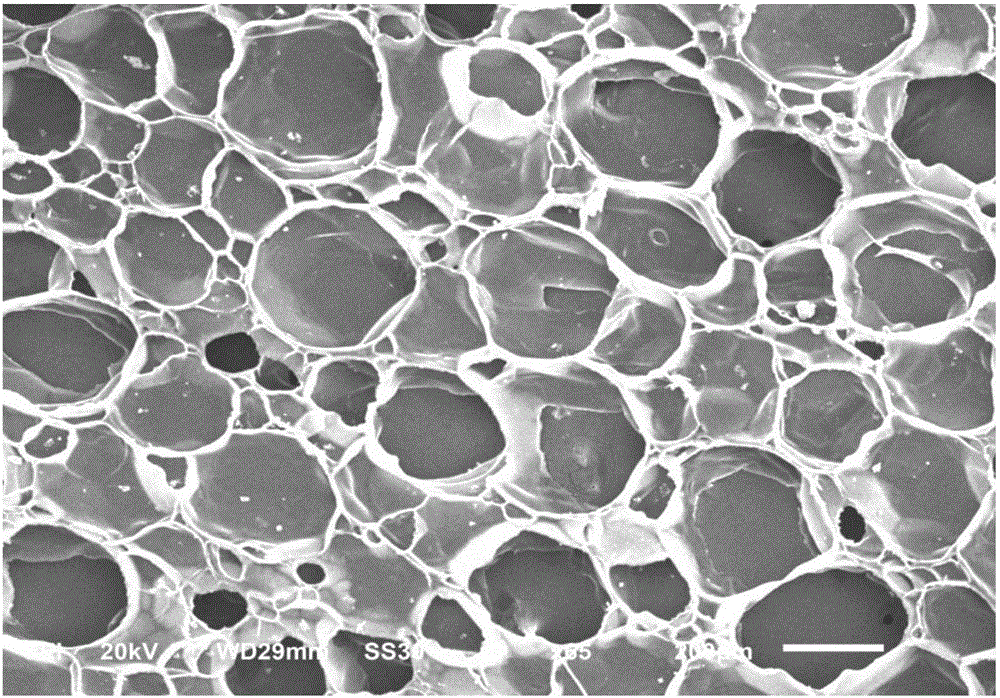

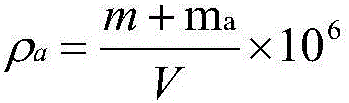

[0068] Select a commercially available rigid polyurethane foam substrate with a thickness of 5 mm, a width of 500 mm, a length of 800 m, an average pore diameter of 500 μm, and an apparent density of 0.7 g / cm 3 , The compression ratio is 30%, its 70 ℃ compression set ≤ 50% (75% compression, 22h), 23 ℃ compression set ≤ 30%, hardness (Shore D) 50 degrees.

[0069] Step 5: Cut the first layer of the rigid polyurethane foam substrate, place the raw material of the rigid polyurethane foam substrate on the unwinding device, start the knife belt type skin cutting machine, the winding device, and the unwinding device,

[0070] Unwinding step: send the rigid polyurethane foam substrate to the cutting device, the feeding speed is 0.1m / min, the thickness of the rigid polyurethane foam substrate is 5mm,

[0071] Continuous cutting step: according to the average pore diameter of the polymer raw material, the cross-section perpendicular to the thickness direction of the polymer coil is cut...

Embodiment 2

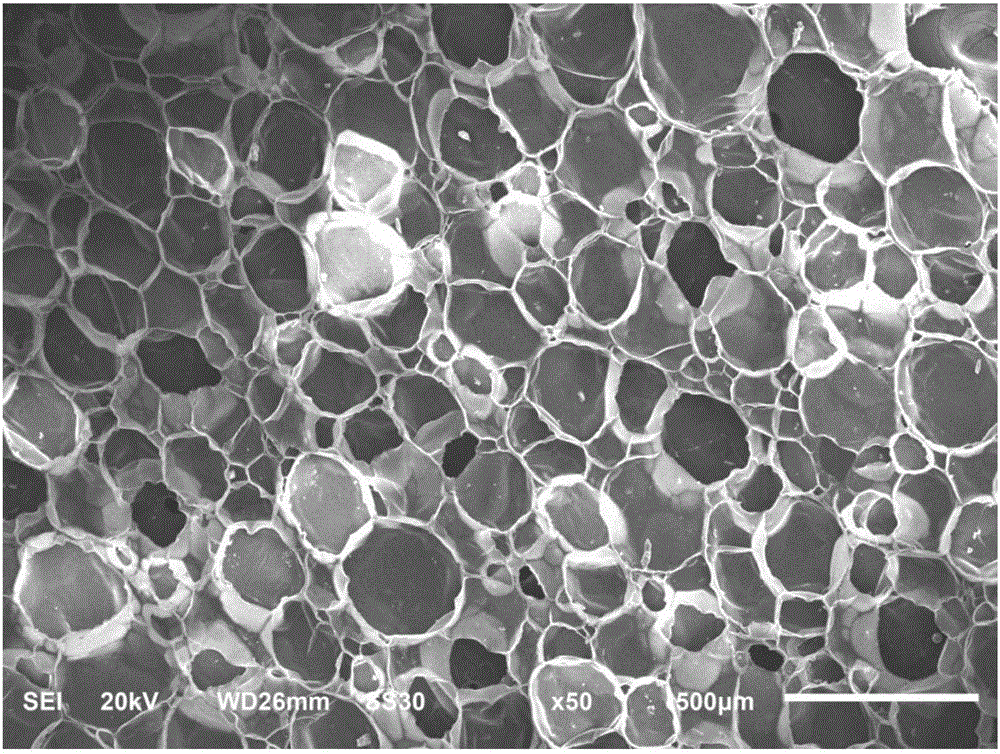

[0078] Select a commercially available foam substrate made of natural rubber and butyl rubber, the thickness of the substrate is 3 mm, the width is 800 mm, the length is 800 m, the pore diameter range is 40 μm to 400 μm, the average pore diameter is 300 μm, and the apparent density is 0.5 g / cm 3 , The compression ratio is 40%, its 70 ℃ compression set ≤ 40% (75% compression, 22h), 23 ℃ compression set ≤ 35%, the hardness is (Shore C) 45 degrees.

[0079] Cutting of the first layer of the substrate: place the substrate raw material on the unwinding device, start the knife belt type skin cutting machine, the winding device, and the unwinding device,

[0080] Unwinding step: feed the polymer coil with the same material as the polymer sheet into the cutting device, the feeding speed is 10m / min, the thickness of the polymer coil is 3mm,

[0081] In the continuous cutting step, according to the average pore diameter of the polymer raw material, the polymer coil is cut into polymer s...

Embodiment 3

[0088] Select a commercially available foaming coil with polycarbonate as the main component, the thickness of the coil is 0.1mm, the width is 1500mm, the length is 1000m, the average pore diameter is 10μm, and the apparent density is 0.04g / cm 3 , The compression ratio is 60%, the compression set at 70°C is ≤30% (75% compression, 22h), the compression set at 23°C is ≤20%, and the hardness is (Shore C) 10 degrees.

[0089] Step 3: Cut the first layer of polycarbonate coil, place the polycarbonate coil on the unwinding device, start the hot wire cutting machine, winding device, unwinding device,

[0090] Unwinding step: feed the polymer coil with the same material as the polymer sheet into the cutting device, the feeding speed is 5m / min, the thickness of the polymer coil is 0.1mm,

[0091] Continuous cutting step: according to the average pore diameter of the polymer raw material, the polymer sheet is thinned into a polymer sheet with a set thickness along the cross-section of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com