Packaging machine film releasing method

A packaging machine and packaging film technology, applied in packaging, transport packaging, transportation and packaging, etc., can solve the problems of affecting the efficiency and quality of film release, time-consuming and labor-intensive replacement of packaging film, and inconvenient wearing of packaging film, so as to improve release Membrane efficiency, guaranteed continuity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The film release method of the packaging machine includes the following steps:

[0048] a. Place the reel packaging film on the film release equipment of the packaging machine, then pull a part of the reel packaging film through the film passing roller 1 on the film release equipment of the packaging machine and connect with the film pulling equipment of the next process;

[0049] b. Then press the active rubberized wheel 11 on the film releasing equipment of the packaging machine on the reel packaging film;

[0050] c. Rotate the active rubber coating wheel 11, and the active rubber coating wheel 11 applies a tangential force to the roll packaging film to release the packaging film.

[0051] This embodiment is the most basic implementation mode. a. Place the reel packaging film on the film release equipment of the packaging machine, and then pull out a part of the reel packaging film to pass through the film roller on the film release equipment of the packaging machine...

Embodiment 2

[0053] The film release method of the packaging machine includes the following steps:

[0054] a. Place the reel packaging film on the film release equipment of the packaging machine, then pull a part of the reel packaging film through the film passing roller 1 on the film release equipment of the packaging machine and connect with the film pulling equipment of the next process;

[0055] b. Then press the active rubberized wheel 11 on the film releasing equipment of the packaging machine on the reel packaging film;

[0056] c. Rotate the active rubber coating wheel 11, and the active rubber coating wheel 11 applies a tangential force to the roll packaging film to release the packaging film.

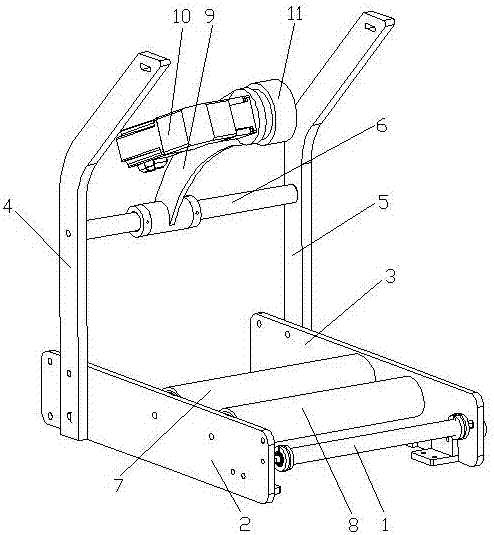

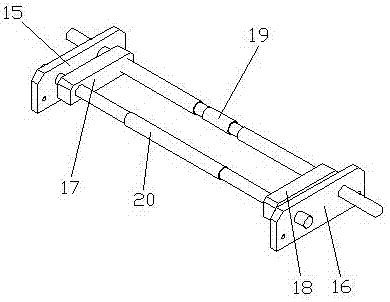

[0057] The film release equipment of the packaging machine includes a support and a film passing roller 1. The support includes a first seat plate 2, a second seat plate 3, a first support plate 4, a second support plate 5 and a connection between the first support plate 4 and the The fu...

Embodiment 3

[0060] The film release method of the packaging machine includes the following steps:

[0061] a. Place the reel packaging film on the film release equipment of the packaging machine, then pull a part of the reel packaging film through the film passing roller 1 on the film release equipment of the packaging machine and connect with the film pulling equipment of the next process;

[0062] b. Then press the active rubberized wheel 11 on the film releasing equipment of the packaging machine on the reel packaging film;

[0063] c. Rotate the active rubber coating wheel 11, and the active rubber coating wheel 11 applies a tangential force to the roll packaging film to release the packaging film.

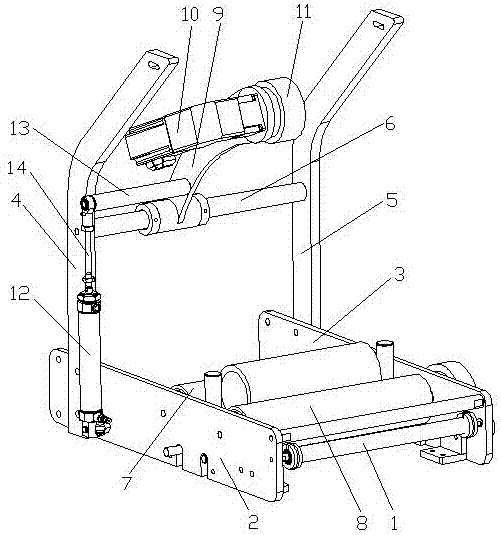

[0064] The film release equipment of the packaging machine includes a support and a film passing roller 1. The support includes a first seat plate 2, a second seat plate 3, a first support plate 4, a second support plate 5 and a connection between the first support plate 4 and the The fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com