Fabricated subway station platform and construction method thereof

A subway station, prefabricated technology, applied in the direction of stations, railway car body parts, transportation and packaging, etc., to achieve the effect of facilitating factory production, facilitating length and shortening, and improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

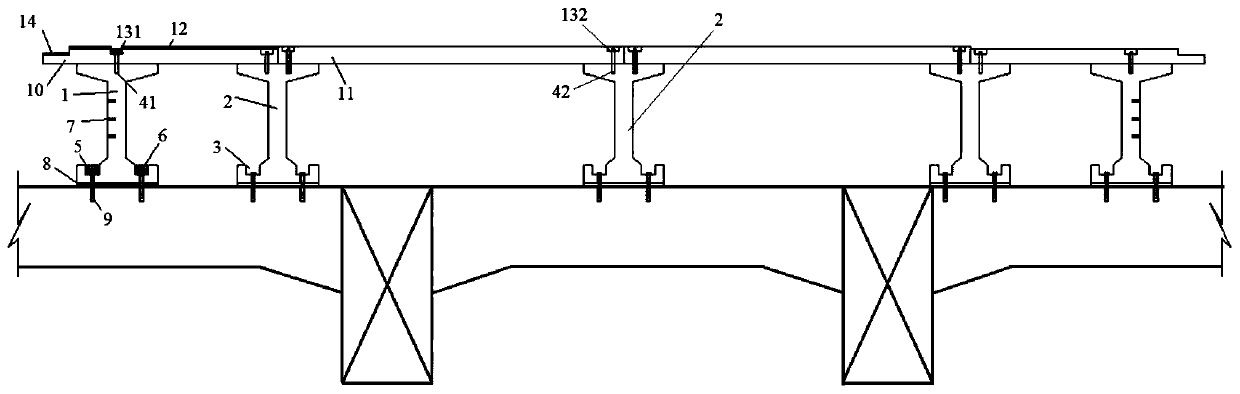

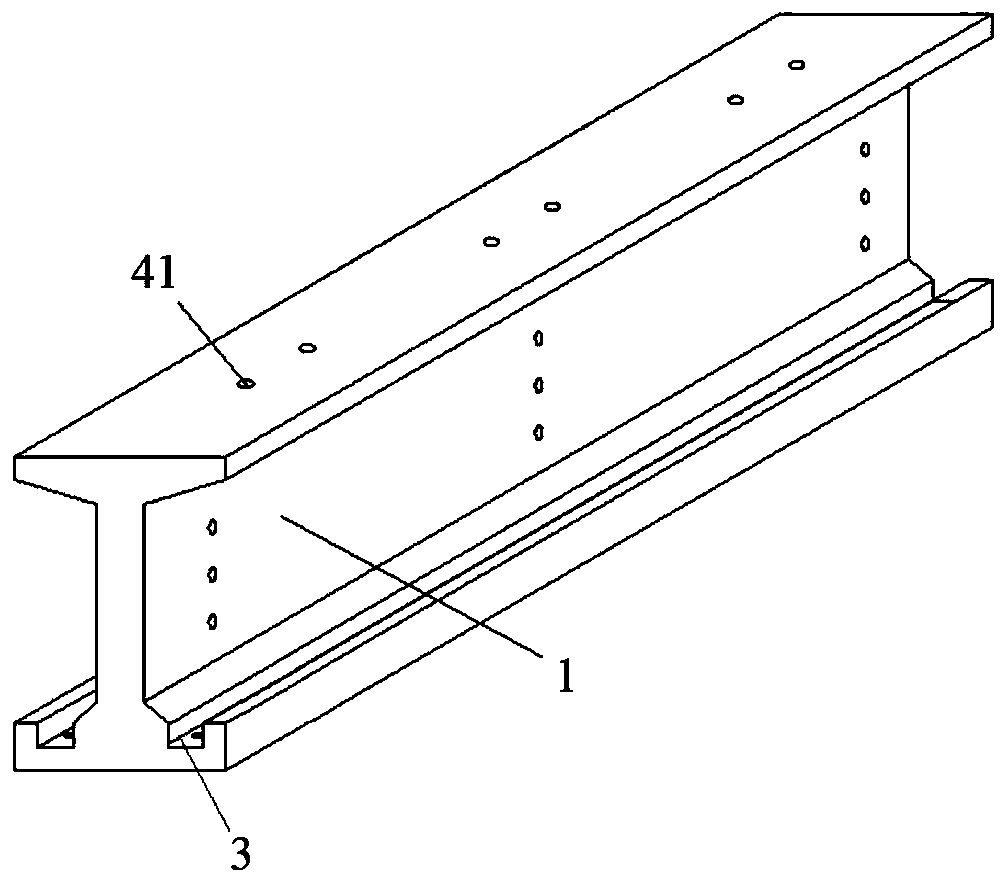

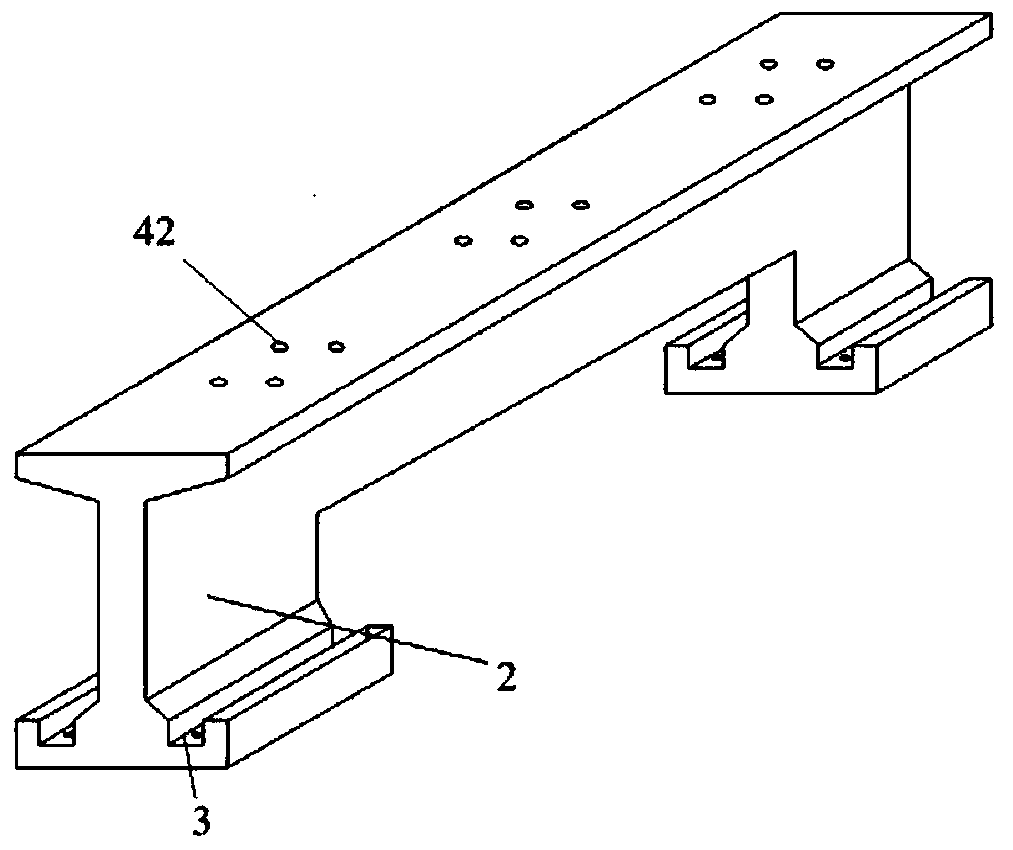

[0033] like Figure 1-7 As shown, the prefabricated subway station platform of this embodiment includes side joists 1, middle joists 2, side platform slabs 10, and middle platform slabs 11; after prefabricated side joists 1 and prefabricated middle joists 2, all Fixed on the ground by expansion bolts 9, the side platform board 10 and the middle platform board 11 are respectively fixed on the corresponding side joists or middle joists through on-site drilling and planting bars.

[0034] As preferably, the side joist 1 of the present embodiment is an I-shaped structure (full I-shaped), and the mold is opened according to the size of the side joist 1 in the factory, and the abdomen at the two ends of the side joist 1 is provided with Nut 7 is embedded in the cable bracket, expansion bolt installation holes 5 and waterproof grooves 3 are reserved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com