Vehicle shelf

A technology for racks and vehicles, applied in the field of auxiliary transportation devices, can solve the problems such as the inability to adjust the position of the pull rope fixing buckle, the inconvenience of adjusting the length and width of the vehicle rack, and the uneven top of the beam, so as to achieve convenient width and stable cargo binding. , The effect of bundling the goods is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

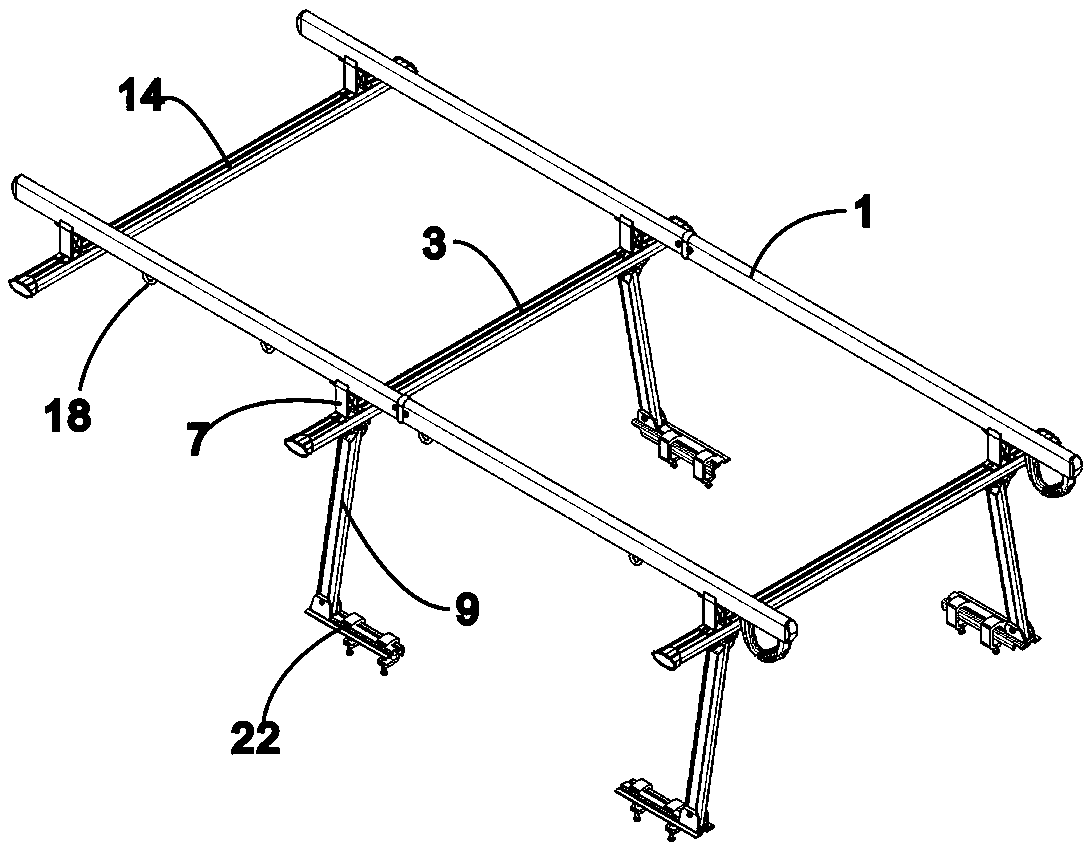

[0036] Please refer to figure 1 , the vehicle shelf provided in this embodiment includes a crossbeam 1, a fixed rod 3, a mobile frame 14, a support frame 9, a fixed seat 22, a pull cord fixing buckle 18 and a connecting seat 7, wherein the crossbeam 1 and the fixed rod 3 are two , the two beams 1 are relatively placed, and at the same time, the two fixed rods 3 are arranged at the bottom of the two beams 1 to form a cross with the beam 1. The above-mentioned connecting seat 7 is used to connect the beam 1 and the fixed rod 3, and each fixed rod 3 The bottom of each is also fixed with two bracing frames 9, and the bottom of bracing frame 9 is fixed with holder 22, and above-mentioned mobile frame 14 is fixed with two beams 1, and can move back and forth along beams 1.

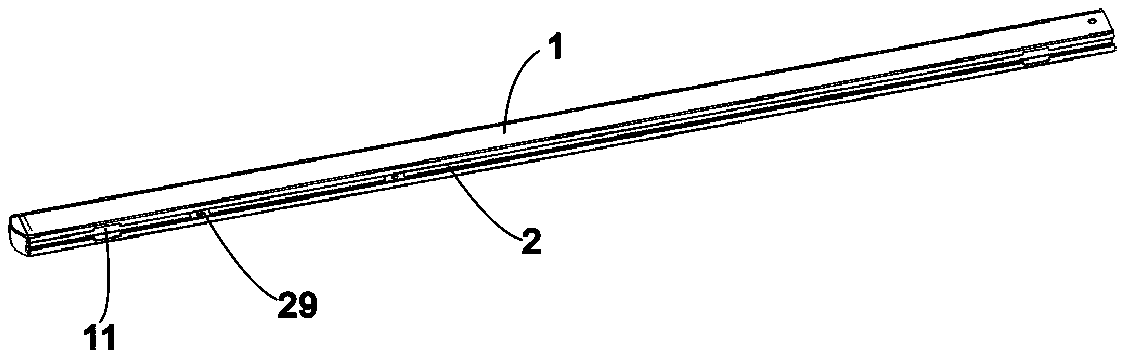

[0037] refer to figure 2 The above-mentioned crossbeam 1 is a square aluminum alloy hollow rod, and its front side end surface, that is, the center of the lower bottom surface during use, has a chute 2 along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com