Printed circuit board (PCB) transmission system of selective crest welder capable of steadily transmitting

A technology of wave soldering machine and transmission system, applied in the field of PCB transmission system, can solve the problems of small adjustment range, inability to meet production requirements, large shaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

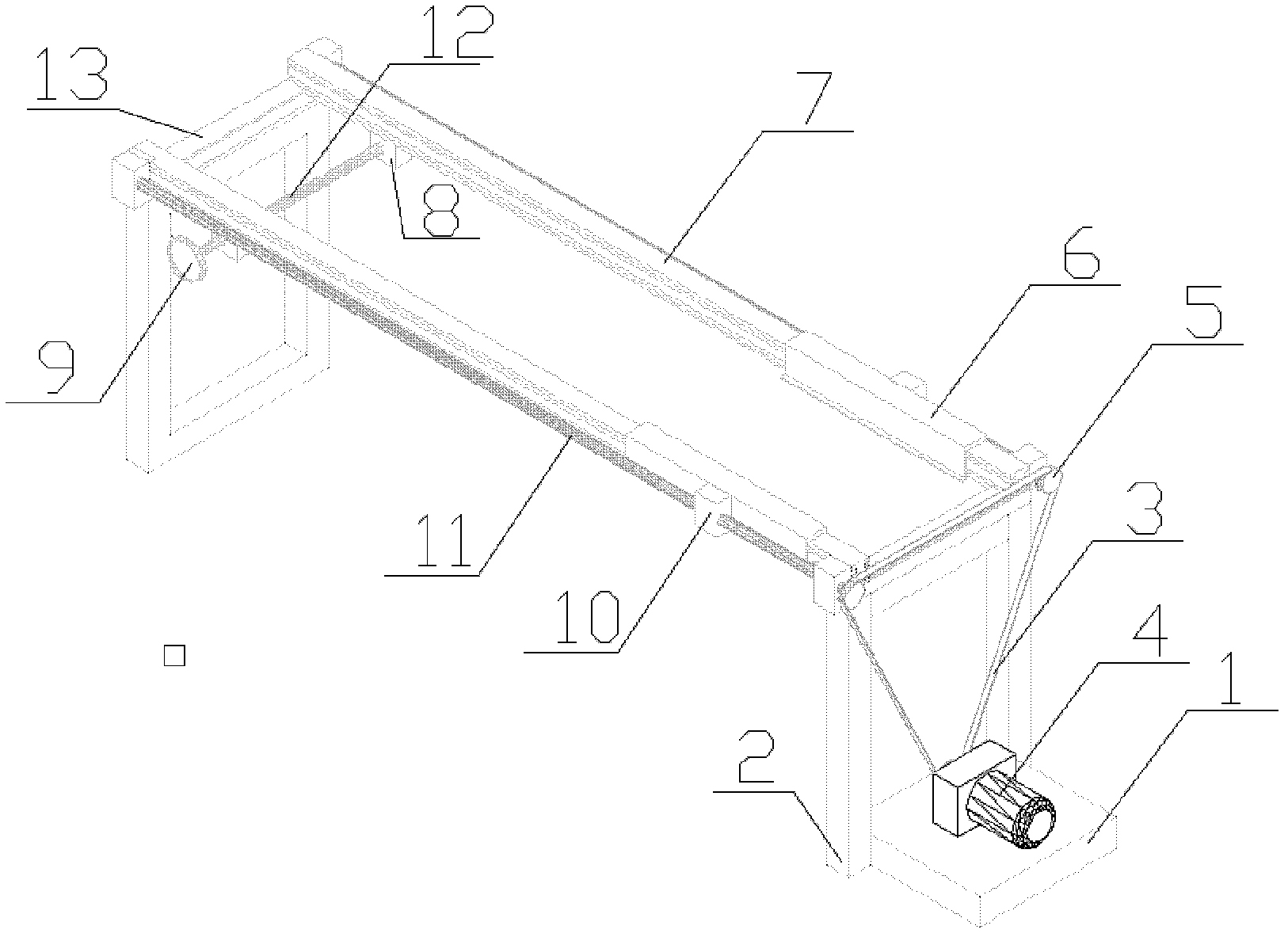

[0009] The structural principle and working principle of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0010] As shown in the drawings, the PCB transmission system of a selective wave soldering machine with stable transmission in the present invention includes a base 1, a motor 4 fixed on the base 1 and a bracket 2, and a pair of parallel sliding guide rails fixed on the bracket 2 13. A pair of transmission guide rails 7 are respectively installed on a pair of sliding guide rails 13 through the two ends of the sliding grooves. One end of a pair of transmission guide rails 7 is fixed on the sliding guide rails 13, and the other end can slide on the sliding guide rails 13. The transmission frame 6 is installed On the transmission guide rail 7, the outer ends of a pair of transmission guide rails 7 are respectively provided with transmission screw screws 11, and the two ends of a pair of transmission guide rails 11 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com