Light hard double-layer honeycomb polypropylene hollow plate

A double-layer honeycomb, polypropylene technology, applied in the direction of lamination, layered products, lamination devices, etc., can solve the problems of deformation under pressure, weak, poor impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

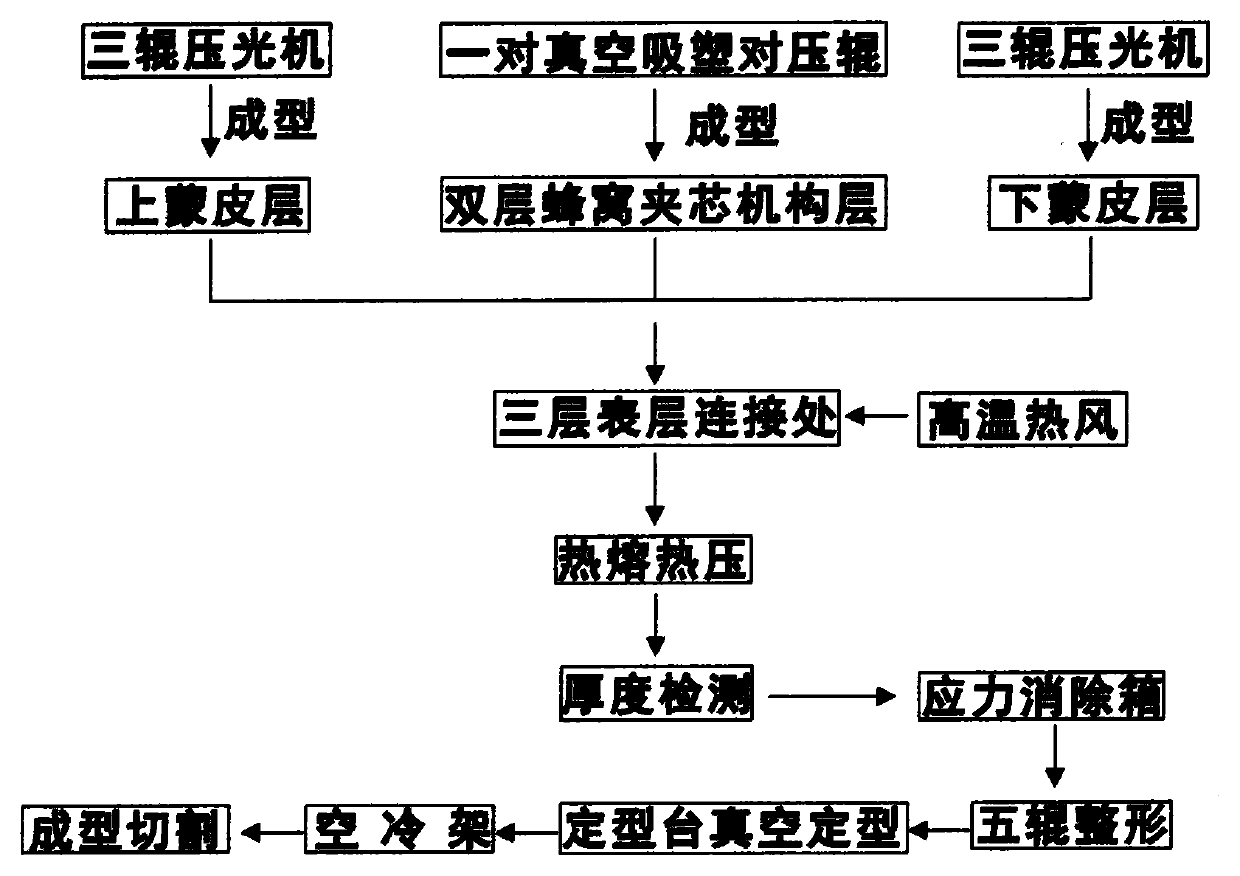

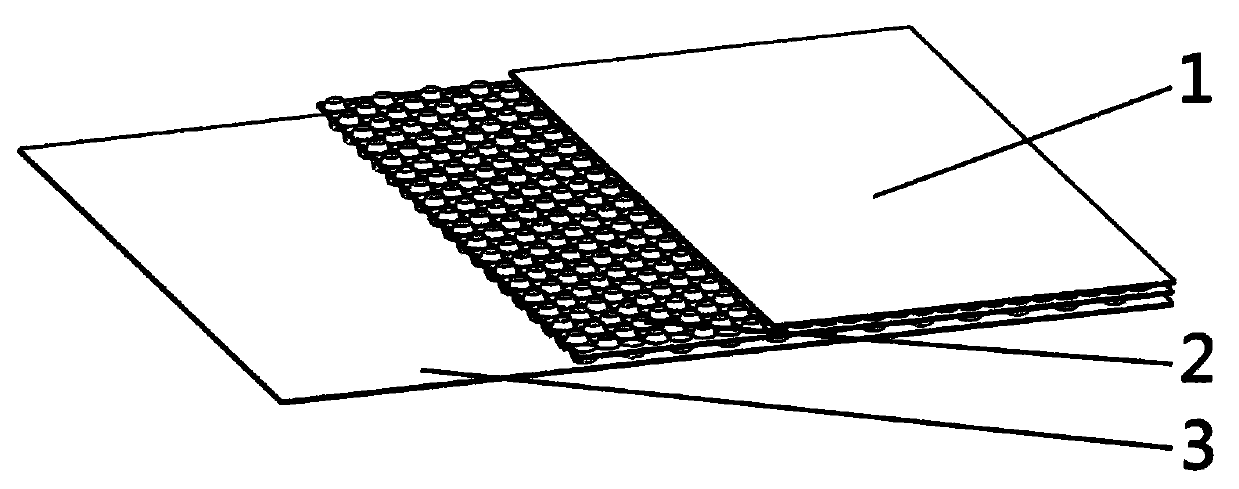

[0021] A hard and lightweight double-layer honeycomb polypropylene hollow board, its process flow and structure please refer to the attached figure 1 And attached figure 2 .

[0022] A hard and light double-layer honeycomb polypropylene hollow board, which belongs to the manufacturing method of multi-layer co-extruded hollow board, is characterized in that: the internal structure of the hard and light double-layer honeycomb polypropylene hollow board includes the above The skin layer, the double-layer honeycomb sandwich mechanism layer and the lower skin layer, the upper skin layer and the lower skin layer are extruded by a three-roll calender, and the double-layer honeycomb sandwich mechanism layer is extruded by a plastic extruder through a pair of vacuum Blister forming against pressure rollers, the double-layer honeycomb sandwich mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com