Processing method of silicon micro resonator

A technology of silicon microresonator and processing method, which is applied in the field of sensors to achieve the effect of high pressure resistance effect and stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

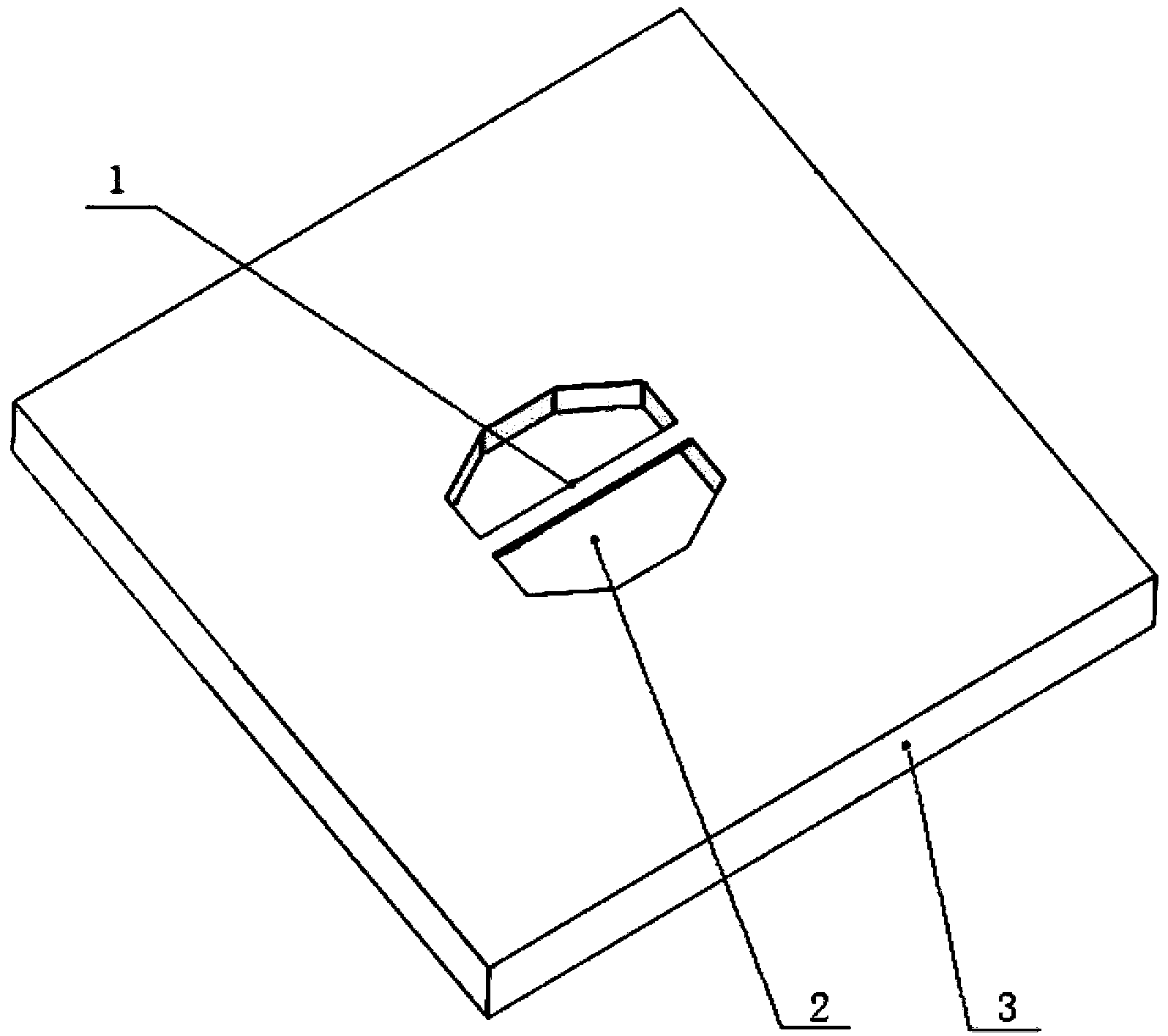

[0024] Specific implementation mode one: the following combination Figure 1 to Figure 8 Describe this embodiment mode, the processing method of silicon microresonator described in this embodiment mode, this method comprises the following steps:

[0025] Step 1. Select an N-type silicon wafer with a resistivity of 3Ω·cm~10Ω·cm as the silicon wafer to be processed, perform thermal oxidation treatment on the silicon wafer to be processed, form an oxide film on the upper and lower surfaces of the silicon wafer to be processed, and obtain Thermal oxidation treatment of silicon wafers;

[0026] Step 2: Etch the resonant beam structure pattern on the upper surface of the thermally oxidized silicon wafer by photolithography; then remove the oxide layer on both sides of the resonant beam by reactive ion etching process or wet etching process; The reactive ion etching process forms two deep grooves symmetrically on both sides of the resonant beam, and the depth of the deep grooves is...

specific Embodiment approach 2

[0035] Specific implementation mode two: this implementation mode further explains implementation mode one, and the process of etching the resonant beam structure pattern on the upper surface of the thermally oxidized silicon wafer by using the deep reactive ion etching process described in step two is:

[0036] Etching is carried out symmetrically on both sides of the structural pattern of the resonant beam to form two symmetrical deep grooves, the depth of the deep grooves is the thickness of the resonant beam, and the width of the interval between the two deep grooves is the width of the resonant beam.

[0037] The resonant beam is placed along the crystal direction, and the length of the resonant beam is its width more than double.

specific Embodiment approach 3

[0038] Embodiment 3: The manufacturing method of the resonator involved in this embodiment combines dry and wet etching processes of semiconductors, and utilizes the corrosion characteristics of silicon wafers. The resonator whose vibration frequency is 110kHz is taken as an example to illustrate its manufacturing method. The resonant beam is placed along the direction, with a thickness of 6 microns, a length and a width of 600 microns and 40 microns, respectively. It is located in a chamber with a depth of 20 microns. The length and width of the etched regions on both sides of the resonant beam are 600 microns and 200 microns, respectively.

[0039] The specific process steps are as follows:

[0040] (1) Use N-type silicon wafers with a resistivity of 3-10Ω·cm. thermal oxidation of silicon wafers (eg figure 2 , 3 shown);

[0041] (2) The pattern of the resonant beam structure is etched by deep reactive ion etching (DRIE). The resonant beams are arranged along the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com