Industrial washing machine washing internal cylinder with non-welded structure and manufacturing method thereof

A washing machine and inner drum technology, applied in the field of industrial washing machine washing inner drum, can solve the problems of low production efficiency, inability to effectively guarantee the overall quality of equipment, poor production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

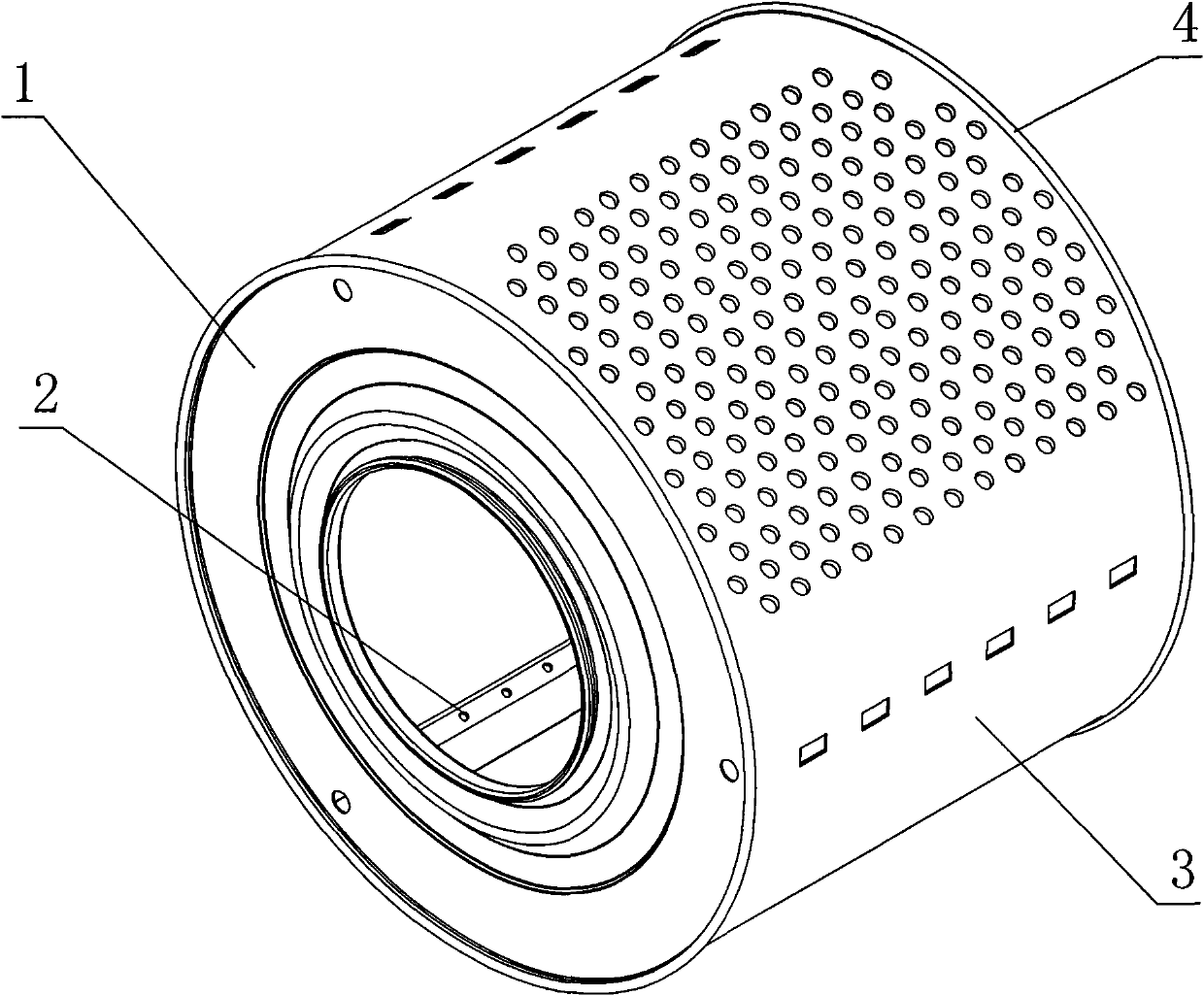

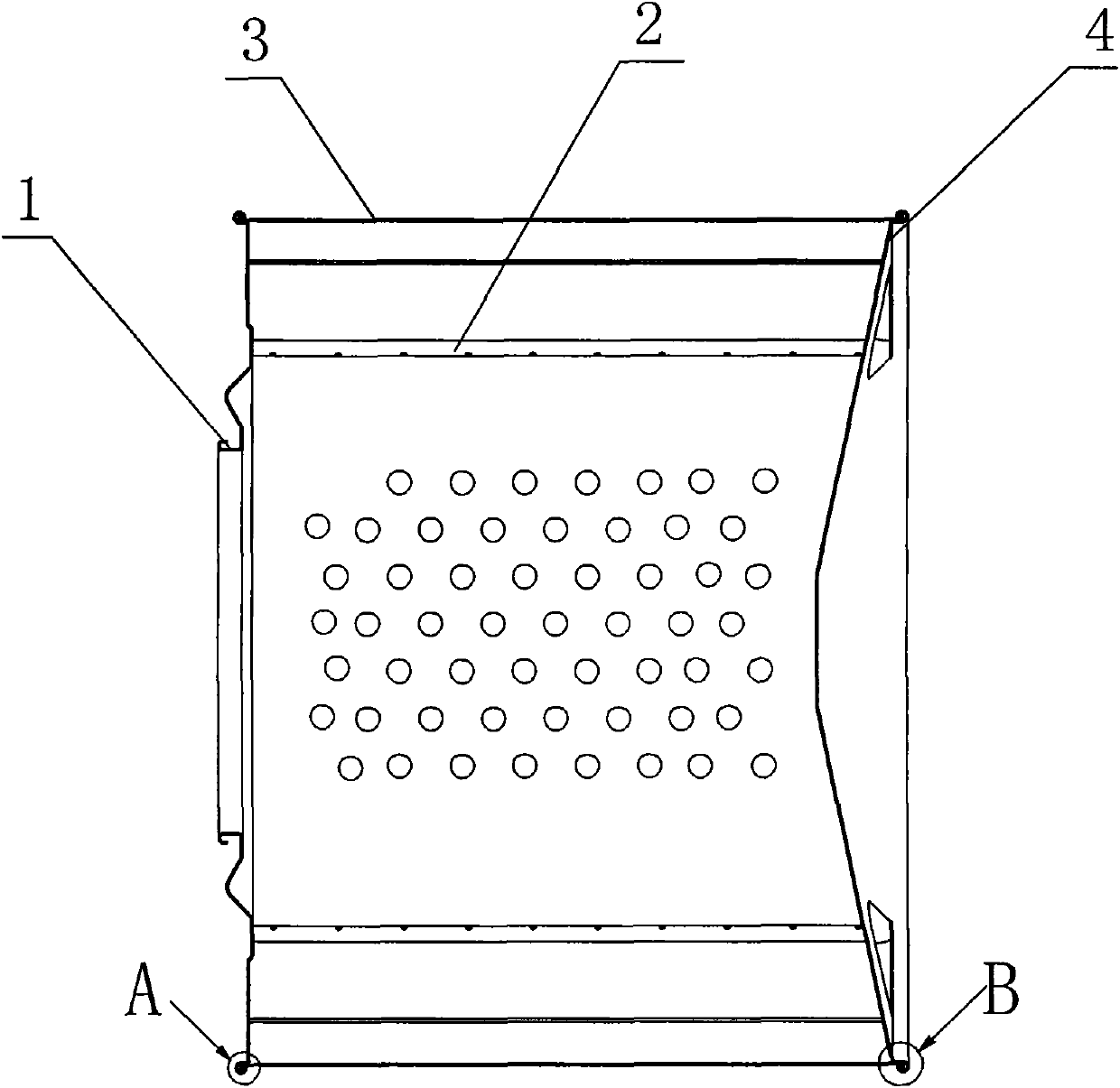

[0033] see figure 1 , 2 , the industrial washing machine laundry inner cylinder of the welding-free structure of the present invention, its components include a processed cylindrical mesh 3, a number of mesh holes are evenly distributed on the mesh 3, and the two ends of the cylindrical mesh 3 are fixedly connected with inner The front and rear end covers 1, 4 of the cylinder, and the inner wall of the mesh 3 are provided with several lifting ribs 2 at intervals;

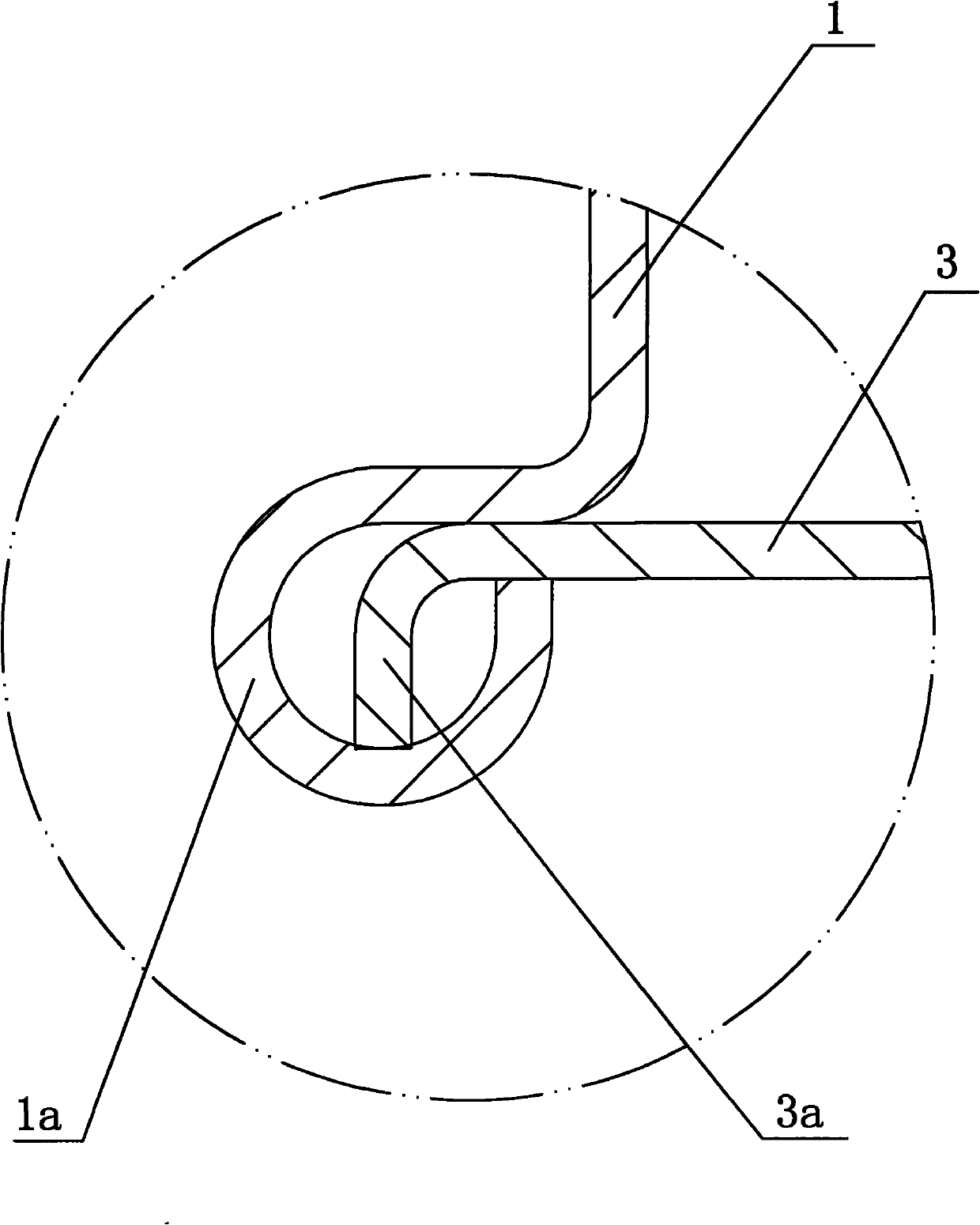

[0034] Such as image 3 , 4 As shown, the edges of the front and rear ends of the mesh 3 are provided with outwardly turned folds 3a; the edges of the front and rear end covers 1, 4 are provided with outwardly turned curls 1a, 4a;

[0035] Such as figure 2 As shown, the lifting rib 2 is closely attached to the inner wall of the mesh 3, and its two ends are tightly sandwiched between the front and rear end covers 1 and 4;

[0036] The crimps 1a, 4a on the front and rear end covers 1, 4 of the mesh 3 and the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com