Dimple-shaped honeycomb hollow plate and manufacturing method thereof

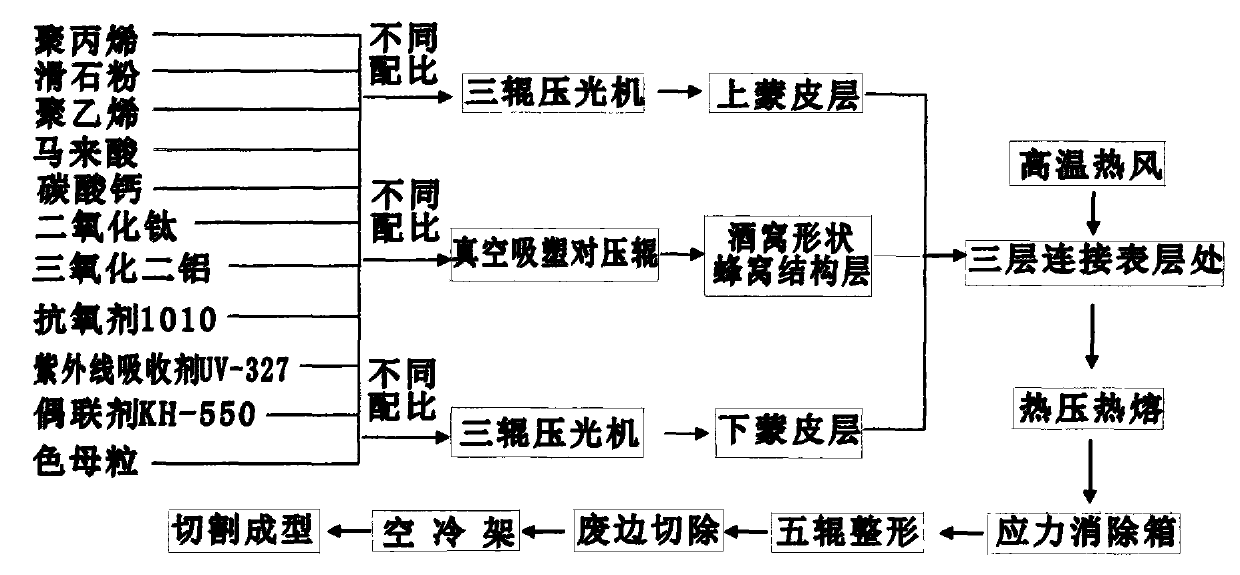

A manufacturing method and technology of dimples, which are applied in the field of dimple-shaped honeycomb hollow boards and their manufacture, and the manufacture of multi-layer co-extruded hollow boards, which can solve problems such as instability, poor impact resistance, and compression deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

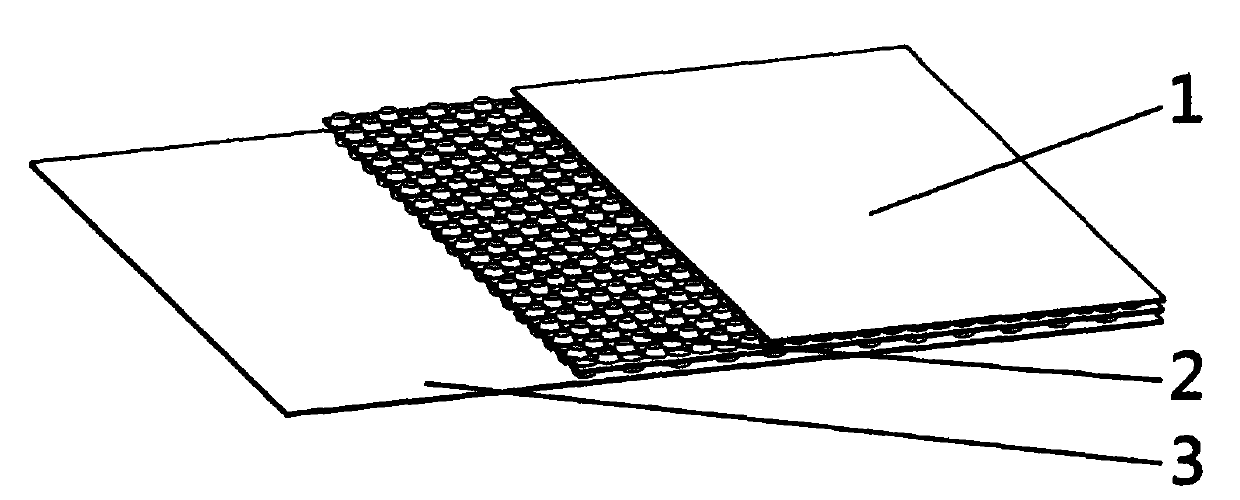

[0022] A dimple-shaped honeycomb hollow panel, characterized in that: the internal structure of the dimple-shaped honeycomb hollow panel includes an upper skin layer, a dimple-shaped honeycomb structure layer and a lower skin layer, and the dimple-shaped honeycomb structure layer is up and down. Staggered mosaic sandwich sandwich structure.

[0023] The composition and percentage weight ratio of the inner structure of the upper skin layer are: 78% polypropylene, 12% talcum powder, 2% polyethylene, 1% maleic acid, 1% calcium carbonate, 1% titanium dioxide , 1% Al2O3, 0.5% Antioxidant 1010, 0.1 UV Absorber UV-327, 0.4% Coupling Agent KH-550, 3% Masterbatch uniformly mixed, dried at 120°C for 2 hours The upper skin layer mixture is obtained.

[0024] The composition of the internal structure of the dimple-shaped honeycomb structure layer and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com