Novel mineral material and preparation method and application thereof

A mineral and new technology, applied in the field of new mineral materials and their preparation, can solve the problems of insufficient compressive strength, tensile strength and bending strength, and achieve the effects of good shock absorption, high precision and good integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

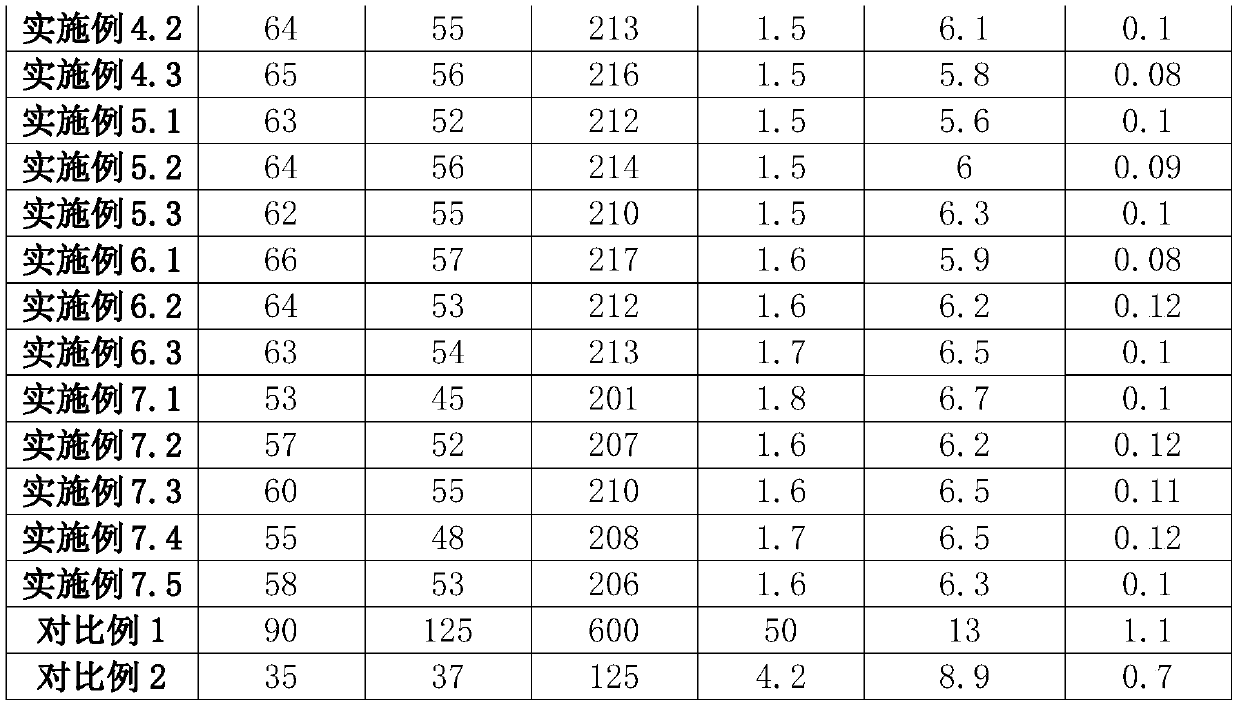

Examples

Embodiment 1

[0032] This embodiment provides a new type of mineral material, which is made of the following raw materials in weight percentage: 80% stone, 5% carbon fiber, 5% ash powder and 10% epoxy resin and curing agent.

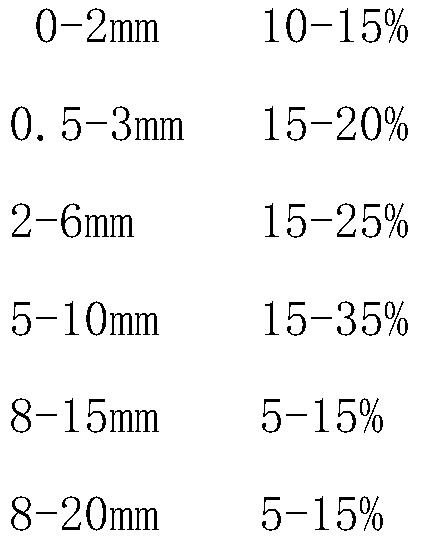

[0033] Among them, the stone material is pebble, and the particle size is 0-2mm 15%, 0.5-3mm 15%, 2-6mm 15%, 5-10mm 15%, 8-15mm 10%, 8-20mm 10%. In this embodiment, the ash powder is coal ash; the epoxy resin is 8% of phenolic type, and the curing agent is 2% of polyetheramine.

[0034] The preparation method is as follows: various constituent materials are prepared according to a certain ratio, and the polymer mineral material can be obtained after being uniformly stirred by a mixer.

[0035] The particle size grade of ashes is special grade. You can also use one grade, the higher the particle size grade of ash powder, the better the effect.

[0036] The mineral material provided in this embodiment can be used in the preparation of numerically controlled lathes, es...

Embodiment 11

[0040] This embodiment provides a new type of mineral material. The difference from Example 1 is that the new type of mineral material is made of the following raw materials in weight percentage: 80% stone, 5% carbon fiber, 5% ash powder and 10% epoxy resin.

Embodiment 12

[0042] This embodiment provides a new type of mineral material. The difference from Example 1 is that the new type of mineral material is made of the following raw materials in weight percentage: 70% stone, 5% carbon fiber, 5% ash powder and 20% epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com