Method for manufacturing metal shield

A metal shielding and electroforming technology, which is applied in the direction of metal layered products, magnetic field/electric field shielding, chemical instruments and methods, etc., to achieve the effect of no internal stress, high resolution and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

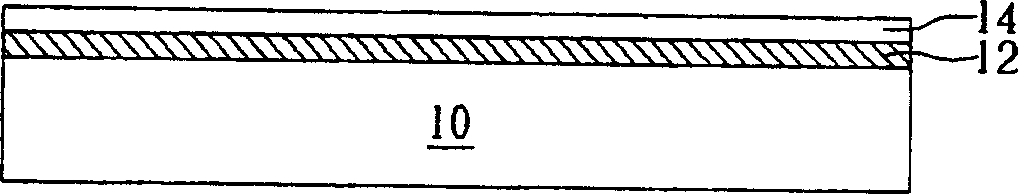

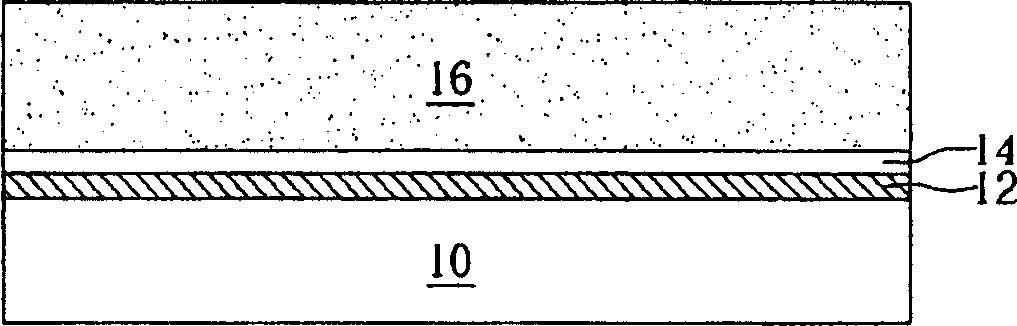

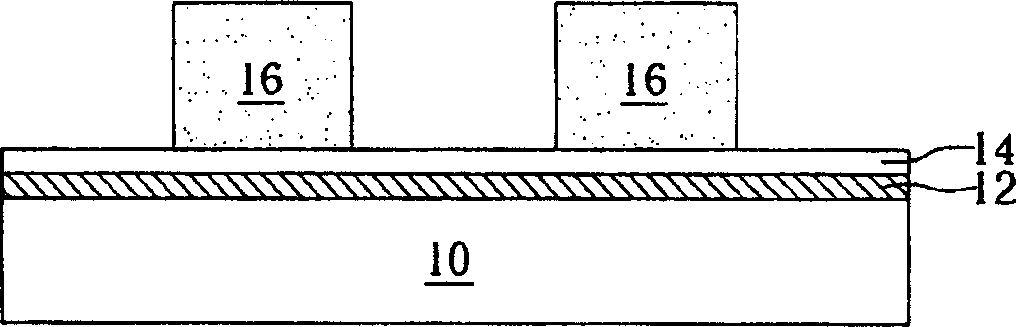

[0012] refer to Figure 1 to Figure 6 , Figure 1 to Figure 6 Schematic diagram of the process of the method for fabricating a high-resolution metal shield of the present invention. Such as figure 1 As shown, firstly, a cleaned substrate 10 is provided, and the material of the substrate 10 can be glass or other materials. Next, a release layer 12 is formed on the surface of the substrate 10 to make the subsequent metal shielding finished product easy to release from the surface of the substrate 10 . In this embodiment, the release layer 12 is a layer of positive or negative film photoresist material, and the thickness is not limited.

[0013] Next, a thin film metal layer 14 is formed on the surface of the release layer 12, and the thin film metal layer 14 is used as an electroforming seed layer for helping the electroforming metal object adhere and grow in the subsequent electroforming process. Wherein, the formation methods of the thin film metal layer 14 include methods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com